Introduction

Polyester (PET) and polyimide (PI) are two common materials used in the manufacturing of flexible printed circuit boards (flex PCBs). Flex PCBs are widely used in various electronic devices, from mobile phones and laptops to medical equipment and aerospace technology. PET and PI offer different physical and chemical properties that make them suitable for specific applications in flex PCBs. This blog post will explore the differences between PET and PI materials, including their physical and chemical properties, applications in flex PCBs, manufacturing processes, and environmental impact. By understanding the unique characteristics of PET and PI, you can make informed decisions about which material is best suited for your specific flex PCB needs.

PET material: PET, or polyethylene terephthalate, is a type of thermoplastic polymer that is widely used in various industrial and consumer applications, including the production of textiles, packaging materials, and electronic components. PET is known for its high strength, stiffness, durability, and resistance to moisture, chemicals, and UV radiation. It is also a recyclable material, which makes it a popular choice for sustainable packaging solutions.

PI material: PI, or polyimide, is a high-performance polymer known for its exceptional heat resistance, mechanical strength, and electrical insulation properties. PI is often used in high-temperature applications, such as aerospace, automotive, and electronics industries, where its ability to withstand extreme temperatures and harsh environments is critical. PI is also a lightweight and flexible material, which makes it ideal for use in flexible circuits and other applications where space and weight are at a premium.

Physical Properties

The physical properties of materials play a critical role in determining their suitability for specific applications. Regarding flexible printed circuit boards, the choice of materials can impact the board’s mechanical, electrical, and thermal performance. This section will explore the physical properties of two common materials used in flex PCBs: polyester and polyamide. By understanding the unique physical properties of these materials, you can make informed decisions about which material is best suited for your specific flex PCB needs.

A. Physical properties of PET:

- Density: PET has a density of approximately 1.38 g/cm3, making it lightweight.

- Tensile strength: PET is known for its high tensile strength, with values ranging from 55 to 75 MPa, depending on the manufacturing process and the specific application.

- Flexural modulus: PET has a flexural modulus of around 2.5 GPa, indicating its high stiffness and resistance to deformation.

- Thermal expansion: PET has a coefficient of thermal expansion (CTE) of approximately 70-80 ppm/°C, which means it expands and contracts at a moderate rate in response to changes in temperature.

- Transparency: PET is a transparent material that allows visible light to pass through, making it suitable for packaging films and optical fibers.

- Water absorption: PET has low water absorption, which makes it resistant to moisture and humidity.

B. Physical properties of PI:

- Density: PI has a density of approximately 1.42 g/cm3, slightly higher than PET.

- Tensile strength: PI is known for its exceptional tensile strength, with values ranging from 120 to 220 MPa, depending on the specific grade and application.

- Flexural modulus: PI has a flexural modulus of around 4 GPa, which is higher than PET and indicates its greater resistance to deformation.

- Thermal expansion: PI has a very low CTE of approximately 20 ppm/°C, making it highly resistant to thermal expansion and contraction.

- Transparency: PI is typically opaque or translucent, depending on the specific formulation and processing methods.

- Water absorption: PI has very low water absorption, which makes it highly resistant to moisture and humidity.

C. Comparison between PET and PI:

Here’s a table summarizing the comparison between PET and PI based on their physical properties:

| Physical Property | PET | PI |

|---|---|---|

| Density | Approximately 1.38 g/cm3 | Approximately 1.42 g/cm3 |

| Tensile strength | 55-75 MPa | 120-220 MPa (depending on grade and application) |

| Flexural modulus | Approximately 2.5 GPa | Approximately 4 GPa |

| Thermal expansion | Approximately 70-80 ppm/°C | Approximately 20 ppm/°C |

| Transparency | Transparent | Opaque or translucent |

| Water absorption | Low | Very low |

As the table shows, PET and PI share some similarities, such as low water absorption and lightweight nature, but they also have significant differences. PI has higher tensile strength, flexural modulus, and thermal resistance, making it more suitable for high-temperature applications, while PET’s transparency and moderate stiffness make it better suited for applications such as packaging films and some electronic components.

Chemical Properties

In addition to their physical properties, the chemical properties of materials used in flexible printed circuit boards also play a significant role in their performance and suitability for specific applications. This section will explore the chemical properties of two commonly used materials in flex PCBs: polyester and polyimide. Understanding the unique chemical properties of these materials can help you choose the best option for your specific flex PCB needs.

A. Chemical properties of PET:

- Chemical resistance: PET is resistant to various chemicals, including alcohols, oils, and weak acids. However, it is less resistant to strong acids and bases.

- Hydrolysis resistance: PET is susceptible to hydrolysis, which can degrade its properties over time, particularly in the presence of moisture and high temperatures.

- UV stability: PET has good UV stability and is resistant to degradation from prolonged exposure to sunlight.

- Flammability: PET is a flammable material and can ignite when exposed to high heat or flame.

B. Chemical properties of PI:

- Chemical resistance: PI is highly resistant to many chemicals, including strong acids, bases, and organic solvents.

- Hydrolysis resistance: PI has excellent hydrolysis resistance, making it suitable for high-moisture environments.

- UV stability: PI has good UV stability, making it resistant to degradation from sunlight exposure.

- Flammability: PI is a self-extinguishing material and has good flame resistance.

C. Comparison between PET and PI:

Here’s a table summarizing the comparison between PET and PI based on their chemical properties:

| Chemical Property | PET | PI |

|---|---|---|

| Chemical resistance | Resistant to alcohols, oils, weak acids | Highly resistant to strong acids, bases, and organic solvents |

| Hydrolysis resistance | Susceptible to hydrolysis in the presence of moisture and high temperatures | Excellent hydrolysis resistance, suitable for high-moisture environments |

| UV stability | Good UV stability, resistant to degradation from sunlight exposure | Good UV stability, resistant to degradation from sunlight exposure |

| Flammability | Flammable material | Self-extinguishing material, good flame resistance |

As the table shows, PET and PI have different chemical properties, which can impact their performance and suitability for specific applications. PET is less resistant to strong acids and bases, while PI is highly resistant to a wide range of chemicals, including strong acids and bases. PI has excellent hydrolysis resistance, while PET is susceptible to hydrolysis in the presence of moisture and high temperatures. Finally, while PET and PI have good UV stability, PI is self-extinguishing and has good flame resistance, making it more suitable for high-temperature applications.

Applications

The unique properties of PET and PI make them popular choices for various applications. PET is commonly used in flex PCBs, packaging materials, and textiles, while PI is often used in aerospace, electronics, and medical device applications. In this section, we will explore the applications of these materials and how their unique properties make them suitable for specific uses. Understanding the applications of these materials can help you choose the best option for your specific needs.

A. Applications of PET:

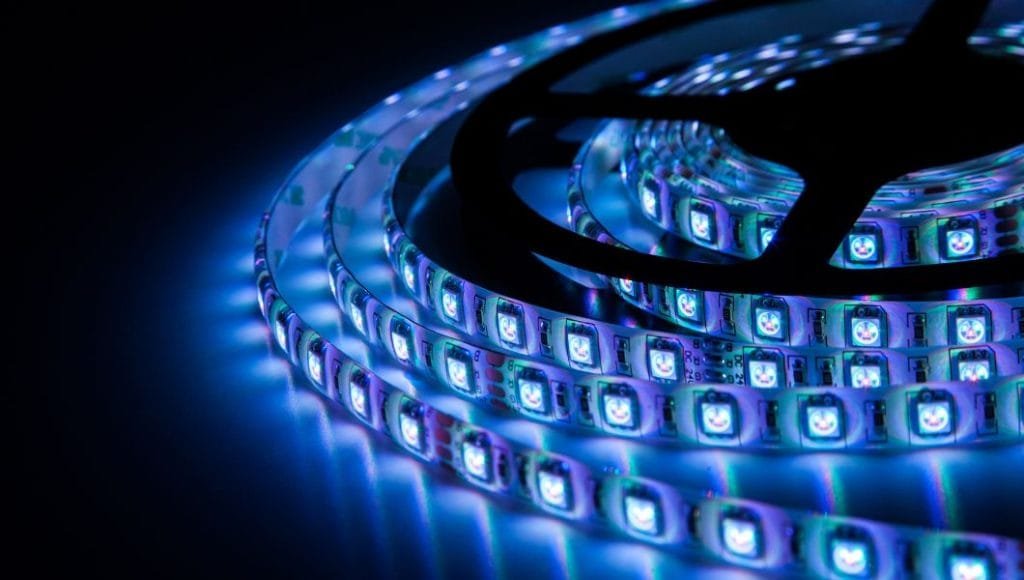

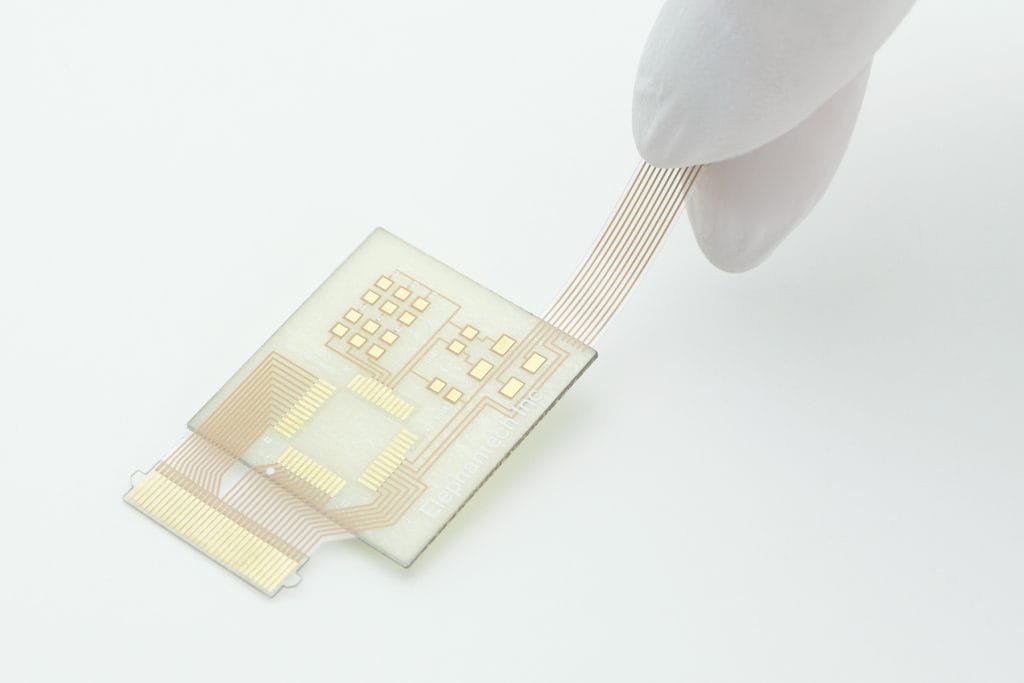

- Flexible printed circuit boards: PET is commonly used as a substrate material in flex PCBs due to its high flexibility, dimensional stability, and excellent electrical insulation properties.

- Packaging materials: PET is also used to manufacture food and beverage packaging materials, including bottles, trays, and films, due to its chemical resistance and ability to withstand high temperatures.

- Textile fibers: PET fibers are used to produce clothing and textiles, including polyester fabrics.

B. Applications of PI:

- Aerospace: PI is commonly used in aerospace applications, including electrical connectors, circuit boards, and insulation materials, due to its high-temperature resistance and excellent electrical insulation properties.

- Electronics: PI is also used in electronics applications, including flexible circuits, sensors, and displays, due to its excellent electrical properties and dimensional stability.

- Medical devices: PI is used in producing medical devices, including catheters, surgical instruments, and implantable devices, due to its biocompatibility and ability to withstand sterilization processes.

C. Comparison between PET and PI:

Both PET and PI have unique properties that make them suitable for various applications. PET is commonly used in flex PCBs and packaging materials due to its flexibility, dimensional stability, and excellent electrical insulation properties. On the other hand, PI is commonly used in high-temperature and electronics applications due to its excellent electrical properties, high-temperature resistance, and dimensional stability. Additionally, PI is used in medical devices due to its biocompatibility and ability to withstand sterilization processes. Overall, the choice between PET and PI for a specific application will depend on the specific properties required for the application in question.

Manufacturing Process

The manufacturing process of a material can impact its properties and suitability for specific applications. PET and PI are both produced through unique manufacturing processes that result in their unique properties and characteristics. In this section, we will explore the manufacturing processes of PET and PI and how they impact the properties of the final products. Understanding the manufacturing processes of these materials can help you choose the best option for your specific needs.

A. Manufacturing process of PET:

- Polymerization: PET is produced through a polymerization process involving the reaction of two monomers: ethylene glycol and terephthalic acid (or dimethyl terephthalate).

- Melt extrusion: Once the polymerization process is complete, the PET resin is melted and extruded into a thin film, which can be further processed into various products, including flex PCBs and packaging materials.

B. Manufacturing process of PI:

- Polymerization: PI is produced through a condensation polymerization process, which involves the reaction of two monomers: diamine and dianhydride.

- Solution casting: Once the polymerization process is complete, the PI resin is dissolved in a solvent and cast into a film or sheet, which can be further processed into various products, including high-temperature electronics components and aerospace materials.

C. Comparison between PET and PI:

The manufacturing processes for PET and PI are quite different. PET is produced through a melt extrusion process, while PI is produced through a solution casting process. Additionally, PET is produced through a polymerization process using ethylene glycol and terephthalic acid, while PI is produced through a condensation polymerization process using diamine and dianhydride. These differences in manufacturing processes can impact the properties and performance of the final products.

Environmental Impact

As society becomes increasingly aware of the impact of materials on the environment, it is important to consider the environmental impact of materials when choosing them for specific applications. In this section, we will explore the environmental impact of PET and PI, two commonly used materials in flex PCBs and other applications. Understanding the environmental impact of these materials can help us make more informed decisions about their use and disposal.

A. Environmental impact of PET:

PET is a plastic material often used in single-use items such as beverage bottles and packaging materials. While PET is considered to be a recyclable material, the process of recycling can still have environmental impacts. The production of PET requires the use of non-renewable resources such as crude oil, and the disposal of PET products can contribute to litter and waste accumulation in landfills and oceans.

B. Environmental impact of PI:

PI is a high-performance material often used in electronics and aerospace applications. While PI is not as commonly used as PET, it can still have environmental impacts. The production of PI requires non-renewable resources such as petroleum, and the disposal of PI products can contribute to waste accumulation in landfills.

C. Comparison between PET and PI:

Both PET and PI have environmental impacts associated with their production and disposal. PET is more commonly used in single-use items, which can contribute to waste accumulation. In contrast, PI is used in high-performance applications that require non-renewable resources. However, both materials are considered recyclable, and recycling can help reduce their environmental impact.

Conclusion

In conclusion, PET and PI are two distinct materials with unique properties that make them suitable for specific applications. When choosing between these materials, it is important to consider their physical, chemical, and environmental properties. As we continue to develop new materials that are more environmentally friendly, we may see changes in the materials used in flex PCBs and other applications in the future.

A. Differences between PET and PI:

PET and PI are distinct materials with unique physical, chemical, and environmental properties. PET is a more commonly used material in everyday applications, such as beverage bottles and packaging materials. At the same time, PI is a high-performance material often used in electronics and aerospace applications. The physical and chemical properties of these materials can impact their suitability for specific applications, and the environmental impact of their production and disposal should also be considered.

B. How to choose the material:

When choosing between PET and PI for a specific application, it is important to consider each material’s physical, chemical, and environmental properties. For example, PET may be more suitable for single-use items such as packaging materials. At the same time, PI may be more suitable for high-performance applications such as electronics and aerospace. Additionally, the environmental impact of the production and disposal of each material should be considered when making a decision.

C. Future development direction:

As society becomes increasingly aware of the impact of materials on the environment, developing sustainable materials is becoming more important. Researchers are working to develop new materials that are more environmentally friendly, including materials made from renewable resources and materials that are easier to recycle. The development of these new materials may lead to changes in the materials used in flex PCBs and other applications in the future.

Looking for high-quality and reliable PCB manufacturing services? Look no further than JHYPCB! As a leading provider of flexible PCBs, metal core PCBs, aluminum PCBs, heavy copper PCBs, and more, we’re committed to delivering top-notch products and services to meet your needs.

Email us at sales@pcbjhy.com or use our online quote request form to get a quick and accurate quote for your project. Our team of experienced professionals will work with you every step of the way to ensure that your PCBs are manufactured to your exact specifications and delivered on time.

So why wait? Contact JHYPCB today and experience the difference of working with a trusted and experienced PCB manufacturer!