High Current PCBs Manufacturing Service

Heavy/Thick Copper PCB Manufacturer

We are a leading PCB manufacturer in the prototyping, fabrication, assembly of heavy copper PCB boards.

When fabricating heavy copper PCB or thick copper PCB boards, great expertise is needed to produce the right product. Due to the unique benefits of heavy copper PCB, a lot of power electronics are being produced with this material. As our society advances, the demand for thick copper PCB boards increases. Generally, heavy copper PCB boards can be used to create complex circuits within a constrained space. They are also used because of their heat dissipation and high current abilities.

An overview of heavy copper PCB

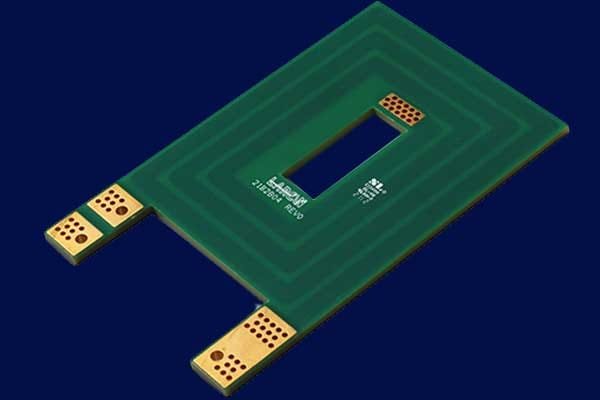

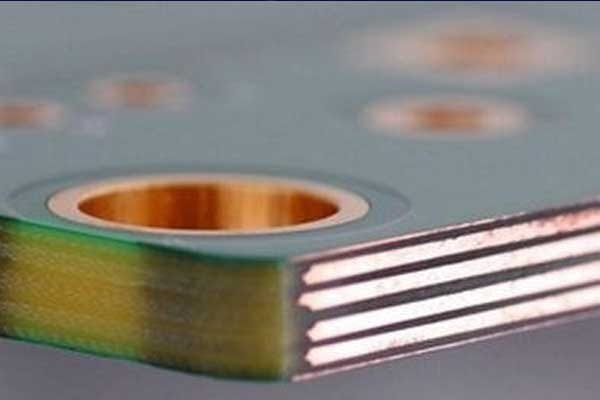

A heavy copper PCB board is a type of printed circuit board which is known to feature 3 or more ounces of copper on the PCB’s internal and external layers. This type of circuit board is also known as a thick copper PCB or extreme copper PCB. We have a wide range of circuits that feature over 4 or more ounces per square foot of copper known as heavy copper PCB boards. Heavy copper PCB boards are known for their enhanced copper weights. They also have thicker plating materials and the right substrate elements that are featured in the through-holes. This can easily help to transform any weak PCB into a dependable and long-lasting wiring platform. The use of heavy copper conductors in a board can considerably increase the thickness of the PCB. During the circuit design, the thickness of the copper needs to be considered carefully. Extreme copper is a type of copper that features between 20 and 200 ounces of copper for every square foot.

The benefits of using heavy copper PCBs

You can rely on engineering properties to help create various possibilities and value with all your products. This is possible due to the various range of benefits that the product feature. One of the core benefits of the heavy copper boards is their tendency to withstand continuous exposure to very high currents, increased temperatures, and frequent thermal cycling. These hazards have the potential to cause damage to a regular PCB in a matter of seconds. Heavy copper boards are known for their high tolerance ability. This is why they can be used in a variety of applications in extreme conditions such as the aerospace and defence industry products. Our heavy copper boards are:

- Quality boards that feature several weights of copper used in the same circuitry layer

- They have more endurance against thermal strains

- Their ability to carry more current is increased substantially

- Their mechanical strengths at the connector sites are increased.

- They fully utilize exotic materials while avoiding circuit failure

Applications of heavy copper PCBs

Our heavy copper boards can be fabricated to be used for a variety of purposes. They can be used in such applications as power converters, high-power distribution systems, heat dissipation, planar transformers, etc. Due to the benefits of heavy copper boards, they are used widely in industrial, military, automotive, and computer systems. In addition, heavy copper boards are applied in:

- Solar panel manufacturers and so on

- Automotive industry

- Welding equipment

- Power distribution

- Power converters

- Power supplies

How to choose PCB Copper Thickness?

Choosing the right copper thickness for a PCB is an important design decision that can impact the performance and reliability of the board. Here are some factors to consider when selecting the copper thickness for a PCB:

Current carrying capacity: The thickness of the copper layer impacts the current carrying capacity of the PCB. Thicker copper layers can handle higher current levels without overheating or damaging the board.

Thermal management: The thickness of the copper layer also affects the thermal management capabilities of the PCB. Thicker copper layers have better heat dissipation properties and can help dissipate heat more effectively from the components.

Trace width: The thickness of the copper layer is related to the width of the traces on the PCB. Thicker copper layers can support wider traces, which can help reduce resistance and improve current carrying capacity.

Manufacturing capabilities: The thickness of the copper layer may be limited by the manufacturing capabilities of the PCB manufacturer. Thicker copper layers may require specialized manufacturing processes, which can increase the cost and lead time of the PCB.

Cost: The thickness of the copper layer is a factor in the cost of the PCB. Thicker copper layers generally cost more than thinner layers, so the choice of copper thickness should be balanced with the requirements of the application and the available budget.

In general, a copper thickness of 1 oz (35 microns) is sufficient for most low-power applications. For high-power applications, a copper thickness of 2 oz (70 microns) or more may be required. It is recommended to consult with the PCB manufacturer and consider the specific requirements of the application before choosing the copper thickness for a PCB.

Performance Metrics and Testing of Heavy Copper PCBs

Heavy copper PCBs have unique properties that make them suitable for high-power and high-temperature applications. Here are some key performance metrics and testing methods to evaluate heavy copper PCBs:

- Copper Thickness: The copper thickness in heavy copper PCBs is typically greater than 3 oz (105 microns) and can range up to 20 oz (700 microns). The thickness of copper impacts the current carrying capacity and heat dissipation capability of the PCB. The thickness can be measured using a micrometer or eddy current testing.

- Current Carrying Capacity: Heavy copper PCBs have a higher current carrying capacity than traditional PCBs due to the thicker copper layers. The current carrying capacity can be determined by performing a current carrying test at various temperatures.

- Thermal Management: Heavy copper PCBs have better heat dissipation capabilities compared to traditional PCBs due to the thicker copper layers. Thermal management can be evaluated by performing a thermal imaging test or thermal resistance measurement.

- Electrical Performance: Heavy copper PCBs may have different electrical characteristics than traditional PCBs due to the thicker copper layers. Electrical performance can be tested by measuring impedance, signal integrity, and capacitance.

- Solderability: The thick copper layers in heavy copper PCBs may pose challenges for soldering. Solderability can be evaluated by performing a solderability test.

The importance of copper weights in PCB fabrication

Due to a wide range of customer demands, we have been able to complete various PCB fabrication projects that demand specific weights of copper. We have a wide range of copper weight selections that can suit the specific needs of your projects.

One-stop heavy copper PCB fabrication for all your needs

When you need a heavy copper board to be fabricated according to your needs, you need to rely on our advanced manufacturing capability. We offer some of the best solutions in terms of the fabrication of heavy copper boards. We boast of superior engineering technology that can be used to fabricate and assemble your heavy copper boards according to your unique specifications. We have the best technology that can help you take all your “design-to-market” PCB fabrication needs and make them a reality.

We have the technology required for the fabrication of heavy copper

One reason we are very different from other PCB manufacturers is our unique and patented heavy copper board. The fabrication of this type of printed circuit board involves the use of a special technology. This is why such boards are very expensive to produce in comparison to other regular boards. With our heavy copper boards, the fabrication price may not be cheap, but we guarantee quality and value with all our products.

Remarkable PCB manufacturing expertise

Due to our advanced manufacturing capabilities, we can meet the various needs of our customers. We have many years of experience in the manufacture of various special and highly complex PCB materials. Apart from our manufacturing expertise, we can also offer you amazing PCB assembly services and solutions. Our job is to help our customers stay ahead of their industries.

About our manufacturing expertise

You can get heavy copper PCB fabrication solutions that suit your business needs. We have been among the best PCB/PCB manufacturers that cater to the needs of many of our clients. We are a leading manufacturer when it comes to the design, assembly, prototyping, and manufacturing of heavy copper boards. Our decades of experience speak for us and endear us to various leading electronic brands from across the world. With hundreds of satisfied clients, we look to help more customers have a taste of superior heavy copper board fabrication expertise. For many years, we have been a leading manufacturer of heavy copper boards. All our boards are fabricated with the highest quality and standards. Also, our finished products are meant to meet various product standards and regulatory policies.

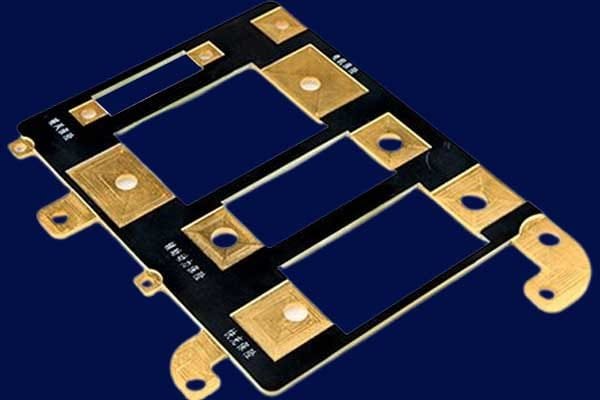

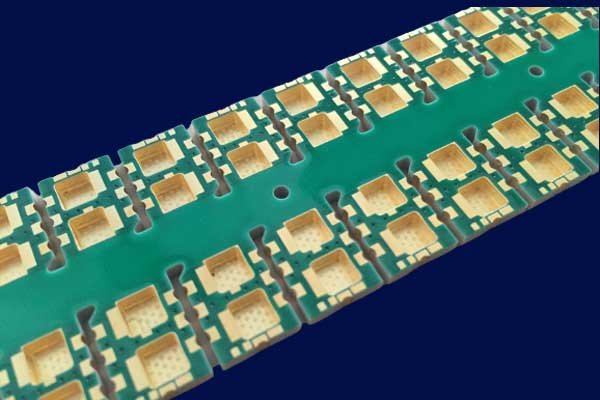

Heavy Copper PCB Example

4 oz Copper PCB

8 oz Copper PCB

10 oz Copper PCB

20 oz Copper PCB

Heavy Copper PCB FAQs

What is a heavy copper PCB?

- A heavy copper PCB is a type of printed circuit board that has thick copper layers, typically ranging from 3 oz to 20 oz or more.

- The thick copper layers provide several benefits, such as increased current carrying capacity, improved thermal management, and increased mechanical strength.

What is the Thickest Copper PCB?

- The thickest copper PCB can have a copper thickness of up to 20 oz (approximately 700 microns). This type of PCB is known as a heavy copper PCB, and it is used for high-power and high-current applications that require high thermal conductivity and durability.

- Heavy copper PCBs have several benefits over traditional PCBs, including increased current carrying capacity, improved thermal management, and increased mechanical strength. They are typically used in power supplies, automotive electronics, industrial equipment, and aerospace applications.

- Manufacturing heavy copper PCBs can be challenging due to the thickness of the copper layers. Specialized manufacturing processes may be required, such as etching with a high-pressure water jet or laser drilling. It is important to work with an experienced PCB manufacturer who has the capability to produce heavy copper PCBs to ensure the highest quality and reliability of the final product.

How Thick is Heavy Copper PCB?

Heavy copper PCBs are characterized by their thick copper layers, which can range from 3 oz (approximately 105 microns) to 20 oz (approximately 700 microns) or more. The thickness of the copper layer depends on the specific requirements of the application and the current carrying capacity and thermal management needs of the board.

In general, heavy copper PCBs have a minimum copper thickness of 3 oz (105 microns), which is significantly thicker than the standard 1 oz (35 microns) copper thickness used in traditional PCBs. The copper layers in heavy copper PCBs are typically several times thicker than the base material, such as FR-4, used in the PCB.

What is the Copper Weight of PCB?

The copper weight of a PCB refers to the thickness of the copper layer on the board, and it is typically measured in ounces per square foot (oz/ft2) or microns (µm). The copper weight of a PCB determines the current carrying capacity, thermal management, and mechanical strength of the board.

In general, PCB copper weight ranges from 0.5 oz (approximately 17.5 microns) to 6 oz (approximately 210 microns) or more. The most common copper weight for standard PCBs is 1 oz (approximately 35 microns) per square foot. However, for high-power and high-temperature applications, thicker copper weights may be required to handle the increased current levels and dissipate heat effectively.

How Thick is 1 oz of Copper PCB?

1 oz of copper PCB refers to the thickness of the copper layer on the board, which is approximately 35 microns or 1.4 mils. This is the standard copper weight used in most PCBs.

The total thickness of a typical PCB can range from 0.2 mm to 3 mm or more, depending on the specific design and requirements.

How is a heavy copper PCB manufactured?

- Manufacturing a heavy copper PCB requires specialized processes, such as etching with a high-pressure water jet or laser drilling.

- The process involves depositing a thick layer of copper on the substrate, and then selectively removing the copper to create the desired circuit pattern.

What factors should be considered when designing a heavy copper PCB?

- The design of a heavy copper PCB should take into account the thickness of the copper layer, as well as the required current carrying capacity, thermal management, and mechanical strength.

- Other factors to consider include the size and shape of the board, the number of layers, and the types of components and connections required.

How does the cost of a heavy copper PCB compare to a standard PCB?

- The cost of a heavy copper PCB is generally higher than that of a standard PCB, due to the specialized manufacturing processes and materials required.

- However, the benefits of a heavy copper PCB, such as increased reliability and durability, may justify the higher cost for certain applications.