PCB Electronic Manufacturing Services

PCB For Medical Device

Choose JHYPCB for high-quality medical device PCB manufacturing and assembly services. Our services meet FDA and CE requirements, and our engineers provide technical support and advice to help you achieve optimal product performance.

Reliable and High-Quality Medical Device PCB Manufacturing and Assembly Services by JHYPCB

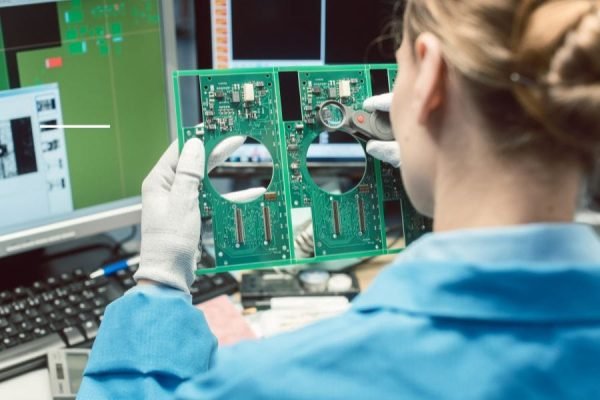

Expert Medical Device PCB Manufacturer

JHYPCB is a reliable and experienced manufacturer and assembler of medical device PCBs. Our advanced technology and equipment, combined with our commitment to rigorous quality control, ensure that our products meet the highest safety, reliability, and precision standards needed for the medical industry. At JHYPCB, we understand the unique demands and challenges of medical device PCBs and are dedicated to providing customized solutions that meet your specific needs. Our engineers provide expert technical support and advice throughout the design and production process to ensure that your products perform at their best.

Medical Device Industry Printed Circuit Board

Applications for Medical Device PCBs

Medical device Printed Circuit Boards are an essential component of various medical equipment. They provide high-level functionality and automation to healthcare systems and help in improving both diagnosis and treatment accuracy. Here are some of the common applications of medical device PCBs:

Medical imaging systems

PCBs are used in various medical imaging systems such as Magnetic Resonance Imaging (MRI), Computed Tomography (CT), Positron Emission Tomography (PET), and X-ray machines. They enable the transfer of digital signals from the sensors to the image processing unit, resulting in high-resolution images.

Surgical instruments control

PCBs are an integral part of surgical instruments that are used in minimally invasive surgeries (MIS) and robotic-assisted surgeries (RAS). They allow precise control of tools and instruments, which leads to fewer complications and faster recovery times for patients.

Life support systems

Medical device PCBs also power life support systems such as artificial hearts, pacemakers, and ventilators. These devices require high reliability, precision, and accuracy to ensure patient safety, making PCBs critical components.

Monitoring devices

PCBs are extensively used in monitoring devices such as blood pressure monitors, glucose meters, and electrocardiogram (ECG) machines. Medical device PCBs measure, analyze, and transmit data to healthcare providers, enabling them to make accurate diagnoses and provide personalized treatment options.

Wearable medical devices

With advances in technology, wearable medical devices have become increasingly popular. These devices are used for remote patient monitoring, sleep tracking, and fitness tracking. Medical device PCBs provide reliable and accurate data collection, analysis, and wireless connectivity for these devices, making them more effective health management tools.

Laboratory and diagnostic equipment

Medical device PCBs also play a crucial role in laboratory and diagnostic equipment such as microscopes, DNA sequencers, and mass spectrometers. These devices require high-precision control systems to manipulate samples or detect biomolecules accurately, which makes PCBs an essential component.

Types of Medical Device PCB

There are various types of medical PCBs available, each designed to meet specific application requirements. Let’s take a closer look at some of the different types of medical PCBs.

Rigid PCBs: Rigid PCBs are the most common type of PCB used in medical devices. They are made from a rigid substrate, such as FR-4 or polyimide, and are suitable for applications that require high mechanical strength and durability.

Flexible PCBs: Flexible PCBs are made from a flexible substrate, such as polyimide or polyester, and are ideal for applications that require flexibility and adaptability. They are commonly used in wearable medical devices and implantable medical devices.

High-Density Interconnect (HDI) PCBs: HDI PCBs are designed for applications that require high-density interconnections, such as implantable medical devices and portable medical equipment. They have smaller vias, pads, and traces, which allow for more compact designs.

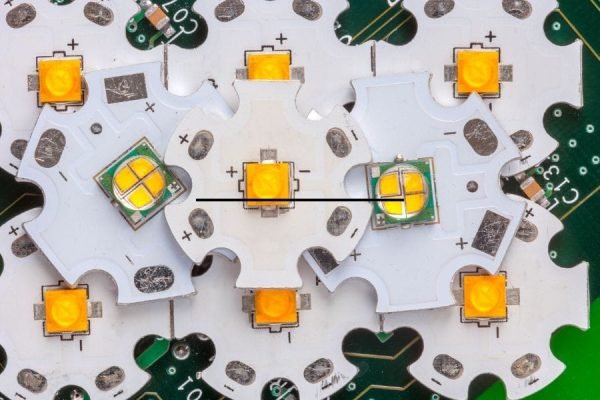

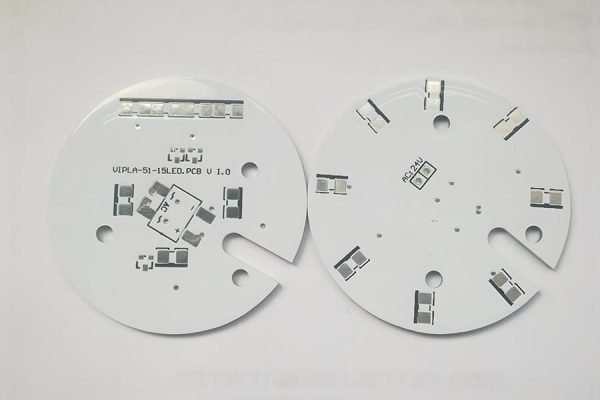

Metal Core PCBs: Metal Core PCBs, also known as thermal PCBs, are designed to dissipate heat more efficiently than standard PCBs. They are commonly used in medical equipment that generates heat, such as ultrasound machines and laser surgery devices.

Ceramic PCBs: Ceramic PCBs are made from a ceramic material that offers excellent thermal conductivity and electrical insulation properties. They are commonly used in medical equipment that requires high-temperature resistance, such as MRI machines.

Flex-rigid PCBs: Flex-rigid PCBs are a combination of flexible and rigid PCBs, offering the benefits of both. They provide flexibility and adaptability in certain areas of the PCB, while maintaining rigidity and stability in other areas. They are commonly used in complex medical devices that require multiple functionalities.

RF/Microwave PCBs: RF/Microwave PCBs are designed to work at high frequencies and are widely used in medical applications such as wireless communication systems, remote monitoring devices, and signal processing equipment.

Backplane PCBs: Backplane PCBs are designed to connect multiple PCBs together to form a complete system. They are commonly used in larger medical systems that require multiple PCBs to function together, such as CT scanners or X-ray machines.

Choosing the right type of medical PCB is crucial for ensuring that the medical device functions safely and accurately. The choice of PCB depends on the specific requirements of the application, such as thermal management, flexibility, rigidity, frequency, and connectivity. At JHYPCB, we offer a wide range of Medical PCB manufacturing services to meet your unique needs.

Medical Device PCB Challenge

special requirements for medical device PCBs

Medical device PCBs are an integral part of various medical equipment and devices. However, due to the critical nature of these devices and their potential impact on patient health, medical device PCBs must meet specific safety, reliability, and performance requirements. Here are some of the critical requirements for medical device PCBs:

Medical device PCBs must meet strict safety standards to ensure that they do not endanger the lives of patients or healthcare providers. These standards cover aspects such as electromagnetic interference (EMI) and radiofrequency interference (RFI), electrical insulation, and protection against shocks and fires.

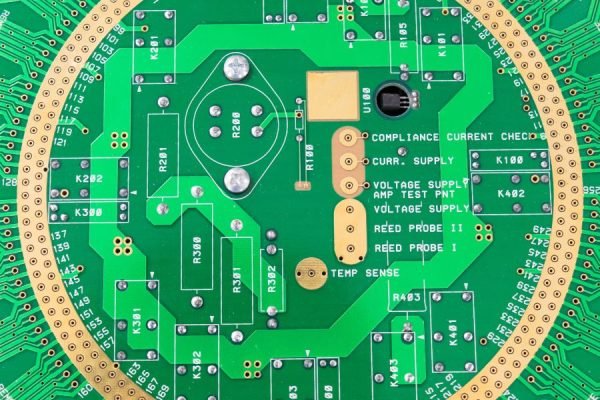

Medical device PCBs require high precision and accuracy to ensure that they provide reliable performance. Even small errors or inaccuracies can have severe consequences in a medical setting. Additionally, medical device PCBs must be designed and manufactured to be highly reliable and durable, even under harsh conditions.

Because medical device PCBs are often exposed to harsh chemicals and sterilization processes, they must be resistant to corrosion and have antibacterial properties so that they do not become breeding grounds for harmful bacteria.

Medical device PCBs must comply with regulatory requirements set by organizations such as the Food and Drug Administration (FDA) and the European Union’s Conformité Européene (CE) mark. These regulatory bodies ensure that medical equipment and devices are safe, effective, and reliable.

Medical device PCBs have specific requirements that must be met to ensure that they are safe, reliable, and effective. Meeting these requirements requires an experienced and knowledgeable team with advanced technology and equipment. Choosing a trusted and experienced medical device PCB manufacturer like JHYPCB ensures that your devices meet these requirements and provide high-quality performance.

Ensuring Compliance, Reliability, and Performance

Medical device PCBs are critical components in medical equipment and devices that require high levels of safety and reliability. These devices undergo rigorous testing to ensure that they meet specific safety standards and regulations. Here are some common safety tests and certifications for medical device PCBs:

EMC testing: Electromagnetic compatibility (EMC) testing ensures that the PCBs do not emit electromagnetic interference that could affect the performance of other medical equipment. Additionally, it also ensures that the PCBs are not affected by electromagnetic interference from other devices.

Reliability testing: Medical device PCBs must be highly reliable to ensure that they perform safely and accurately over extended periods. Reliability testing includes environmental stress testing, accelerated life testing, and other tests to verify the longevity and durability of the PCBs.

UL, RoHS, and other certifications: Medical device PCBs must comply with various international standards and regulations, such as Underwriters Laboratories (UL) and the Restriction of Hazardous Substances (RoHS) directive. These certifications ensure that the PCBs meet safety, health, and environmental protection requirements.

FDA and CE certifications: To sell medical devices and equipment in the US and EU markets, medical device PCBs must comply with the regulations set by the Food and Drug Administration (FDA) and the European Union’s Conformité Européene (CE) mark. These certifications ensure that the medical device PCBs are safe, effective, and reliable for use in medical applications.

JHYPCB's professional services

JHYPCB is a leading provider of medical device PCB manufacturing and assembly services. With our extensive experience in the industry and advanced technology and equipment, we offer customized solutions to meet the specific needs of our clients. Here are some of the professional services we offer:

Advanced PCB technology: Our state-of-the-art equipment allows us to produce high-quality and technologically advanced PCBs for medical devices. We offer various types of PCBs, including rigid, flexible, and rigid-flex PCBs, and can deliver customized solutions to meet your requirements.

Full-service assembly: We provide comprehensive assembly services, including surface-mount technology (SMT), through-hole technology (THT), and mixed technology. Our experts handle every aspect of the assembly process, from component sourcing and PCB fabrication to final testing.

Technical support and advice: Our team of experienced engineers provides expert technical support and advice throughout the design and production process to ensure that your products perform at their best. We help optimize your designs for manufacturability, troubleshoot design issues, and suggest improvements to enhance product functionality.

Quality control: We have a rigorous quality control system in place to ensure that our products meet the highest safety, reliability, and precision standards needed for the medical industry. We conduct various tests, such as visual inspection, functional testing, and burn-in testing, to verify product quality.

At JHYPCB, we are committed to providing our clients with the best possible service, ensuring compliance with regulations, and delivering high-quality PCBs that meet their unique requirements.

Get a Quick Quote

Experience the professional services of JHYPCB for your medical device PCB needs. Contact us today at sales@pcbjhy.com or fill out our online inquiry form to get in touch with our experts and receive a quote tailored to your project requirements.

FAQs

What is a medical device PCB?

A medical device PCB is a printed circuit board that is used in medical equipment and devices. These PCBs must meet specific safety, reliability, and performance requirements.

What are the common applications of medical device PCBs?

Medical device PCBs are used in various medical equipment and devices, such as imaging systems, surgical instruments, life support systems, monitoring devices, and wearable medical devices, among others.

What are the special requirements for medical device PCBs?

Medical device PCBs have specific requirements, including safety, high precision and reliability, corrosion resistance, antibacterial properties, and compliance with FDA, CE, and other regulations.

How are medical device PCBs tested for safety?

Medical device PCBs undergo rigorous testing, including EMC testing, reliability testing, and other tests to verify compliance with international standards and regulations.

What certifications are required for medical device PCBs?

Medical device PCBs require various certifications, such as UL, RoHS, FDA, and CE, to ensure safety, health, and environmental protection, and to comply with international regulations.

How can I ensure that my medical device PCBs meet the required safety and quality standards?

To ensure that your medical device PCBs meet the required safety and quality standards, it is essential to partner with an experienced and knowledgeable manufacturer like JHYPCB. Our team of experts will guide you through the design and production process and provide tailored solutions to meet your specific requirements.

How can I request a quote or get in touch with JHYPCB?

You can contact JHYPCB by emailing us at sales@pcbjhy.com, filling out our online inquiry form, or calling us directly. Our experts are always available to answer any questions you may have and provide you with a quote tailored to your project requirements.

What materials are used to manufacture medical device PCBs?

Medical device PCBs are made from high-quality materials, such as FR-4, polyimide, and Rogers, to ensure that they meet the required safety and performance standards.

How long does it take to manufacture medical device PCBs?

The time it takes to manufacture medical device PCBs depends on various factors, such as the complexity of the design, the type of PCB, and the quantity required. At JHYPCB, we offer fast turnaround times and can provide you with an estimated lead time for your project.

What is the price range for medical device PCBs?

The price of medical device PCBs varies depending on several factors, such as the complexity of the design, the type of PCB, and the quantity required. At JHYPCB, we offer competitive pricing and will provide you with a quote tailored to your project requirements.

How do I ensure the confidentiality of my design files?

At JHYPCB, we take data security and confidentiality very seriously. We have strict protocols in place to protect our clients' intellectual property and use secure file transfer protocols to ensure the safe transfer of design files.