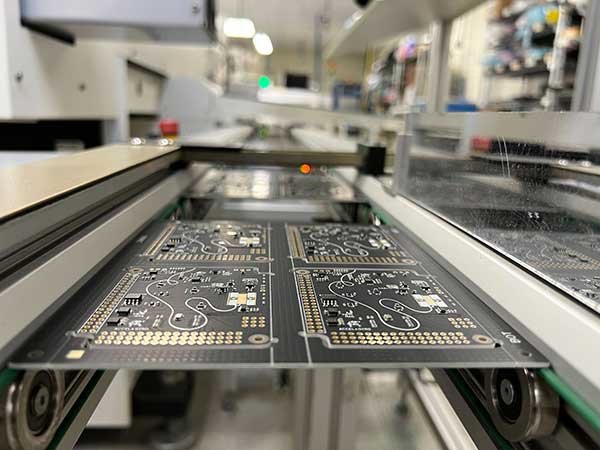

Rapid Prototype PCB Fabrication

Rapid PCB Prototyping Service

JHYPCB offers rapid and reliable PCB prototyping services to meet your specific business needs. With advanced equipment and experienced engineers, we guarantee high-quality PCBs at competitive prices. Contact us today for fast and efficient service you can trust.

Rapid PCB Prototyping: A Game-Changer for the Electronics Industry

At JHYPCB, we specialize in providing rapid PCB prototype services to help hardware startups and engineers quickly test and iterate their designs.

With over 10 years of experience in PCB manufacturing, we understand the importance of fast turnaround times for prototype boards. We are committed to providing high-quality PCB prototypes with industry-leading rapid turnaround times.

Our rapid prototyping services are optimized to deliver PCB boards in just 24-48 hours without compromising quality. This enables designers to quickly test ideas, make improvements, and bring products to market faster.

We utilize advanced manufacturing processes, strict quality control, and efficient supply chain management to achieve rapid turnaround. When every day counts, you can trust the experienced team at JHYPCB to deliver high-quality PCB prototypes rapidly.

With our rapid PCB prototyping services, you can speed up your development cycles, validate designs early and gain a competitive edge. Contact JHYPCB today to learn more about our capabilities!

Rapid PCB prototyping service is designed to help you accelerate innovation and get to market faster.

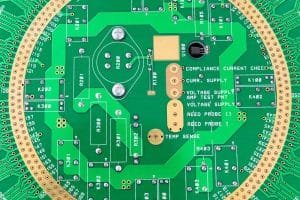

What is PCB Prototyping?

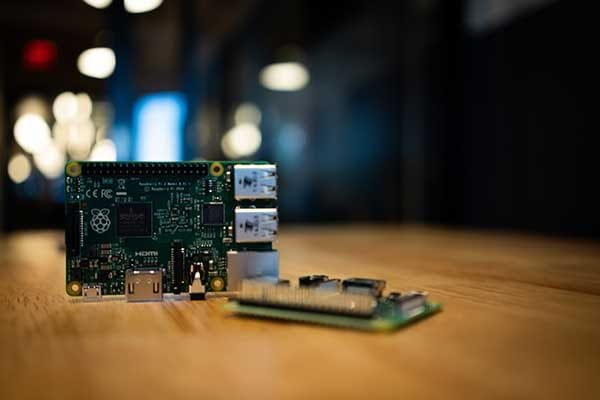

PCB prototype is the physical form of PCB design, which is the pre-production of printed circuit boards before mass production. Generally, PCB prototypes require fewer units, usually 5-100 pieces. The purpose of a PCB prototype is to test to ensure that the design meets the project’s functional requirements.

From the PCB prototype to the product’s final launch, it needs to go through many design modifications and tests. To quickly enter the market, rapid PCB prototyping is very important.

PCB prototype services include bare PCB prototype fabrication and PCB assembly services.

What is Rapid PCB Prototyping?

Rapid PCB prototyping is a quick and cost-effective process of creating a working circuit board prototype. The process can be completed within 24 to 72 hours, allowing engineers and designers to test and validate their designs quickly.

Although PCB prototyping is a basic and very important requirement in the design process, PCB designers and engineers often encounter some challenges, such as many PCB manufacturers not accepting small orders or the lead time being too long, resulting in extended product development cycles, etc. Rapid PCB prototyping service is the best way to solve this kind of problem.

01

What are the Benefits of Our Rapid PCB Prototyping Service?

JHYPCB’s rapid PCB prototyping services offer many benefits that give your projects a competitive edge.

- Faster Design Iterations: Our quick turnaround times allow you to test your PCB designs, identify improvements, and implement changes rapidly. Instead of waiting weeks, you can progress through multiple iterations in days.

- Accelerate Time-to-Market: Getting working prototypes faster enables you to verify and improve your product designs sooner. This allows you to launch new products faster than competitors.

- Early Risk Reduction: Catching design flaws or manufacturing issues early with prototypes greatly reduces project risks and costs. Rapid prototyping prevents wasted time and money.

- Increased Flexibility: The ability to implement modifications quickly with fast prototype turns gives you greater flexibility in design. You can refine PCB characteristics rapidly.

- Confidence Building: Quickly testing your PCB prototype on real hardware gives you confidence that your product will function as intended. This allows a faster transition to production.

With JHYPCB’s rapid prototyping services, you can leverage these benefits to develop products faster, economically, and with less risk. Contact us to discuss how we can accelerate your next project!

02

What are the Rapid PCB Prototyping Applications?

Rapid PCB prototyping is valuable for nearly any electronic design application. However, some industries benefit greatly from rapid PCB prototyping in their development cycles:

- Consumer electronics: prototyping of circuit boards for devices such as smartphones, laptops, cameras, and other consumer electronics.

- Aerospace and Defense: prototyping of printed circuit boards for avionics, satellites, and other mission-critical applications.

- Medical devices: prototyping of PCBs for medical instruments and equipment, such as patient monitoring devices and diagnostic tools.

- Automotive: prototyping of printed circuit boards for automotive electronics, including engine controls, navigation and entertainment systems, and safety features.

- Industrial equipment: prototyping of circuit boards for production equipment, robotics, and automation control systems.

These are just a few examples of rapid PCB prototyping applications. In general, any industry that requires electronic systems or devices can benefit from rapid PCB prototyping.

In conclusion, rapid PCB prototyping is a critical tool for the modern electronics industry and has revolutionized the electronics industry, making it possible to quickly and affordably create working prototypes of circuit boards. It allows designers to quickly validate their ideas, test new designs, and make changes as needed. This speed and flexibility have transformed the development process, allowing companies to bring new products to market faster and more efficiently and has enabled small businesses and startups to compete with larger, established companies.

How Does Rapid PCB Prototyping Work at JHYPCB?

At JHYPCB, we have optimized our entire prototyping process to deliver PCB boards rapidly without compromising on quality.

Once you place your order, our engineering team will review your Gerber files and manufacturing specifications. We put great emphasis on ensuring your files are valid and complete to avoid any delays or errors.

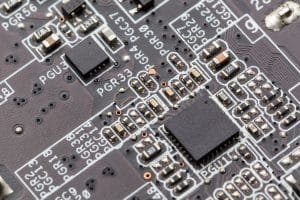

Next, your PCB design goes into prototyping production. We utilize advanced equipment and streamlined workflows to complete the PCB prototype fabrication and PCB assembly process rapidly. Our factory facilities run 24/7 to meet the tightest turnaround requirements.

Throughout the assembly process, we perform rigorous quality control checks at multiple stages. This includes automated optical inspection (AOI) to examine PCBs for defects and quality issues.

Most prototype boards are shipped within 24-48 hours of order placement. We offer various domestic and international shipping options, including DHL, FedEx and UPS to deliver your prototypes on time.

You’ll receive email notifications at every step, so you can track order status conveniently. Our responsive customer support team is also available to answer any questions.

At JHYPCB, every detail is engineered for speed without compromising on quality. With strict processes guaranteeing rapid turnaround times, you can get PCB prototype boards delivered lighting fast.

We have provided rapid PCB prototyping service for customers in many industries.

Rapid PCB Prototyping Manufacturer in China

JHYPCB is an experienced rapid PCB prototyping service provider in China. We pride ourselves on meeting customers’ rapid PCB prototyping needs.

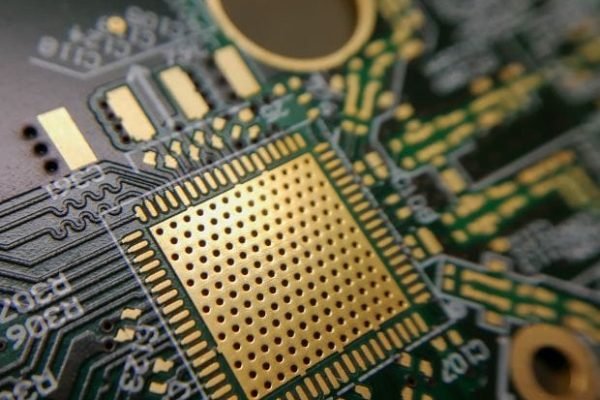

Whether you need simple single-layer and double-sided PCB or complex multi-layer PCB prototypes, we can provide you with rapid PCB prototyping service at affordable prices and first-class quality.

Our rapid PCB prototyping service can satisfy multiple elements of customized circuit boards from amateurs to large electronic product manufacturers, including material, board type, copper thickness, board thickness, surface finish, impedance control, etc.

Since we offer in-house PCB prototyping services, we can offer fast turnaround times.

One-Stop PCB Services from prototyping to assembly

Bare PCB Prototype

Material options, up to 64 layers, and surface finish options are available.

Turnkey PCB Assembly

SMT, THT PCB assembly. Turnkey/partial, Quick, reliable, and affordable.

SMT Stencil & Components

Laser cut, frame or frameless, Various size options, thicknesses, available.

Why Choose us for Rapid PCB Prototying?

If you are looking for rapid PCB prototyping services, JHYPCB is the right partner.

Instant Quote

Quick Turnaround

Over 10 Years of Experience

On-Time Delivery

Competitive Pricing

Market-leading services

First-class Quality

Excellent Fabrication Capability

Rapid Prototyping PCB Assembly

From design to production, JHYPCB provides full-service and one-stop PCB assembly from rapid prototype to quick turnaround small quantity production. Whether you need quick-turn PCB assembly or need a rapid bare PCB prototype fabrication service, we are here to help you to prepare a cost-effective and rapid PCB prototype for PCB manufacturing or assembly.

- No MOQ

- Low Quantity PCB Assembly

- SMT & THT Assembly

- Fine Pitch Component Insertion

- 3-7 Days Rapid Prototype PCB Assembly

- Quick Response

- 100%% E-Testing, X-ray & AOI

- Functional Testing

Ready to get started with rapid PCB prototyping?

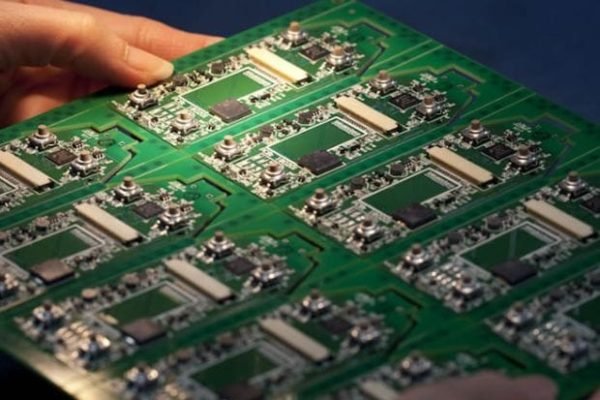

JHYPCB offers a range of advantages for both rapid PCB prototyping and mass production. For rapid PCB prototyping, JHYPCB specializes in small-volume PCB manufacturing with quick turnaround times. This means that we can produce low quantities of PCBs within a short timeframe, ensuring you get their prototypes as quickly as possible.

For bulk production, JHYPCB handles high-volume PCB manufacturing with ease. Thanks to our advanced production facilities and efficient production processes, we can produce PCBs in large quantities without sacrificing on quality or turnaround time. In fact, we can easily handle orders of up to 100,000 units.

By using JHYPCB for your PCB needs, you can enjoy various benefits including competitive pricing, high-quality PCBs, fast turnaround times, and reliable customer service. Our team of experienced professionals is dedicated to ensuring that every customer is satisfied with their order, no matter the size or complexity of the project. Plus, with our commitment to continuous improvement and innovation, you can trust that we are constantly striving to deliver the best possible outcomes for our customers.

Overall, whether you need a small batch of prototypes or a large volume of PCBs for a complex project, JHYPCB has the expertise, resources, and commitment to deliver high-quality results, quickly and reliably.

If you have any questions about our PCB manufacturing service or need help, please get in touch with us.

An Easy Order Process

How to order?

- Upload your Gerber date or send it to sales@pcbjhy.com

- Get a fast quotation

- Payment

- Production

- Quality control & Packing

- Delivery

Place an Rapid PCB Prototying Order

What Files for rapid PCB prototyping?

- Gerber File

- PCB specification: Quantity, Shipping Address, Material, Copper Thickness, Board Thickness, Surface Finish, Solder Mask Color, and other specific requirements.

- BOM (Bill of Materials) for Rapid PCB Assembly

FAQs

Frequently Asked Questions

How long does it take to get my PCB prototypes?

Our standard turn time for PCB prototype orders is 24-48 hours. We also offer an expedited 12-hour build time for urgent orders.

What materials are used in rapid PCB prototyping?

Rapid PCB prototypes are usually made of materials like FR-4, CEM-1, or polyimide. These materials are chosen for their durability, flexibility, and suitability for high-speed circuit designs.

Are rapid PCB prototypes suitable for mass production?

Rapid PCB prototypes are not typically suitable for mass production. They are meant to be used as a tool for testing and validation, and any necessary changes to the design can be made before mass production begins.

How much does it cost to produce a rapid PCB prototype?

The cost of producing a rapid PCB prototype varies depending on the complexity of the design and the quantity of prototypes needed. In general, rapid PCB prototypes are more expensive than mass PCB manufacturing processes.

Can rapid PCB prototyping be used for high-volume production runs?

Rapid PCB prototypes are not designed for high-volume production runs. They are meant for testing and validation of the design and may not have the same level of durability or accuracy as the final product. For high-volume production runs, a different manufacturing process may be necessary.

What is the maximum size of a rapid PCB prototype?

The maximum size of a rapid PCB prototype depends on the specific manufacturing process and the availability of materials. In general, rapid PCB prototypes can be produced in sizes up to 18 x 24 inches or larger.

Can rapid PCB prototypes be used for multi-layer PCB boards?

Yes, rapid PCB prototypes can be used for multi-layer PCB boards. The process of producing multi-layer PCB boards is more complex, but it is possible to produce prototypes with multiple layers of copper, insulation, and other materials.

What is the difference between rapid PCB prototyping and traditional PCB manufacturing?

Traditional PCB manufacturing is a slow and labor-intensive process that typically takes several weeks to complete. Rapid PCB prototyping, on the other hand, is a faster and more efficient process that produces functional prototypes in a matter of days.

What design files do you need for PCB fabrication?

We accept Gerber files, drilling files, bill of materials, and centroid files for PCB prototyping orders. Our engineers can also work with Altium, Cadence, and other native CAD files.

What PCB layers and features can you manufacture?

We can fabricate boards with up to 64 layers. Our capabilities support trace/space down to 3/3 mil, impedance control, HDI, via-in-pad, gold fingers, and flexible PCBs.

Do you ship worldwide?

Yes, we ship PCB prototype orders worldwide using major couriers like DHL, FedEx, and UPS. We have an extensive global customer base.

Do you sign NDAs?

Yes, we will sign NDAs as needed to protect your confidential designs and IP. Please contact us to arrange.

Get in touch with our team if you have any other questions! We are committed to making PCB prototyping easy and helping you bring your products faster to market.