Introduction

Metal core printed circuit boards are becoming increasingly popular in advanced electronics and high-tech devices that require enhanced thermal management and electrical performance. As opposed to standard PCBs made of insulating FR4 material, metal core PCBs utilize a metal base laminate such as aluminum, copper, invar, or kovar as the substrate or core. The metal core provides significantly higher thermal conductivity allowing the PCB to dissipate heat efficiently from power components and high-frequency processors mounted on the board. This improves the PCB’s ability to manage heat dissipation as well as minimize thermal warping and instability. Metal core PCBs enable circuit designers to meet challenging thermal requirements and prevent overheating issues in small, congested PCBs handling high power density. With their noise-free electrical properties and low coefficient of thermal expansion, metal core PCBs are the ideal solution for avionics, telecom infrastructure, industrial automation, automotive electronics, IoT devices, and other applications where reliability and electrical performance are critical factors. This article will provide an overview of the most common types of metal core PCB constructions available.

Metal Core PCB Types

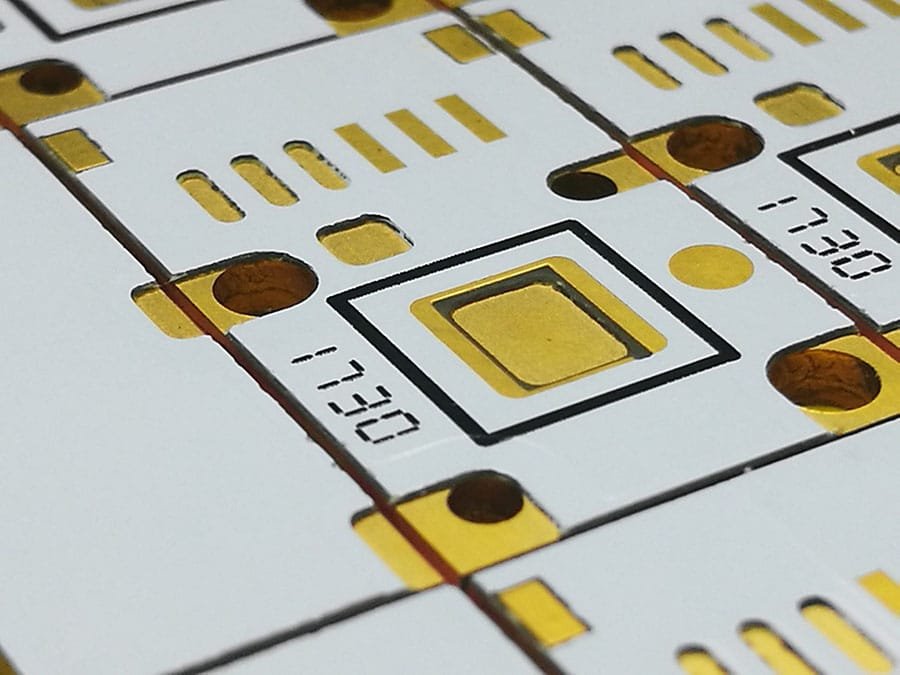

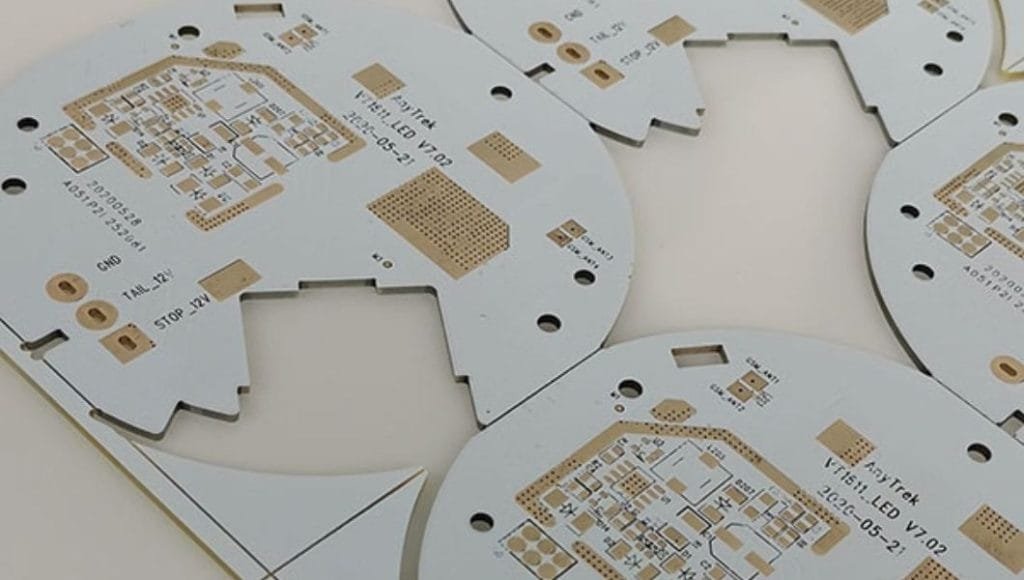

Aluminum-based PCBs are the most common type of MCPCBs. They are made by laminating a thin layer of aluminum to a non-conductive dielectric material, such as FR-4 or polyimide. The aluminum layer provides excellent heat dissipation and is suitable for high-power LED applications.

- Features

Aluminum-based PCBs have several features that make them a popular choice for many applications. These include:

- High thermal conductivity: Aluminum has a thermal conductivity of 205 W/mK, which makes it an excellent heat conductor.

- Lightweight: Aluminum is lightweight, which makes it suitable for applications where weight is a concern.

- Good electrical conductivity: Aluminum has good electrical conductivity, which ensures good signal transmission.

- Low cost: Aluminum is relatively inexpensive compared to other metal core PCB materials.

- Applications

Aluminum-based PCBs are commonly used in the following applications:

- LED lighting: High-power LEDs generate a lot of heat, which can reduce their lifespan. Aluminum-based PCBs can dissipate this heat, increasing the lifespan of the LED.

- Automotive industry: Aluminum-based PCBs are used in automotive applications such as engine control units and LED lighting.

- Power electronics: Aluminum-based PCBs are commonly used in power electronic applications such as motor drives, inverters, and switch mode power supplies.

- Pros and Cons

Aluminum-based PCBs have several advantages and disadvantages, including:

Pros:

- High thermal conductivity

- Lightweight

- Good electrical conductivity

- Low cost

Cons:

- Low strength

- Limited availability of large sizes

- Limited compatibility with soldering processes

2. Copper-based PCBs

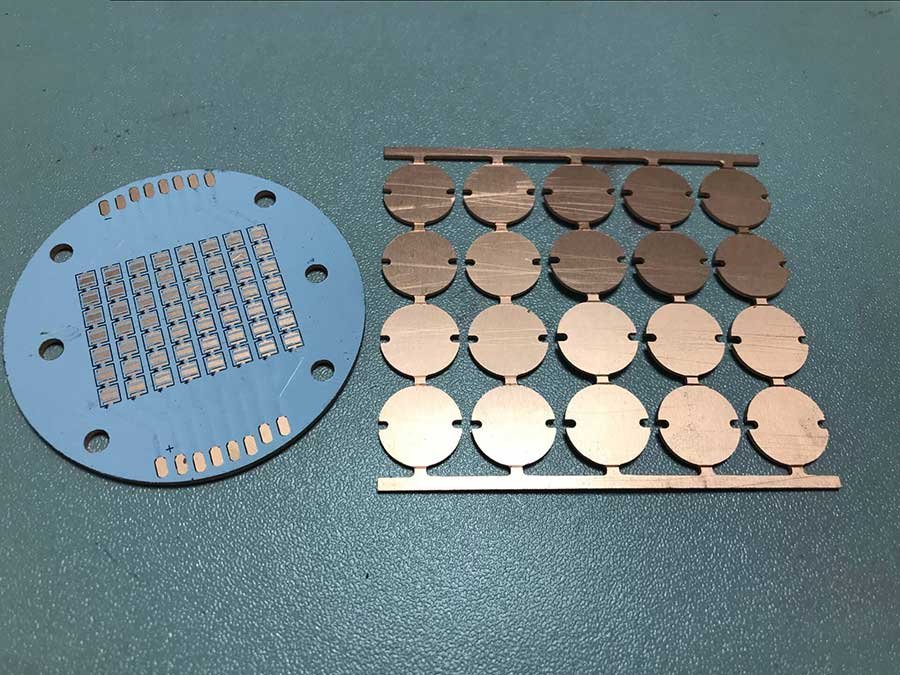

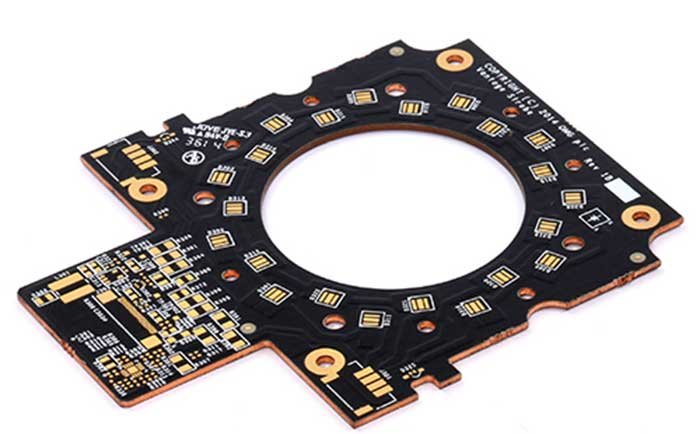

Copper-based PCBs are made by laminating a thin layer of copper to a non-conductive substrate, such as FR-4 or polyimide. The copper layer provides excellent thermal conductivity and electrical conductivity, making it suitable for high-power applications.

- Features

Copper-based PCBs have several features that make them a popular choice for many applications. These include:

- High thermal conductivity: Copper has a thermal conductivity of 385 W/mK, which makes it an excellent heat conductor.

- Good electrical conductivity: Copper has excellent electrical conductivity, which ensures good signal transmission.

- High strength: Copper is a strong metal, which makes it suitable for applications where strength is a concern.

- High compatibility with soldering processes: Copper is highly compatible with most soldering processes.

- Applications

Copper-based PCBs are commonly used in the following applications:

- High-power electronics: Copper-based PCBs are commonly used in high-power applications such as power supplies, motor drives, and inverters.

- Automotive industry: Copper-based PCBs are used in automotive applications such as engine control units and LED lighting.

- Aerospace industry: Copper-based PCBs are used in aerospace applications such as avionics and satellite communication systems.

- Pros and Cons

Copper-based PCBs have several advantages and disadvantages, including:

Pros:

- High thermal conductivity

- Good electrical conductivity

- High strength

- High compatibility with soldering processes

Cons:

- Expensive compared to other metal core PCB materials

- Heavier than other metal core PCB materials

- Poor compatibility with surface mount technology (SMT)

3. Iron-based PCBs

Iron-based PCBs are made by laminating a thin layer of iron to a non-conductive substrate, such as FR-4 or polyimide. Iron has a relatively low thermal conductivity compared to aluminum and copper, but it is much cheaper and widely available.

- Features

Iron-based PCBs have several features that make them a popular choice for many applications. These include:

- Low cost: Iron is relatively inexpensive compared to other metal core PCB materials.

- Good strength: Iron is a strong metal, which makes it suitable for applications where strength is a concern.

- Good magnetic properties: Iron has good magnetic properties, which make it suitable for applications where magnetic fields are involved.

- Applications

Iron-based PCBs are commonly used in the following applications:

- Low-power electronics: Iron-based PCBs are commonly used in low-power applications such as audio amplifiers and radio frequency (RF) circuits.

- Magnetic applications: Iron-based PCBs are used in applications where magnetic fields are involved, such as inductors and transformers.

- Pros and Cons

Iron-based PCBs have several advantages and disadvantages, including:

Pros:

- Low cost

- Good strength

- Good magnetic properties

Cons:

- Low thermal conductivity

- Heavy compared to other metal core PCB materials

- Limited availability of large sizes

Comparison

A. Features Comparison

When choosing a metal core PCB, it is essential to consider the features of each type. The table below compares the features of aluminum-based, copper-based, and iron-based PCBs.

| Features | Aluminum-based PCBs | Copper-based PCBs | Iron-based PCBs |

|---|---|---|---|

| Thermal conductivity | High | High | Low |

| Electrical conductivity | Good | Excellent | Good |

| Strength | Low | High | High |

| Compatibility with SMT | Limited | Poor | Good |

| Cost | Low | High | Low |

B. Applications Comparison

The table below compares the applications of aluminum-based, copper-based, and iron-based PCBs.

| Applications | Aluminum-based PCBs | Copper-based PCBs | Iron-based PCBs |

|---|---|---|---|

| LED lighting | ✓ | – | – |

| Automotive industry | ✓ | ✓ | – |

| Power electronics | ✓ | ✓ | – |

| High-power electronics | – | ✓ | – |

| Aerospace industry | – | ✓ | – |

| Low-power electronics | – | – | ✓ |

| Magnetic applications | – | – | ✓ |

C. Pros and Cons Comparison

The table below compares the pros and cons of aluminum-based, copper-based, and iron-based PCBs.

| Pros | Aluminum-based PCBs | Copper-based PCBs | Iron-based PCBs |

|---|---|---|---|

| High thermal conductivity | ✓ | ✓ | – |

| Good electrical conductivity | ✓ | ✓ | ✓ |

| High strength | – | ✓ | ✓ |

| Compatibility with soldering processes | – | ✓ | – |

| Low cost | ✓ | – | ✓ |

| Heavier than other metal core PCB materials | – | ✓ | ✓ |

| Limited availability of large sizes | ✓ | – | ✓ |

| Limited compatibility with SMT | ✓ | – | ✓ |

Benefits of Metal Core PCBs

Compared to standard FR4 circuit boards, metal core PCBs provide superior thermal heat dissipation, electrical performance, and structural stability – key factors for electronics operating in demanding conditions. The high thermal conductivity of metals like aluminum and copper enables metal core PCBs to conduct heat away from sensitive components much more effectively than an FR4 board. This allows for better temperature control and prevention of hot spots even when high power circuits and processors are tightly packed on the PCB. With thermal management taken care of, metal core PCBs can accommodate greater power densities without overheating.

Additionally, the electrical properties of metal substrates result in less signal loss, noise, and interference at high frequencies and speeds compared to standard PCB dielectrics. This makes metal core PCBs well suited for RF, microwave, and other high frequency applications up to gigahertz levels. The dimensional stability of metals also resist mechanical warping across a wide thermal range, helping to prevent structural failures due to temperature changes and gradients. For advanced circuits where reliability and precision are critical, metal core PCBs deliver marked improvements in heat dissipation, electrical efficiency, and structural stability under challenging operating conditions.

Order Guide

A. How to Choose a Metal Core PCB

When choosing a metal core PCB, it is essential to consider the following factors:

- Thermal conductivity: Choose a metal core PCB with a high thermal conductivity if you are dealing with high-power applications.

- Electrical conductivity: Choose a metal core PCB with good electrical conductivity to ensure good signal transmission.

- Strength: Choose a metal core PCB with high strength if the application requires it.

- Compatibility with soldering processes: Choose a metal core PCB that is compatible with the soldering process used in your manufacturing process.

- Cost: Choose a metal core PCB that fits within your budget.

- Availability of large sizes: Choose a metal core PCB that is available in the size you need for your application.

B. Where to Buy Metal Core PCBs

Metal core PCBs can be purchased from a variety of sources, including:

- PCB manufacturers: Many PCB manufacturers specialize in metal core PCBs and can produce them to your specifications.

- Online marketplaces: Online marketplaces like Alibaba, Amazon, and eBay can be a good source for metal core PCBs.

- Local electronics stores: Some electronics stores may carry metal core PCBs or be able to order them for you.

C. How to Order Metal Core PCBs

When ordering metal core PCBs, it is essential to provide the following information:

- Board thickness: The thickness of the metal core PCB is an important consideration for the application. Provide the thickness required for your application.

- Base material: Specify the non-conductive base material you want to use for your metal core PCB, such as FR-4 or polyimide.

- Metal core material: Specify the metal core material you want to use for your PCB, such as aluminum, copper, or iron.

- Surface finish: Specify the surface finish you want to use for your metal core PCB, such as ENIG, OSP, or HASL.

- Copper weight: Specify the weight of the copper layer you want to use for your metal core PCB.

- Hole size and placement: Provide the hole size and placement required for your application.

- Solder mask color: Specify the solder mask color you want to use for your metal core PCB.

- Silkscreen color: Specify the silkscreen color you want to use for your metal core PCB.

- Quantity: Specify the quantity of metal core PCBs you need for your application.

Conclusion

Metal core PCBs are an essential component in many electronic devices and systems, especially those that require high power or generate heat. Choosing the right type of metal core PCB for your application is essential to ensure the best performance and reliability. Aluminum-based PCBs offer high thermal conductivity and good electrical conductivity, while copper-based PCBs offer excellent electrical conductivity and high strength. Iron-based PCBs offer a low-cost alternative with good strength and magnetic properties. When choosing a metal core PCB, it is essential to consider the features, applications, and pros and cons of each type, as well as factors such as thermal conductivity, electrical conductivity, strength, cost, and availability.