PCB Electronic Manufacturing Services

Printed Circuit Boards for Marine Applications

JHYPCB specializes in the manufacturing, and assembly of printed circuit boards for marine applications. From prototyping to production, our expert team is here to help you bring your project to life.

Marine PCB Manufacturer

Your Partner for Marine Printed Circuit Boards

If you are involved in the marine industry, whether it is servicing or planning to enter this field, you must understand the essential role that printed circuit boards play in various marine electronics and applications. In the marine industry, electronic PCBs must be able to operate reliably and stably in harsh environments, withstanding harsh weather conditions, high humidity, saltwater corrosion, and physical impact. Proper PCB design is critical for marine industry applications, as PCBs used in marine electronics require unique electronic connectivity and mechanical support to withstand these harsh conditions.

At JHYPCB, we understand the importance of providing high-quality PCBs that meet the unique needs of the marine industry. We have served many customers through years of experience in PCB manufacturing and assembly.

Our goal at JHYPCB is to provide the marine industry with reliable, long-lasting, and high-performing PCB. Through our commitment to excellence and technological leadership, we have established ourselves as a trusted and preferred partner for many marine companies. Whether you need a prototype or mass production, we have the expertise, experience, and technology to deliver PCBs that meet your specific requirements.

What types of marine vessels make use of marine PCBs?

Marine industry PCBs are used in a wide variety of vessels, including but not limited to:

- Cruise ships

- Cargo ships

- Tankers

- Fishing vessels

- Luxury yachts

- Military vessels

- Offshore oil rigs

- Research vessels

- Ferries

- Tugboats

These vessels rely on electronic devices for communication, navigation, and other crucial operations, and these electronic systems rely on marine industry PCBs to provide reliable and high-performance connectivity. These PCBs have become increasingly important in the marine industry as the demand for more advanced and complex electronic components has grown. These PCBs must withstand harsh marine environments, including saltwater exposure, extreme temperatures, and high vibration levels. Therefore, choosing a reliable PCB manufacturer that can provide high-quality products that meet the rigorous demands of marine applications is important.

5 Types of Maritime Electronic Devices That Rely on PCBs

There are several types of maritime electronic devices that rely on printed circuit boards, including:

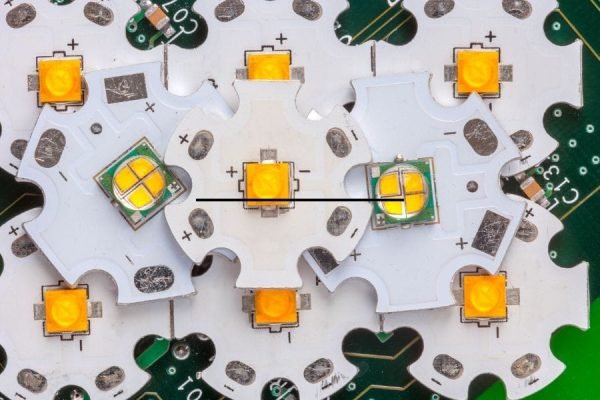

1. Navigation equipment: This includes navigational instruments such as GPS receivers, radar antennas, and sonar transducers. These devices require precise PCB designs to ensure accurate performance.

2. Communication equipment: Maritime communication systems use a variety of electronic devices, including radios, modems, and data links. These devices require PCBs to house the various components and connect them together.

3. Engine control systems: Marine engines rely on complex electronic control systems to manage fuel injection, ignition timing, and other critical functions. These systems typically include PCBs for power distribution and signal processing.

4. Instrument panels: Marine instrument panels contain a variety of electronic displays and controls, including speedometers, tachometers, and engine monitors. These panels require PCBs to house the display and control logic.

5. Safety equipment: Maritime safety equipment such as fire alarms, lifeboat switches, and smoke detectors all rely on PCBs to function correctly. These devices must meet strict safety standards and be designed for durability in harsh marine environments.

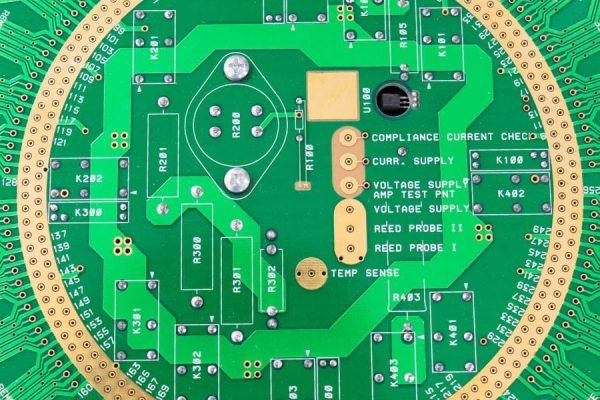

PCB Design Guide for Marine Applications

Designing printed circuit boards for marine applications requires careful attention to the unique challenges of the marine environment. One of the primary concerns is ensuring that the boards are waterproof and resistant to corrosion. This is typically achieved through the use of specialized coatings or materials, such as conformal coatings, polymer thick film coatings, or solder mask coatings.

Another important consideration in marine PCB design is heat dissipation. Because marine vessels are often exposed to high temperatures, it’s important to design boards with proper thermal management. This can be achieved through the use of heat sinks, thermal vias or conductive pads.

Another important factor in marine PCB design is vibration resistance. Marine vessels are constantly exposed to vibrations from the ocean and from the vessel’s engines and machinery. This can cause damage to unprotected circuit boards. To mitigate this, PCBs for marine applications can be designed with extra mounting holes, stiffeners, or other supports.

Finally, it’s important to consider the power requirements of marine electronic devices. In marine environments, power supplies can be less stable or more prone to interference than they are on land. PCB designers need to make sure that their boards are optimized for the real-world constraints of marine application power requirements. This can involve careful layout planning, ground plane decisions, and component choices.

JHYPCB's PCB Manufacturing and Assembly Services

JHYPCB offers PCB manufacturing and assembly services specifically designed for marine applications. Our experienced engineers work closely with customers to ensure that each order is manufactured to the highest standards, meeting industry requirements, and regulations.

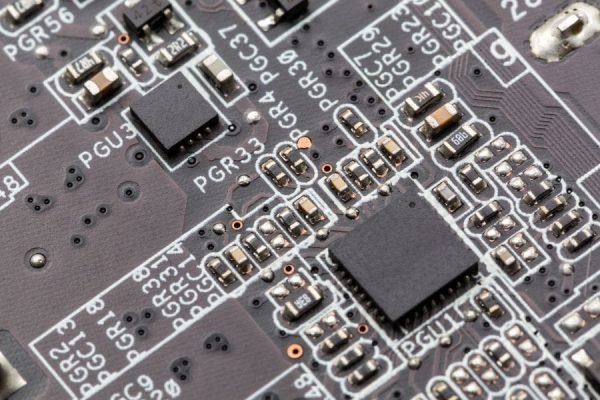

Our PCB fabrication services include fast turnaround time, ensuring that orders are processed quickly and efficiently. Our PCB manufacturing service includes multilayer PCB, HDI PCB, flexible PCB, rigid-flex PCB, high-frequency PCB, etc. We use high-quality materials and coatings to ensure our PCBs are waterproof, corrosion-resistant, and durable in harsh marine environments.

In addition to manufacturing, JHYPCB also offers PCB assembly services for marine applications. Our advanced SMT and THT technologies ensure reliable connections and efficient assembly, while our strict quality management system ensures that each product meets industry standards and regulations.