PCBs provide an easy and reliable way to connect electronic components and come in various types and materials. Among the most commonly used PCBs are Metal Core PCBs and FR4 PCBs. These two types of PCBs have different characteristics and are suitable for different applications. This article will compare Metal Core PCBs and FR4 PCBs, highlighting their differences and applications.

What is a Metal Core PCB?

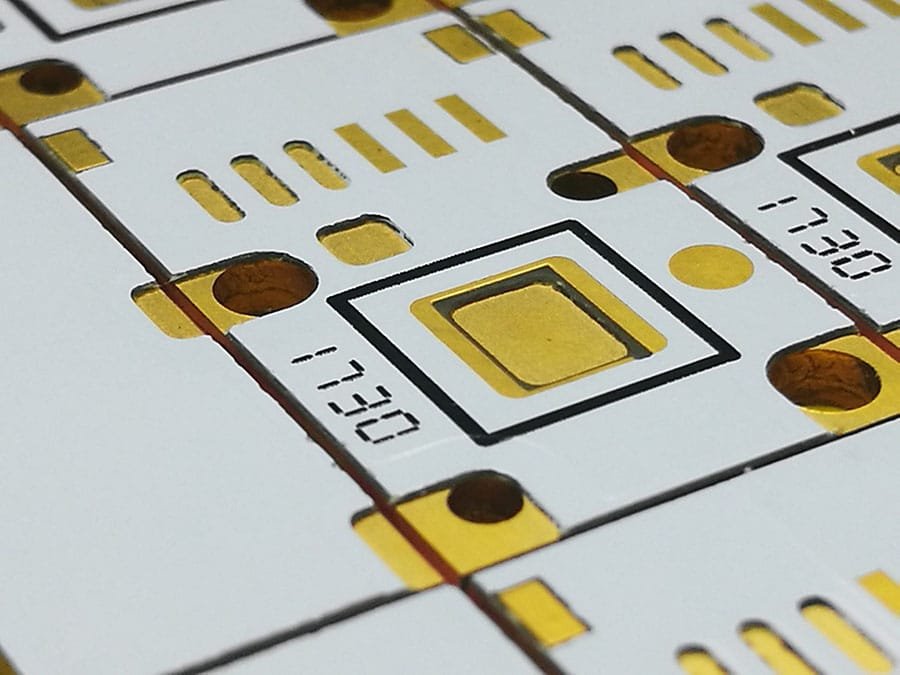

A Metal Core PCB (MCPCB) is a printed circuit board with a metal base, usually made of aluminum, as its core. The metal core provides better heat dissipation properties, making Metal Core PCBs ideal for applications that generate a lot of heat. Metal Core PCBs typically have a layer of copper on top of the metal core and a layer of solder mask and silkscreen on the other side. The metal core also provides better durability and mechanical strength to the PCB.

Advantages of Metal Core PCB over FR4

Heat Dissipation: Metal Core PCBs are excellent at dissipating heat. The metal core acts as a heat sink, efficiently transferring heat away from the electronic components. This property makes them ideal for applications that generate a lot of heat, such as LED lighting, power supplies, and high-power electronic devices.

Durability: The metal core provides better durability and mechanical strength to the PCB. Metal Core PCBs can withstand higher levels of shock and vibration, making them suitable for harsh environments and applications that require high reliability.

Reduced Size and Weight: The metal core also allows for the reduction of the size and weight of the PCB. The metal core has excellent thermal conductivity, which means that a Metal Core PCB can have a thinner copper layer and a smaller overall thickness than an FR4 PCB with the same heat dissipation capabilities. This property makes them ideal for applications where size and weight are critical, such as mobile devices and aerospace applications.

Applications of Metal Core PCBs

Metal Core PCBs are suitable for applications that require high heat dissipation, high reliability, and durability. Some of the most common applications of Metal Core PCBs include:

- LED lighting

- Power supplies

- Automotive electronics

- Aerospace applications

- High-power electronic devices

- Medical equipment

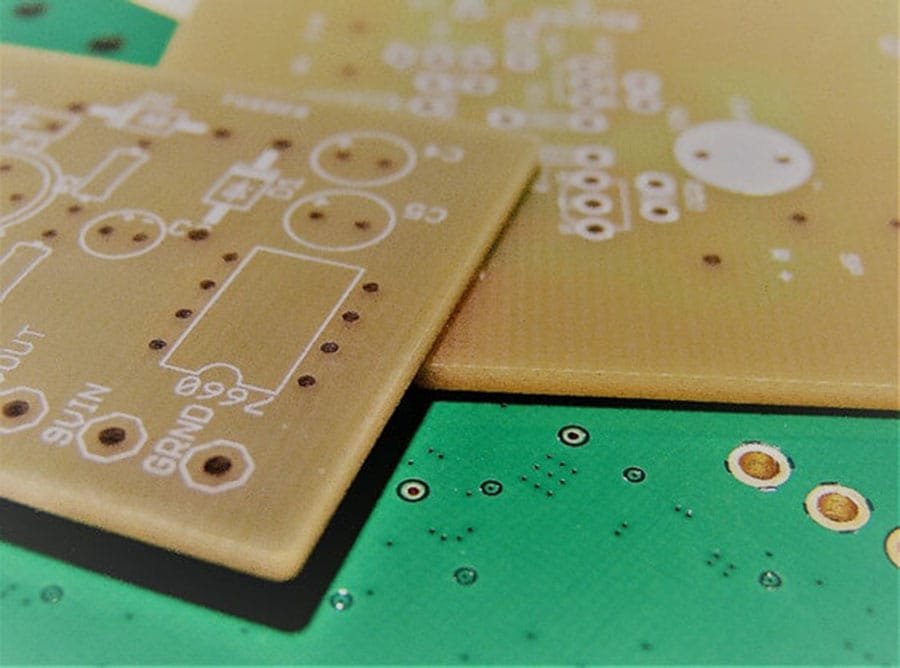

What is FR4 PCB?

FR4 PCBs, on the other hand, are the most common type of PCBs. They are made of a composite material consisting of a woven glass fabric core and epoxy resin. The FR4 material provides excellent insulation and mechanical strength to the PCB. The core is sandwiched between layers of copper, with a layer of solder mask and silkscreen on the other side.

Advantages of FR4 PCBs over Metal Core PCBs

Cost-effectiveness: FR4 PCBs are more cost-effective than Metal Core PCBs. The materials used to make FR4 PCBs are less expensive than the metal core used in Metal Core PCBs. Additionally, FR4 PCBs are easier to manufacture, reducing production costs.

Flexibility in Design: FR4 PCBs offer more flexibility in design than Metal Core PCBs. They can be made in different shapes and sizes, and they are suitable for applications that do not require high heat dissipation. FR4 PCBs are also easier to modify and repair than Metal Core PCBs.

Applications of FR4 PCBs

FR4 PCBs are suitable for a wide range of applications, including:

- Consumer electronics

- Computers

- Telecommunications

- Industrial control systems

- Medical equipment

- Aerospace and defense

Comparison between Metal Core PCBs and FR4 PCBs

Both Metal Core PCBs and FR4 PCBs have their advantages and disadvantages, and choosing the right type of PCB depends on the application requirements. Here are some key differences between the two types of PCBs:

Use Cases:

Metal Core PCBs are suitable for applications that require high heat dissipation, high reliability, and durability. They are ideal for applications such as LED lighting, power supplies, automotive electronics, and aerospace applications.

FR4 PCBs, on the other hand, are suitable for applications that do not require high heat dissipation. They are widely used in consumer electronics, computers, telecommunications, industrial control systems, and medical equipment.

Key Differences:

- Heat Dissipation: Metal Core PCBs have better heat dissipation properties than FR4 PCBs. The metal core acts as a heat sink, efficiently transferring heat away from the electronic components. FR4 PCBs, on the other hand, rely on the copper layers to dissipate heat.

- Durability: Metal Core PCBs are more durable and mechanically strong than FR4 PCBs. They can withstand higher levels of shock and vibration, making them suitable for harsh environments and high-reliability applications.

- Size and Weight: Metal Core PCBs can be smaller and lighter than FR4 PCBs with the same heat dissipation capabilities. This property makes them ideal for applications where size and weight are critical.

- Cost: FR4 PCBs are more cost-effective than Metal Core PCBs. The materials used to make FR4 PCBs are less expensive than the metal core used in Metal Core PCBs. Additionally, FR4 PCBs are easier to manufacture, reducing production costs.

- Flexibility in Design: FR4 PCBs offer more flexibility in design than Metal Core PCBs. They can be made in different shapes and sizes, and they are suitable for applications that do not require high heat dissipation. FR4 PCBs are also easier to modify and repair than Metal Core PCBs.

| Key Performance Indicators | Metal Core PCB | FR4 PCB |

|---|---|---|

| Heat Dissipation | Excellent heat dissipation due to metal core | Relies on copper layers for heat dissipation |

| Durability | More durable and mechanically strong | Less durable and mechanically weaker |

| Size and Weight | Can be smaller and lighter with same heat dissipation capabilities | Tends to be larger and heavier |

| Cost | More expensive due to the metal core | More cost-effective |

| Flexibility in Design | Limited in design flexibility | Offers more flexibility in design |

The above table shows the key performance indicators and how Metal Core PCBs and FR4 PCBs differ in each category. Metal Core PCBs offer excellent heat dissipation, higher durability, smaller and lighter size, but come at a higher cost and have limited design flexibility. FR4 PCBs, on the other hand, are more cost-effective, offer greater flexibility in design, but tend to be larger and heavier, less durable, and have less efficient heat dissipation. The choice between the two types of PCBs depends on the specific requirements of the application.