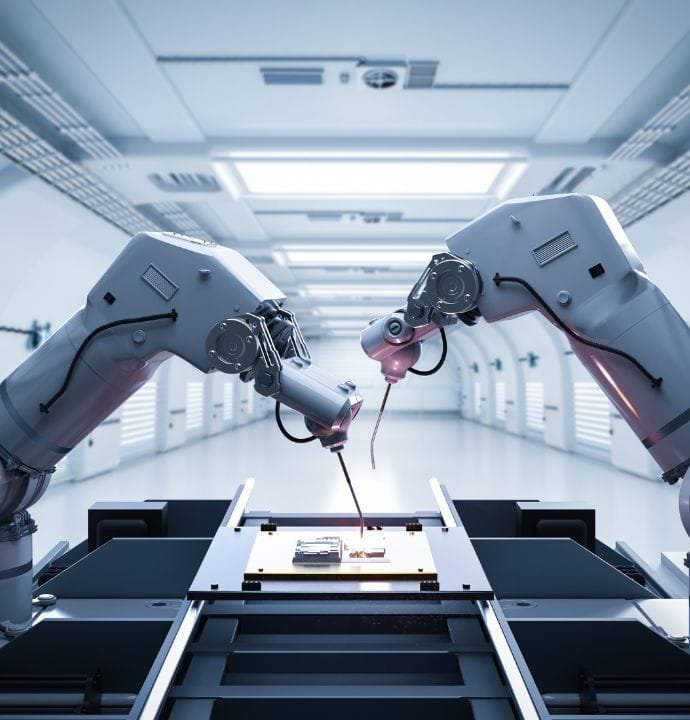

PCB Electronic Manufacturing Services

PCB for Industrial Automation and Control

JHYPCB offers high-quality PCB manufacturing services for industrial automation and control systems. Learn about the design and assembly considerations as well as applications of PCBs in this industry. Explore our capabilities to see how we can meet your PCB manufacturing needs.

PCB Manufacturer for Industrial Automation and Control Systems

The industrial automation and control industry is moving towards automation and digitization. PCBs are an essential component of industrial automation and control systems as they provide reliable circuit connections and signal transmission. JHYPCB is a professional PCB manufacturer with years of experience in the industrial automation and control field. We offer high-quality PCB design, fabrication, assembly, testing, and other services to meet the diverse needs of our customers. If you need customized PCBs for industrial automation and control systems, we can help you complete the entire production process from design to delivery. As an expert and manufacturer in this field, we are committed to delivering high-quality PCB products and services to our customers.

Types of PCBs used in industrial automation and control

The industrial automation and control industry is moving towards automation and digitization. PCBs are an essential component of industrial automation and control systems as they provide reliable circuit connections and signal transmission.

To meet the diverse needs of customers in this industry, PCBs come in various types including rigid, flexible, rigid-flex, HDI, metal core, ceramic, multi-layer, and backplane PCBs. The choice of PCB type depends on the specific application requirements.

Rigid PCBs: These are the most common type of PCBs used in industrial automation and control. They have a rigid form factor that makes them suitable for applications where stability is important.

Flexible PCBs: These PCBs are designed to be flexible and adaptable to various shapes and sizes. They allow for greater freedom in design than rigid PCBs and can be installed in tight spaces or in applications where vibration or movement may cause damage to rigid boards.

Rigid-flex PCBs: These PCBs combine the best of both worlds by combining the rigid and flexible circuitry within a single board. Rigid-flex PCBs are often used in complex applications where space is limited, and durability and reliability are critical.

High-density interconnect (HDI) PCBs: These PCBs have a high circuit density and are ideal for applications where space is limited and reliability is critical. They offer improved signal integrity and reduced noise interference.

Metal core PCBs: These PCBs have a metal core, typically aluminum, that helps dissipate heat generated by power components. They are ideal for applications such as LED lighting, power supplies, and motor controllers.

Ceramic PCBs: These PCBs are made from ceramic materials and offer excellent electrical insulation, thermal conductivity, and mechanical stability. They are often used in high-temperature and high-power applications.

Multi-layer PCBs: These PCBs consist of multiple layers of conductive material separated by insulating layers. They are ideal for applications that require complex circuitry and high-density interconnections.

PCB design considerations for industrial automation and control

PCB design is a crucial aspect of PCB manufacturing, especially for industrial automation and control applications. The following are the key design considerations for PCBs used in industrial automation and control:

Component placement and trace routing: It is important to ensure that components are placed optimally on the board to minimize signal interference and ensure proper heat dissipation. Trace routing should be carefully designed to avoid crosstalk and signal loss.

Thermal management and heat dissipation: Some industrial automation and control applications involve high power components that generate significant heat during operation. Proper thermal management is critical to prevent damage to the PCB and other components in the system. This can be achieved through the use of heat sinks, thermal vias, and other cooling techniques.

Signal integrity and noise reduction: Signal integrity is essential for ensuring proper communication and data transfer within the system. Careful PCB design can help reduce noise interference from external sources such as electromagnetic interference (EMI) and radio frequency interference (RFI). Techniques such as shielding, filtering, and grounding can be employed to reduce noise and improve signal integrity.

EMC/EMI shielding: Industrial automation and control systems are often located in harsh environments that are subject to electromagnetic interference. Thus, it is important to incorporate shielding into the design to protect the system from interference and ensure reliable operation.

Board size and form factor considerations: The size and shape of the PCB should be carefully considered to ensure compatibility with the enclosure or space where it will be installed. In addition, the form factor should be chosen based on the specific application requirements.

At JHYPCB, we have experience in designing and manufacturing PCBs for various industrial automation and control applications. Our engineers work closely with customers to ensure that their PCB designs meet all the required specifications. We use advanced design tools and simulation software to optimize the design and ensure optimal performance and reliability of the PCBs.

Get Competitive Pricing and Exceptional Quality on Your PCB Needs for Industrial Automation and Control Systems!

PCB assembly for industrial automation and control

PCB assembly is a critical process in the manufacturing of PCBs for industrial automation and control systems. The following are the key considerations for PCB assembly:

Component selection: It is important to choose components that are suitable for the specific application requirements, including operating temperature, power requirements, and signal frequency.

SMT vs. Through-hole assembly: Surface-mount technology (SMT) and through-hole assembly are two common methods used in PCB assembly. SMT is generally faster and more cost-effective, while through-hole assembly offers better mechanical strength and reliability. The choice of assembly method depends on the specific requirements of the application.

Quality control: PCB assembly requires strict quality control measures to ensure that all components are properly placed, soldered, and tested. Automated optical inspection (AOI) and X-ray inspection are commonly used to detect any defects or errors in the assembly process.

Testing and verification: Once the PCB assembly is complete, it undergoes various testing and verification processes to ensure that it meets the required specifications. This includes functional testing, in-circuit testing, and boundary scan testing.

Traceability and documentation: It is important to maintain accurate records of the PCB assembly process, including component sourcing, testing results, and any modifications made to the design. This helps ensure traceability and makes it easier to diagnose and correct any issues that arise during operation.

At JHYPCB, we follow strict quality control measures throughout the PCB assembly process. We use advanced equipment and software to ensure accurate component placement and soldering. Our engineers perform comprehensive testing and verification to ensure that all PCBs meet the required specifications. We also maintain detailed records of the assembly process to ensure traceability and facilitate any necessary repairs or modifications.

Applications of PCBs in industrial automation and control

PCBs have a wide range of applications in industrial automation and control systems. The following are some of the most common applications of PCBs in this field:

Sensor control and data acquisition: PCBs are used to interface with sensors and collect data on various process parameters such as temperature, pressure, and flow rate. This data is then transmitted to a controller for analysis and decision-making.

Temperature and humidity control: PCBs are used to regulate temperature and humidity levels in industrial environments. They control heating and cooling systems, humidifiers, and dehumidifiers to maintain optimal working conditions.

Production line monitoring and control: PCBs are used to monitor and control production lines in manufacturing facilities. They control conveyor belts, motors, and other machinery to ensure efficient and safe operation.

Motor control and power electronics: PCBs are used to control motors and other power electronics in industrial equipment such as pumps, fans, and compressors. They regulate voltage and current to ensure optimal performance and energy efficiency.

Human-machine interface (HMI): PCBs are used to interface with human operators in industrial settings. They provide feedback on system status, allow for user input, and enable remote control of equipment.

Communication and networking: PCBs are used to facilitate communication and networking between various industrial automation and control systems. They provide interfaces for Ethernet, CAN bus, Modbus, and other communication protocols.

At JHYPCB, we have experience in manufacturing PCBs for all of these applications and more. Our team works closely with customers to understand their specific requirements and design custom PCBs that meet their needs. We use advanced equipment and software to ensure the highest quality in the design, fabrication, assembly, and testing of our PCBs.

How JHYPCB can meet your PCB manufacturing needs

JHYPCB is a leading manufacturer of PCBs for industrial automation and control systems. We offer a range of services to meet all your PCB manufacturing needs:

PCB design: Our team of experienced engineers can help you with all aspects of PCB design, including schematic capture, layout, and optimization for specific applications.

PCB fabrication: We use advanced equipment and processes to fabricate high-quality PCBs that meet your exact specifications. Our capabilities include drilling, plating, etching, and more.

PCB assembly: We offer both SMT and through-hole assembly services, as well as other value-added services such as testing, programming, and packaging.

Quality control: We have strict quality control measures in place throughout the PCB manufacturing process to ensure that every PCB meets the required specifications. We use automated optical inspection (AOI) and X-ray inspection to detect any defects or errors in the PCBs.

Customer service: We are committed to providing the highest level of customer service to our clients. Our team is available to answer questions and provide support at every stage of the PCB manufacturing process.

Competitive pricing: We offer competitive pricing for our PCB manufacturing services without compromising on quality or reliability.

At JHYPCB, we pride ourselves on delivering high-quality PCB products and services that meet the needs of our customers in the industrial automation and control industry. With years of experience in PCB manufacturing and state-of-the-art equipment and processes, we are confident that we can meet your PCB manufacturing needs and exceed your expectations.