Flexible PCB Manufacturing Services

Single Sided Flexible PCB Manufacturing Service

Looking for Single Sided Flexible PCB manufacturing services? We provide high-quality and cost-effective solutions for your flexible PCB needs. Contact us today!

Single Layer FPC

What is Single Sided Flex PCB?

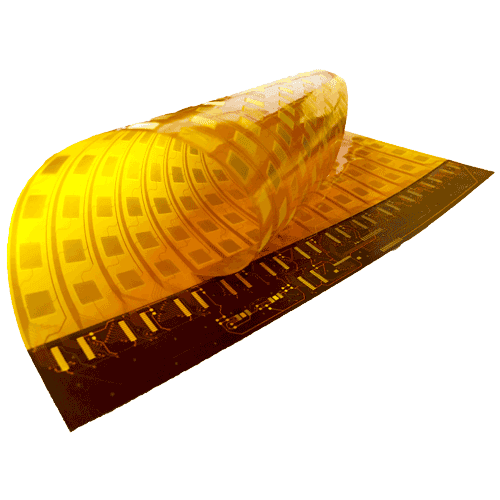

A single sided flexible printed circuit board (single sided flex PCB or single layer FPC) features a conductive material like copper traces on just one side of the flexible substrate. The other side is covered with an insulating flexible material, enabling the single layer flexible circuit to bend and flex. The conductive traces on the flexible PCB are designed to bend and flex without damaging the board or the components mounted on it, allowing the board to conform to various shapes and sizes. This type of PCB is commonly used in applications that require flexibility, such as wearable electronics, medical devices, and automotive systems. Single Sided Flexible PCBs have many advantages over traditional rigid PCBs, including their ability to save space, reduce weight, and improve reliability. They are typically more expensive to manufacture than single-sided rigid PCBs, but their flexibility and versatility make them ideal for many types of applications.

Single Sided FPC Stackup

Structure of Single-layer FPC

The typical construction of a single-layer flexible PCB comprises a flexible base substrate made from polyimide or polyester films. An adhesive layer bonds the conductive copper traces, etched in a circuit pattern, onto this flexible substrate. To protect the conductive layer, a solder mask or coverlay film provides insulation.

Single Sided Flexible Circuit Benefits

Advantages of Single Sided Flexible PCBs

Single Sided Flexible PCBs offer many advantages over traditional rigid PCBs, including their bendability, space-saving design, cost-effectiveness, high reliability, improved signal integrity, and ease of assembly. These advantages make them an excellent choice for applications where flexibility, durability, and efficiency are essential. If you are looking for a high-quality and cost-effective solution for your PCB needs, Single Sided Flexible PCBs may be the ideal choice for you.

Compared to rigid PCB counterparts, key benefits of single-sided flex PCBs include:

Unmatched Flexing Capabilities

Single-sided flexible circuits can repeatedly bend and conform to various shapes without cracking or damage.

Space and Weight Savings

The ultra-thin, lightweight design of single-sided flex PCBs enables compact form factors and portable applications.

Cost-Effectiveness

Manufacturing single layer FPCs is generally more economical versus multi-layer rigid boards.

Durability and Reliability

The flexible nature renders single-sided flex PCBs resistant to vibrations, temperature fluctuations, and harsh environments.

High Signal Integrity

The simplified single layer construction minimizes signal interference and electromagnetic effects.

Streamlined Assembly

With components on just one side, single layer flexible circuits ease manufacturing and assembly processes.

Single Layer Flexible PCB Applications

Application of Single Sided Flexible PCBs

Single Sided Flexible PCBs are highly versatile and find application across various industries. They are widely used in medical devices, automotive systems, consumer electronics, aerospace, and industrial equipment due to their compact size, flexibility, durability, and high reliability. Their ability to withstand harsh environmental conditions, temperature fluctuations, and vibration makes them an ideal choice for demanding applications. Single Sided Flexible PCBs offer excellent signal integrity and ease of assembly, making them a popular choice for manufacturers who value cost-effectiveness without compromising on quality.

How to Make Single Layer Flexible PCB?

Manufacturing Process of Single Sided Flexible PCBs

Single Sided Flexible PCBs are manufactured using the following processes:

Material Selection: The materials used for Single Sided Flexible PCBs include flexible substrates, adhesives, and conductive materials such as copper foils.

Fabrication Process: The fabrication process for Single Sided Flexible PCBs involves several steps such as cleaning the substrate, laminating the substrate with copper foil, etching the copper layer to form the desired circuit pattern, drilling holes for components, applying a solder mask and screen printing the legends.

Printing Technology: Single Sided Flexible PCBs are typically manufactured using screen printing technology, which involves applying ink through a stencil onto the substrate. This technique allows for precise placement of the ink and is suitable for printing large areas.

Overall, the manufacturing process for Single Sided Flexible PCBs is relatively simple and cost-effective, making them an ideal choice for applications where cost and flexibility are critical factors. The use of advanced materials and printing technologies ensures that Single Sided Flexible PCBs meet high-quality standards and are suitable for use in a wide range of applications.

Flexible PCB Manufacturer in China

Flexible PCB Manufacturing Service

We are a leading manufacturer of Flexible PCBs with years of experience in the industry. Our team comprises highly skilled professionals committed to providing our customers with the best possible service. Our Flexible PCB Manufacturing Service offers high-quality and cost-effective solutions for all your Flexible PCB needs.

Service Scope: We offer a comprehensive range of services, including single-sided, double-sided, and multilayer flexible circuit board fabrication, assembly, and testing services. Our services are tailored to meet the specific needs of our customers, ensuring that we provide the most efficient and cost-effective solutions.

Fabrication Process: Our fabrication process is designed to ensure that our Flexible PCBs meet the highest quality standards. We use advanced materials and manufacturing techniques to ensure that our products are durable, reliable, and meet the most demanding specifications.

Technical Support: We provide comprehensive technical support to our customers, including design assistance, prototyping, and testing services. Our team of experts is always on hand to answer any questions or concerns you may have, ensuring that you get the best possible service and support.

Contact JHYPCB For Your High-quality Flexible PCB

Ready to get started on your Single Sided Flexible PCB project? Contact us today at sales@pcbjhy.com to learn more about our services and receive a quote.

To streamline the process, you can also fill out our online inquiry form, providing us with the necessary details about your project. Our team will get back to you promptly with a customized quote and answer any questions you may have.

Don’t hesitate, contact us today to start your Single Sided Flexible PCB project with the experts at our Flexible PCB Manufacturing Service.