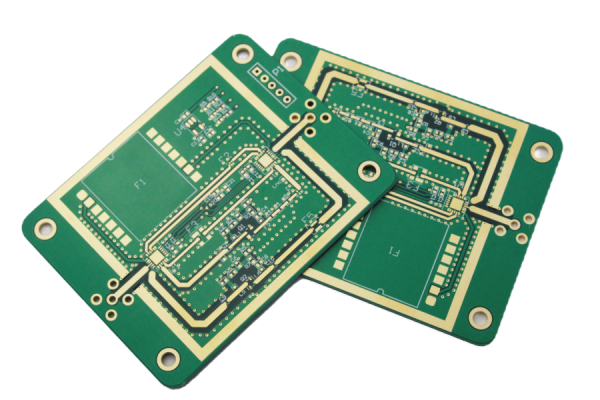

Impedance Control PCB Fabrication Service

What IS Impedance Control PCB?

Impedance control PCBs play an important role in modern electronics manufacturing. They are designed to control the electrical impedance of the circuit, which is crucial for high-speed digital, high-frequency analog, and RF circuits.

JHYPCB

What is Impedance?

Impedance is a measure of the opposition of a circuit to the flow of electrical current when a voltage is applied. It is represented by the symbol “Z” and is measured in ohms (Ω). Impedance takes into account both resistance and reactance, which is the opposition to current flow caused by capacitive and inductive effects in a circuit.

In a circuit with purely resistive elements, such as a simple light bulb, the impedance is equal to the resistance. However, in circuits with capacitors, inductors, or a combination of both, the impedance is a complex quantity that depends on the frequency of the applied voltage.

Impedance is an important concept in electrical engineering and plays a critical role in the design and analysis of circuits. In particular, impedance control is essential in high-speed digital, high-frequency analog, and RF circuits to ensure signal integrity and minimize noise and interference.

What is Impedance Control PCB?

Impedance control PCB (Printed Circuit Board) is a type of PCB that is designed and manufactured to achieve precise and consistent electrical impedance throughout the circuit. Impedance control PCBs are important for high-speed digital, high-frequency analog, and RF (Radio Frequency) circuits where signal integrity is critical.

Impedance control PCBs are designed to match the impedance of the signal traces to the impedance of the devices or components that are connected to them. This matching ensures that the signal is transmitted with minimal distortion, reflection, or interference. Impedance control PCBs typically use specialized materials and manufacturing processes to achieve the desired impedance characteristics, including precise control of trace widths, spacing, and dielectric constant.

Impedance control PCBs are commonly used in communication systems, such as cellular networks, satellite communications, and high-speed data transmission applications. They are also used in other applications where high-speed and high-frequency signals require precise impedance control, such as in medical devices, automotive systems, and aerospace technology.

Proper design, manufacturing, testing, and maintenance of impedance control PCBs are essential to ensure optimal performance and reliability. Impedance mismatches or other signal integrity issues can cause significant problems in high-speed or high-frequency circuits, leading to data errors, system malfunctions, or even total failure.

Why control impedance on PCBs?

Controlling impedance on PCBs is important for maintaining signal integrity and minimizing noise and interference in high-speed digital, high-frequency analog, and RF circuits. Impedance control ensures that the impedance of the signal traces matches the impedance of the devices or components that are connected to them. This matching ensures that the signal is transmitted with minimal distortion, reflection, or interference.

In high-speed digital circuits, impedance control helps to prevent signal reflections, which can cause data errors, signal jitter, or other performance issues. In high-frequency analog circuits, impedance control is critical for maintaining a stable, accurate signal, and for minimizing noise and interference. In RF circuits, impedance control is essential for maximizing signal strength, minimizing loss, and maintaining a consistent signal over a range of frequencies.

Controlling impedance on PCBs requires careful consideration of the circuit design, the materials used, and the manufacturing processes. Proper design and manufacturing techniques, including precise control of trace widths, spacing, and dielectric constant, are necessary to achieve the desired impedance characteristics.

Overall, impedance control is a crucial factor in the performance and reliability of high-speed digital, high-frequency analog, and RF circuits. Proper impedance control on PCBs helps to ensure that these circuits function as intended, with minimal distortion, noise, or interference.

What are some of the factors affecting impedance?

There are several factors that can affect the impedance of a circuit on a PCB. Understanding these factors is crucial to achieving precise and consistent impedance control on high-speed digital, high-frequency analog, and RF circuits. They are include Trace Width and Thickness, Dielectric Constant, Distance between Traces, Via Placement, Temperature, Frequency, etc. Careful consideration of these factors is crucial to achieving precise and consistent impedance control on high-speed digital, high-frequency analog, and RF circuits. Proper design and manufacturing techniques are necessary to control these factors and achieve the desired impedance characteristics.

Impedance Control PCB Applications

Impedance control PCBs are used in a wide range of applications, including high-speed digital circuits, high-frequency analog circuits, RF circuits, control systems, and power management systems. They are particularly important in communication systems, such as cellular networks and satellite communications, where high-speed and high-frequency signals require precise impedance control.

Impedance Control PCB Manufacturer

As a leading PCB manufacturer, we specialize in providing high-quality impedance control PCBs for a wide range of applications. Our state-of-the-art facilities and experienced team of engineers are equipped to deliver reliable, precise, and cost-effective impedance control PCB prototypes and volume manufacturing services.

We pride ourselves on our ability to deliver customized solutions tailored to meet the specific needs of our clients. Whether you need a few prototypes for testing or large-scale production runs, we can provide fast turnaround times and competitive pricing without sacrificing quality or performance.

If you’re looking for a reliable partner for your impedance control PCB needs, look no further than our team at JHYPCB. Contact us today to learn more about our services and how we can help you achieve your PCB manufacturing goals.