Frequently Asked Questions

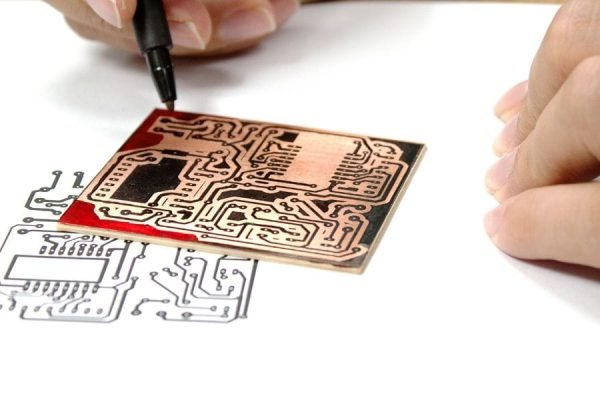

A PCB prototype is a sample circuit board that is created to test the design and functionality of a circuit before mass production.

Creating a low-cost PCB prototype is important because it helps identify and fix design issues cost-effectively before mass production.

The cost of a cheap PCB prototype can vary depending on the manufacturer, the number of layers, and the size of the board. Generally, a cheap PCB prototype can cost between $5 to $50.

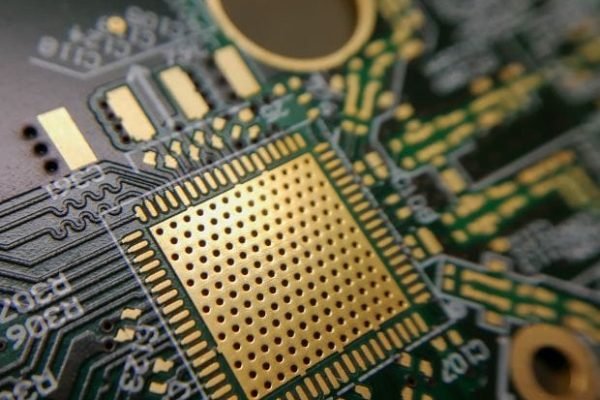

The cost of a PCB prototype can be affected by factors such as the number of layers, the size of the board, the type of material used, and the manufacturing process.

Some tips for getting a cheap PCB prototype include designing a simple board, reducing the number of layers, using standard materials, and using a PCB manufacturer that offers discounts for bulk orders.

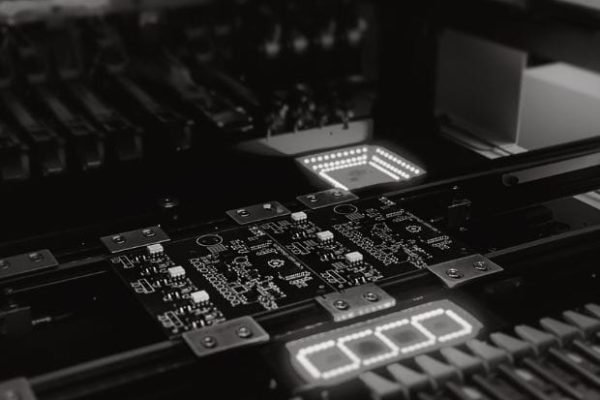

The time it takes to produce a PCB prototype can vary depending on the complexity of the design and the manufacturer. Generally, it can take between 3 to 7 days to produce a PCB prototype.

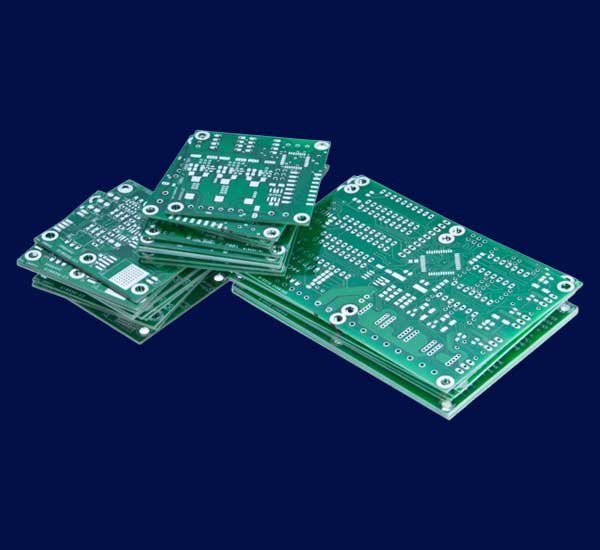

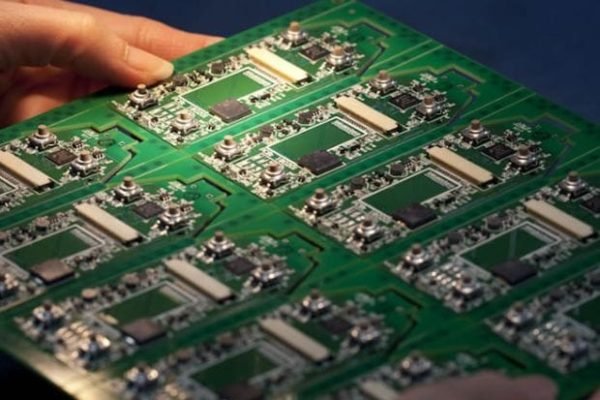

The minimum order quantity for a PCB prototype can vary depending on the manufacturer, but generally, it can range from 1 to 10 units.

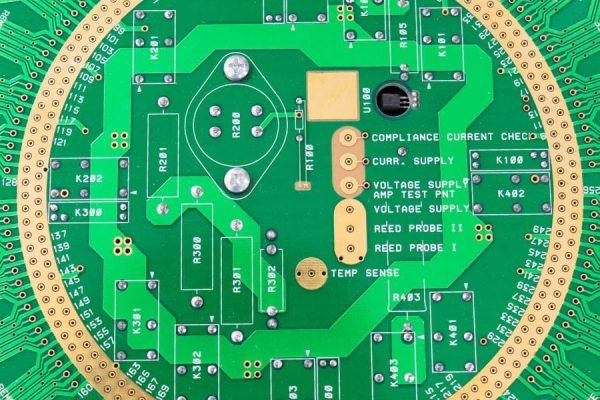

The file formats needed for PCB prototyping include Gerber files, drill files, and bill of materials (BOM) for prototype PCB assembly.

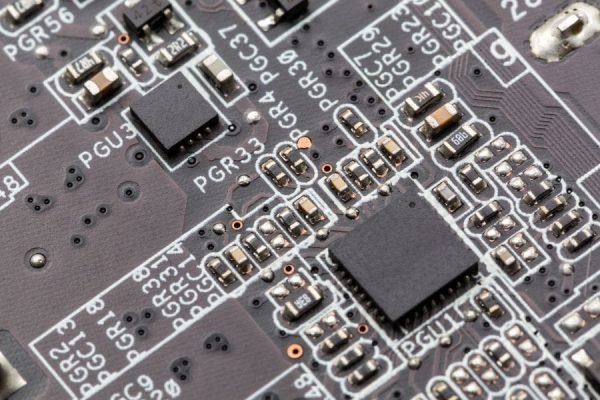

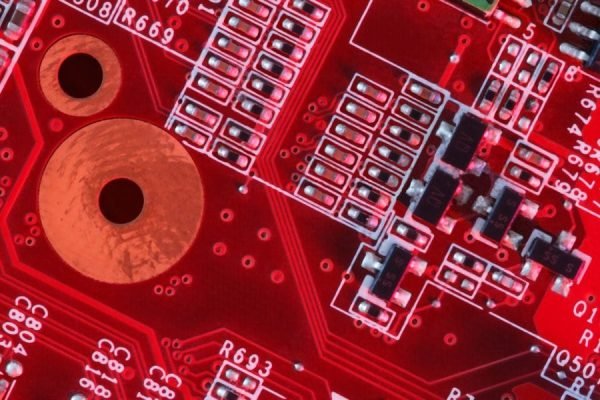

There are different types of PCB prototypes available, including single-sided, double-sided, and multi-layered PCB prototypes.

When choosing a PCB prototype manufacturer, consider factors such as the manufacturer’s experience, pricing, lead times, and quality of the finished product.

Some PCB prototype assembly options include hand-soldering, automated pick-and-place machines, and reflow ovens.

To ensure the quality of your PCB prototype, consider factors such as the accuracy of the manufacturing process, the use of high-quality materials, and proper testing and inspection of the finished product.