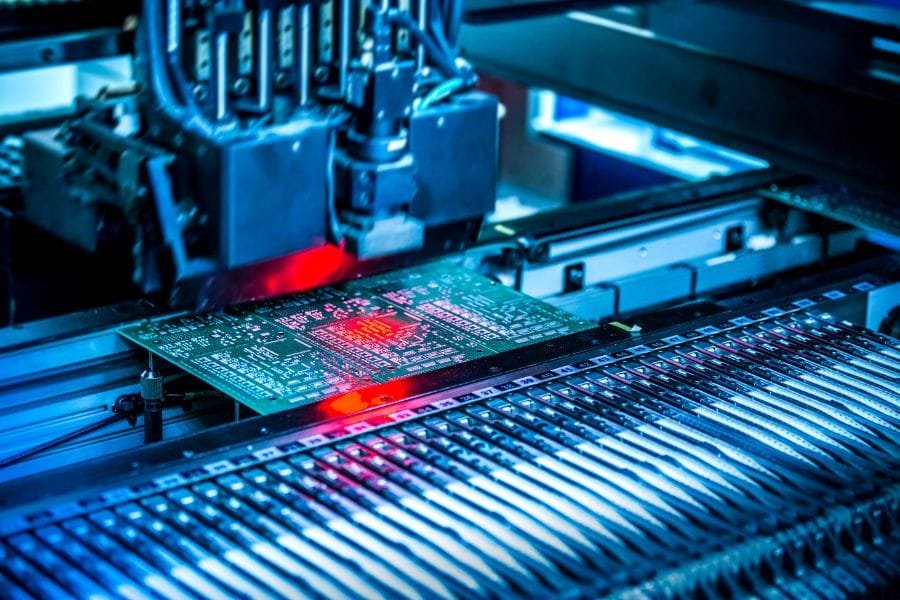

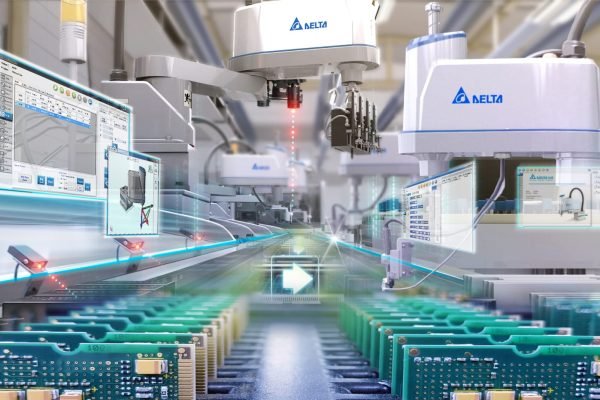

SMT Assembly Advantages

Benefits of SMT Assembly

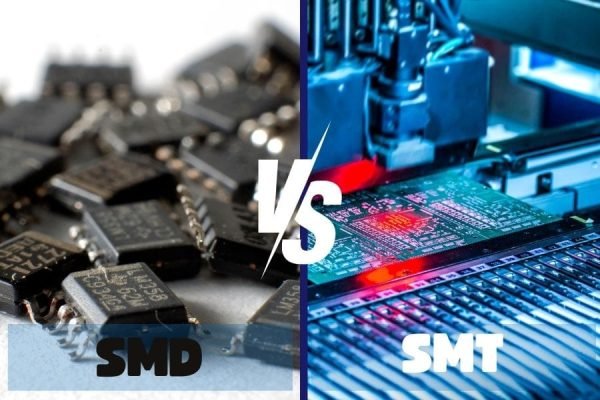

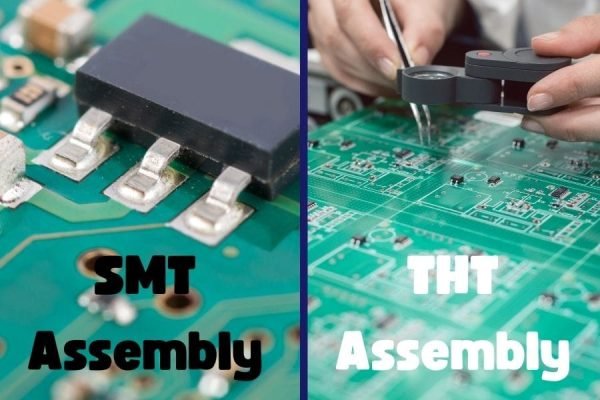

SMT assembly provides a more efficient and cost-effective method for assembling electronic circuits, while also offering improved electrical performance and smaller, lighter-end products.

Learn more about The Pros and Cons of SMT PCB Assembly

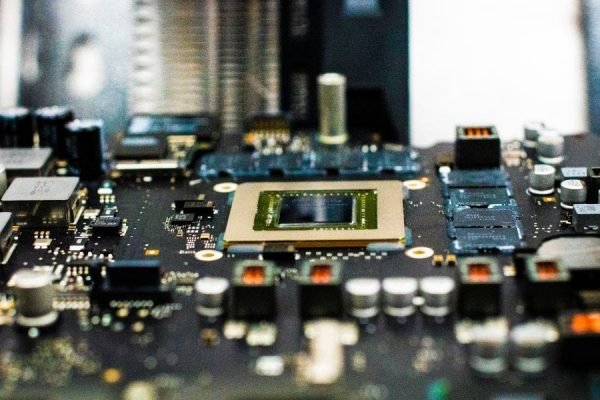

Size and weight reduction

SMT components are smaller and lighter, which allows for smaller PCBs and more compact electronic devices.

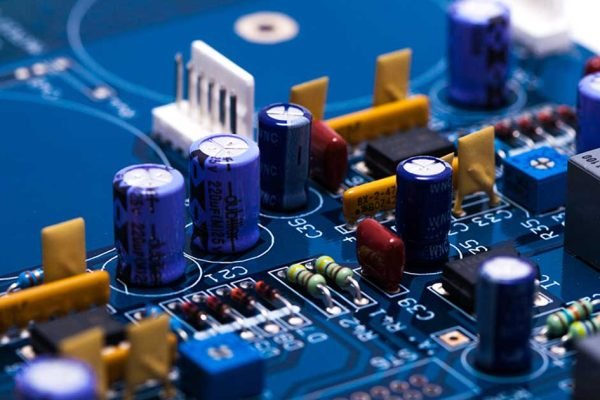

Higher component density

SMT assembly allows for higher component density on the PCB, which means that more components can be placed on a smaller area of the board.