Here at JHYPCB, we specialize in providing fast PCB prototypes to help hardware engineers and designers test their concepts quickly. One of the options we offer is double-sided PCBs, which have many benefits for prototyping purposes over single-sided boards.

In this blog post, we’ll explain what double-sided PCBs are and why they can be advantageous when you need to build an initial prototype board.

What Are Double Sided PCBs?

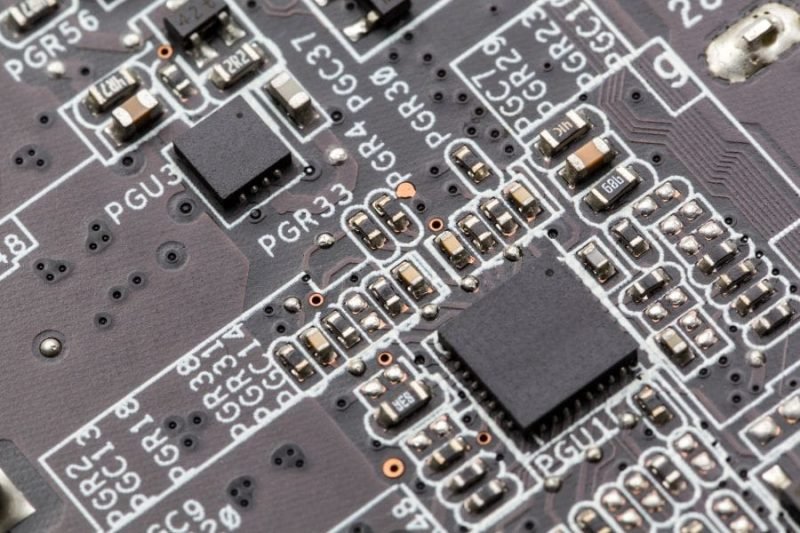

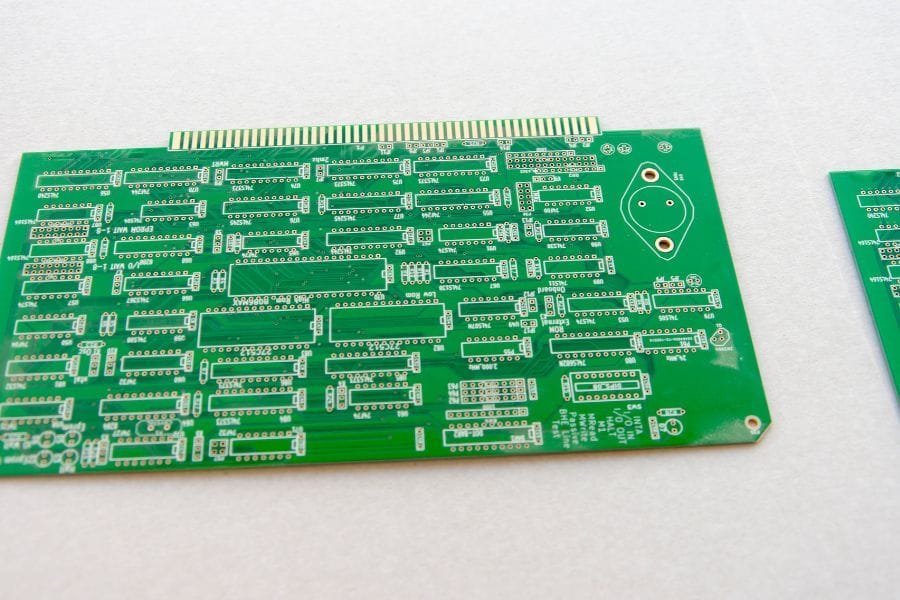

A double sided PCB has conductive copper layers on both the top and bottom surface of the board. This allows components and traces to be placed on both sides. Through-hole components and vias make electrical connections between the top and bottom layers.

In contrast, single-sided PCBs only have a copper layer on one side of the board. All components and traces are on that one surface only.

Related Reading: Types of PCBs: Comprehensive Guide to Printed Circuit Boards

Space and Layout Advantages

The key benefit of double sided PCBs is the increased space and more optimized layout opportunities they provide. With the ability to place components and routing on both sides, you can fit more into a given board area.

This helps when you need to prototype complicated circuit designs but want to keep the board at a reasonably small size for testing. You have more flexibility to route traces efficiently while still grouping related components together.

Lower Layer Count for Complex Circuits

Some prototypes might otherwise require four, six, or more layers if limited to a single-sided board. However, using both the top and bottom surfaces creatively in a double sided layout can allow achieving similar complexity with only two layers instead.

This helps reduce costs and lead times for your prototype boards. We deliver high-quality double-sided boards with a rapid turnaround.

JHYPCB's Capabilities

Here at JHYPCB, we provide a range of rapid prototyping PCB services to help hardware innovators. In addition to standard, single-sided, and double-sided boards, capabilities like:

- SMT assembly

- Per board quantities starting at just 5 boards

- 2 day average lead times for double-sided PCBs

- FR4, Rogers, Isola laminates options

- Impedance control PCBs

- 2 oz copper boards

- ENIG surface finish available

Contact us today to learn more about our double sided PCB capabilities – ideal for reducing prototyping costs and board size while testing your newest electronic devices. Our engineering support team is also happy to discuss advanced layout considerations to optimize your specific design. Reach out with any questions!