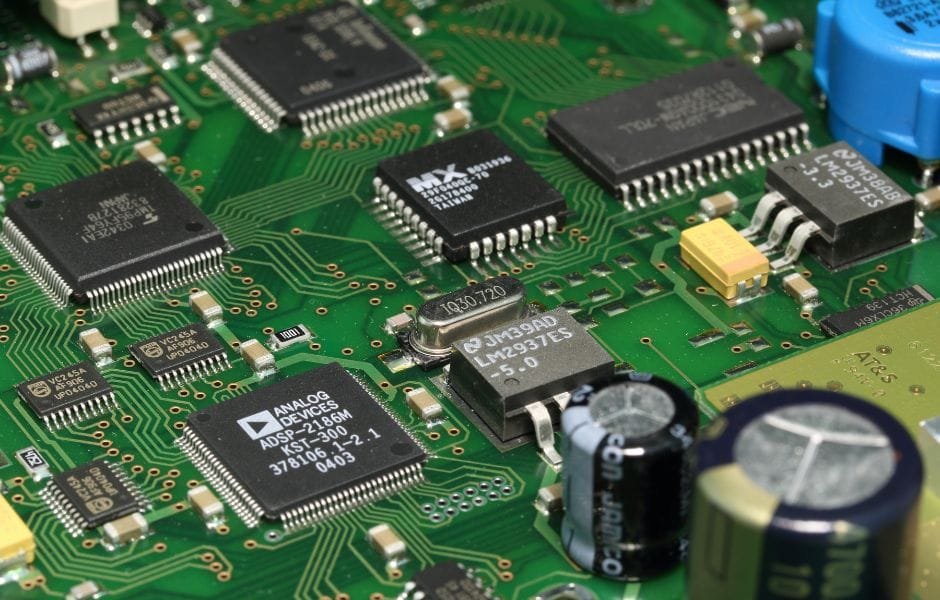

With electronic products becoming increasingly complex, PCB assembly has also become more challenging. Many companies find themselves lacking the necessary in-house resources and expertise to efficiently carry out PCB assembly. As a result, more and more companies are choosing to outsource PCB assembly to suppliers in China.

China has emerged as the preferred location for outsourcing PCB assembly. China has a robust supply chain infrastructure able to provide high-quality PCB assembly services at lower costs compared to Western nations. Chinese PCB assemblers can also rapidly scale production capacity up and down as needed. Additionally, Chinese suppliers often accept lower minimum order quantities than Western assemblers.

Outsourcing your PCB assembly to a Chinese company can bring many benefits to your business. The main advantages include lower costs, fast delivery times, high production capacity, and flexibility. PCB assembly experts in China have abundant experience and various certifications to meet your stringent quality requirements. If you choose the right outsourcing partner, contracting out your circuit board assembly can enable you to focus on core competencies and reduce investment in internal resources.

Benefits of Outsourcing PCB Assembly to China

Outsourcing PCB assembly to qualified partners in China offers numerous benefits that can give your business a competitive advantage. Here are some of the top reasons to consider Chinese companies for your circuit board assembly needs:

- Cost Savings

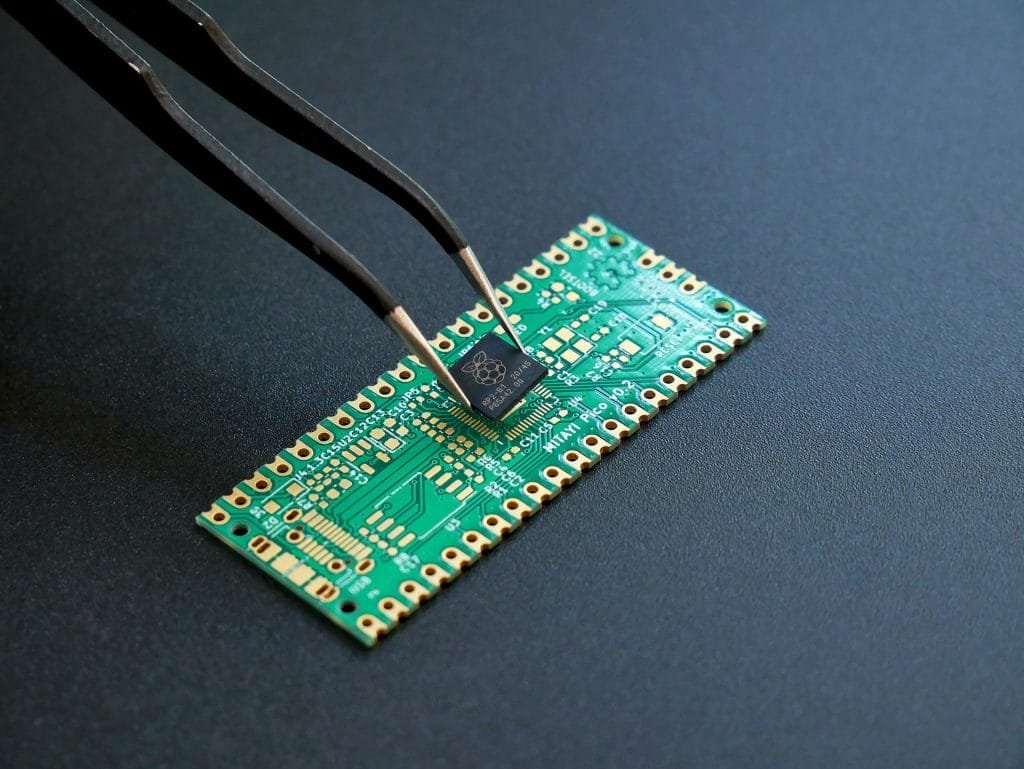

Lower labor costs and overheads in China enable contract manufacturers to assemble PCBs at a fraction of the cost of Western assemblers. By outsourcing production, you avoid investing in expensive equipment and labor. This results in significant cost savings you can leverage to reduce product costs. - High Production Capacity

China is home to a vast number of electronics manufacturers with extensive PCB assembly capabilities. Their production facilities are equipped with the latest technologies and staffed by skilled workers, allowing them to handle high-volume and complex assembly projects. This gives you access to virtually unlimited capacity. - Quick Turnaround Times

Locating your PCB assembly partner in China gives you close proximity to component suppliers in Asia. This, together with their efficiencies, enables Chinese assemblers to provide faster turnaround times, reducing your time-to-market. - Quality Components

You gain access to top-quality components for your assemblies from neighboring suppliers in Asia. Working with assemblers who source locally avoids long-lead items and ensures a smooth assembly process. - Flexibility

Chinese contract manufacturers are highly experienced in scaling production to meet fluctuating demand. They can easily ramp up or down to align with your changing requirements. - Low Minimum Order Quantities

Most Chinese PCB assembly providers can take on small-batch orders of a few hundred boards. Western assemblers often have higher minimum order requirements. Lower minimums give you flexibility with market testing and iterations.

Key Factors When Selecting a Chinese PCB Assembly Partner

Choosing the right PCB assembly partner in China is crucial to ensuring quality, protecting your IP, and building a successful long-term relationship. Here are some of the most important factors to consider during your supplier selection process:

- Experience and Reputation

Partner with an assembler that has an established presence in the industry and a proven track record delivering high-quality assemblies reliably over many years. Check reviews and testimonials to verify their capabilities. - Quality Certifications

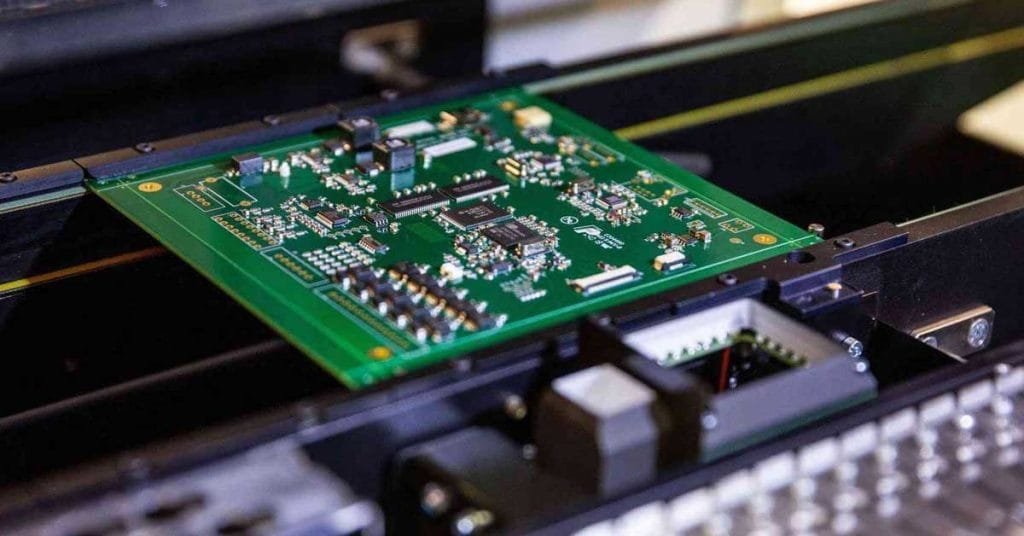

Look for partners holding certifications such as ISO 9001, ISO 13485, and IATF 16949. These validate their adherence to rigorous quality management standards and commitment to continuous improvement. - Production Capabilities

Assess their end-to-end assembly services, supported assembly types (SMT, through-hole, mixed-technology), capacity for your volumes, and experience with the components you require. - Customer Service

Responsiveness, English proficiency, and professionalism in customer service indicate how well they will collaborate with and support you. - Logistics and Supply Chain

Choose a strategic partner able to provide turnkey logistics, clear customs seamlessly, and give you inventory visibility. This ensures timely and cost-optimized delivery. - Security and IP Protection

Robust cybersecurity, confidentiality agreements, and measures to protect your IP are essential – especially for innovative products. - Pricing and Minimums

Compare pricing models (e.g. per component, by volume) and minimum order quantities across potential assemblers and negotiate favorable terms.

Vetting multiple manufacturers thoroughly before selecting a partner can help you avoid quality issues, delays, and IP risks further down the line.

Conclusion

Outsourcing PCB assembly to China offers numerous benefits for companies looking to reduce costs and improve turnaround times. With China’s skilled workforce, expansive production capacity, quality components, and supply chain infrastructure – PCB assembly providers in China can assemble boards efficiently at very competitive prices.

Partnering with the right supplier is key to a successful outsourcing relationship. Carefully assess potential partners based on their capabilities, quality, certifications, security measures, and customer service. Take the time to thoroughly evaluate multiple assemblers before selecting one.

By leveraging China’s manufacturing strengths through outsourcing, companies can focus their in-house efforts on core competencies and new product development rather than PCB assembly. This allows them to get innovative products to market faster and more cost-effectively.

In today’s electronics manufacturing landscape, partnering with a proven PCB assembly expert in China has become a crucial strategy for staying lean and competitive. Outsourcing to China can transform your production economics while also giving you access to world-class capabilities.

JHYPCB: a Reliable Outsourcing PCB Assembly Services Supplier in China

Partnering with a reliable PCB assembly services provider can help you save costs and ensure the high quality of the PCBAs. Our extensive experience and expertise ensure that we can offer cost-effective solutions based on your project requirements. Our outsourcing PCB assembly service includes turnkey/partial PCB assembly, component sourcing, PCB manufacturing, SMT PCB assembly, Through-hole technology PCB assembly, Mixed technology PCB assembly, etc.

Contact our PCB assembly experts today, we will be happy to provide you with cost-effective and high-quality PCB assembly outsourcing services.

Related Reading

- China’s Leading Manufacturer and Assembler of LED PCBs

- A Complete Guide to HS Codes For PCB & PCBA for Imports and Exports

- SMT Vs. SMD: Understanding The Key Differences

- SMT Assembly Vs. THT Assembly: What Is The Difference?

- SMT PCB Assembly: Advantages and Challenges of Surface Mount Technology

- Effective Strategies for Creating and Managing BOMs in PCB Assembly

- Building High Quality PCBs – A Comprehensive Guide

- PCB Component Sourcing: Exploring Global Markets for Better Options and Prices

- Trustworthy Suppliers: Your Key to Successful Component Sourcing