Scalable Electronics Manufacturing

High Volume PCB Assembly Service

Efficient, reliable, and cost-effective PCB assembly solutions for your large-scale production needs

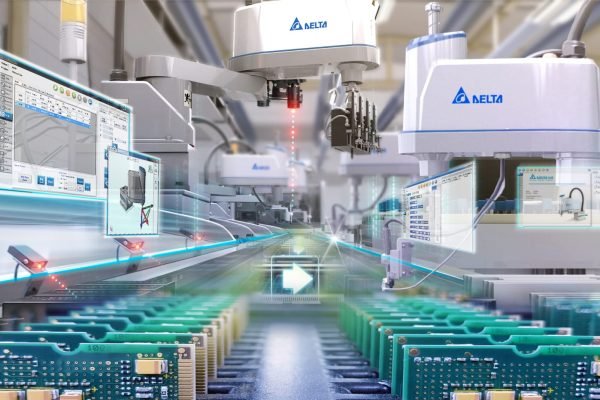

Streamline Your Large-Scale Production with JHYPCB

Welcome to JHYPCB’s high volume PCB assembly service. As a leading Chinese PCB manufacturer and assembly provider, we specialize in delivering efficient, cost-effective solutions for your large-scale electronics production needs. Our state-of-the-art facilities and experienced team are equipped to handle high-volume orders with precision and speed, ensuring top-quality results for your PCB projects.

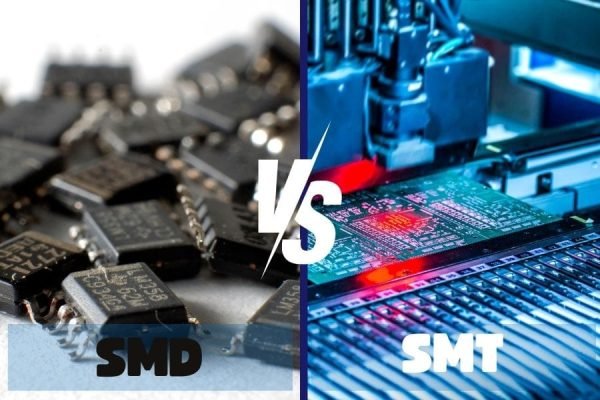

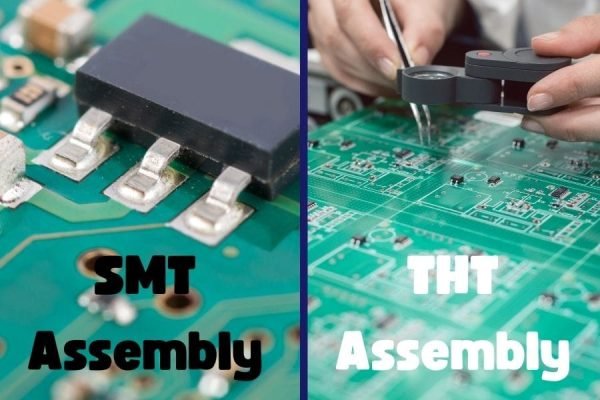

At JHYPCB, we combine advanced SMT and THT technologies with streamlined processes to offer:

- Rapid turnaround times

- Competitive pricing

- Consistent quality across large batches

- Flexible production capacity

Whether you’re in consumer electronics, automotive, industrial equipment, or any other sector requiring high-volume PCB assembly, JHYPCB is your trusted partner for scalable, reliable manufacturing solutions.

Why Choose JHYPCB for High Volume PCB Assembly?

At JHYPCB, we understand that high volume PCB assembly requires a perfect balance of speed, quality, and cost-effectiveness. Our service is designed to meet these demands, providing you with a competitive edge in today’s fast-paced electronics market. Here’s why leading companies trust us with their large-scale PCB assembly needs:

Rapid Production

Fast turnaround without compromising quality.

Our optimized processes and advanced equipment ensure quick delivery of large orders.

Cost-Effective Solutions

Competitive pricing for high volume orders.

Benefit from economies of scale and our efficient operations to reduce your production costs.

Stringent Quality Control

Consistent quality across large batches.

Our rigorous quality assurance procedures guarantee reliability in every PCB we assemble.

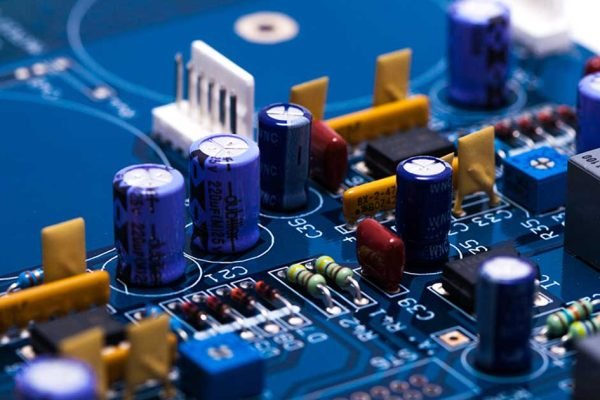

Advanced Technology

State-of-the-art SMT and THT capabilities.

We employ the latest assembly technologies to handle complex designs and high-density boards.

Supply Chain Expertise

Efficient component sourcing and management.

Our established relationships with suppliers ensure smooth, uninterrupted production.

Flexible Capacity

Scalable production to meet your needs.

Whether you need thousands or millions of PCBs, we can adjust our capacity to match your requirements.

Our High Volume PCB Assembly Process

At JHYPCB, we’ve refined our high volume PCB assembly process to ensure efficiency, quality, and scalability. Our streamlined workflow allows us to handle large orders with precision and speed, delivering consistent results for every project.

Step 1

Design for Manufacturing (DFM) Review

Our engineering team carefully reviews your PCB design, suggesting optimizations to enhance manufacturability and yield for high-volume production. This step ensures smooth assembly and reduces potential issues.

Step 2

Component Procurement

Leveraging our extensive supplier network, we source high-quality components at competitive prices. Our efficient inventory management ensures all necessary parts are available for your large-scale production runs.

Step 3

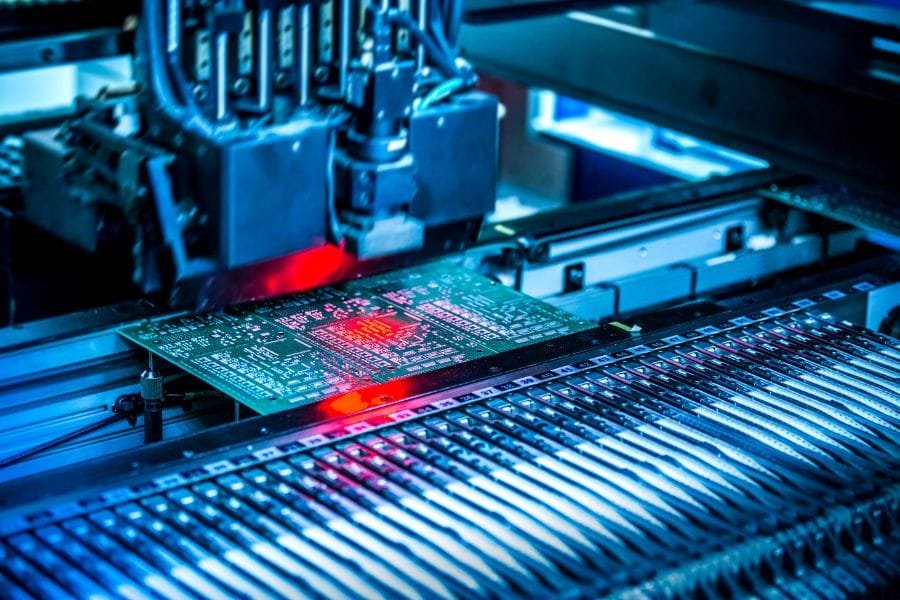

SMT and THT Assembly

Using state-of-the-art pick-and-place machines and soldering equipment, we precisely assemble your PCBs. Our advanced SMT lines handle high-speed placement of even the smallest components, while our skilled technicians manage THT assembly for through-hole parts.

Step 4

Quality Control and Testing

Every PCB undergoes thorough inspection and testing, including AOI (Automated Optical Inspection), X-ray inspection for hidden solder joints, and functional testing. This multi-stage QC process guarantees consistent quality across large batches.

Step 5

Packaging and Shipping

We carefully package your assembled PCBs to protect them during transit. Our logistics team ensures timely and secure delivery of your order, whether it’s a local shipment or international freight.

Advanced Equipment and Technology

At JHYPCB, we invest in cutting-edge technology to ensure top-quality high volume PCB assembly. Our state-of-the-art equipment allows us to handle complex designs, maintain high precision, and achieve rapid production speeds.

SMT Pick and Place Machine

High-speed, high-precision component placement for efficient large-scale production.

AOI System

Advanced defect detection for consistent quality across large batches.

Flying Probe Testing

Flying probe testing is usually used in small-scale production for development purposes.

Reflow Oven

Precise temperature control for optimal solder joint quality in high-volume PCB assembly.

X-ray Inspection System

Inspects hidden solder joints and BGA components for thorough quality assurance.

First Article Inspection

FAI is performed during PCBA to ensure compliance with specifications and quality.

ICT

ICT (In-Circuit Test), with high testing efficiency, is usually used on high-volume PCB assembly.

Wave soldering

The method for soldering through-hole components onto PCBs.

FCT

FCT functional testing is usually used on some complex circuit boards.

Industries We Serve

JHYPCB’s high volume PCB assembly services cater to a wide range of industries, providing tailored solutions for diverse applications and requirements.

Industrial Electronics

Robust PCB solutions for demanding industrial environments

Medical Devices

Precision assembly for life-critical medical equipment

Automotive

High-reliability assemblies for modern vehicle electronics

Renewable Energy

Durable PCBs for solar inverters and energy management systems

Consumer Electronics

Efficient production for high-volume consumer devices

Telecommunications

High-performance assemblies for networking and communication devices

With years of experience across these diverse sectors, JHYPCB has developed the expertise to meet the unique challenges of each industry. Our adaptable high volume PCB assembly services ensure that whether you’re producing smart home devices or industrial control systems, you receive top-quality results tailored to your specific needs.

Why Choose JHYPCB for High Volume PCB Assembly

When it comes to high volume PCB assembly, JHYPCB stands out as your ideal partner. Our commitment to quality, efficiency, and customer satisfaction sets us apart in the industry. Here’s why leading companies trust us with their large-scale PCB assembly needs:

Proven Track Record

Over 15 years of experience in high-volume PCB assembly, serving 3000+ satisfied clients worldwide.

Rapid Turnaround

Industry-leading production speeds without compromising on quality. 99% on-time delivery rate.

Technical Expertise

Skilled engineers and technicians with deep knowledge in PCB assembly and the latest industry trends.

Global Supply Chain

Strategic partnerships with component suppliers ensure stable supply and competitive pricing for your projects.

Quality Assurance

Rigorous quality control processes, including AOI and X-ray inspection, guaranteeing 100% defect-free rate.

Customer-Centric Approach

Dedicated account managers and responsive support team to ensure your project’s success.

At JHYPCB, we don’t just assemble PCBs; we build lasting partnerships. Our commitment to excellence, combined with our state-of-the-art facilities and customer-focused approach, makes us the preferred choice for high volume PCB assembly. Whether you’re scaling up production or launching a new product line, JHYPCB has the expertise and capacity to meet your needs.