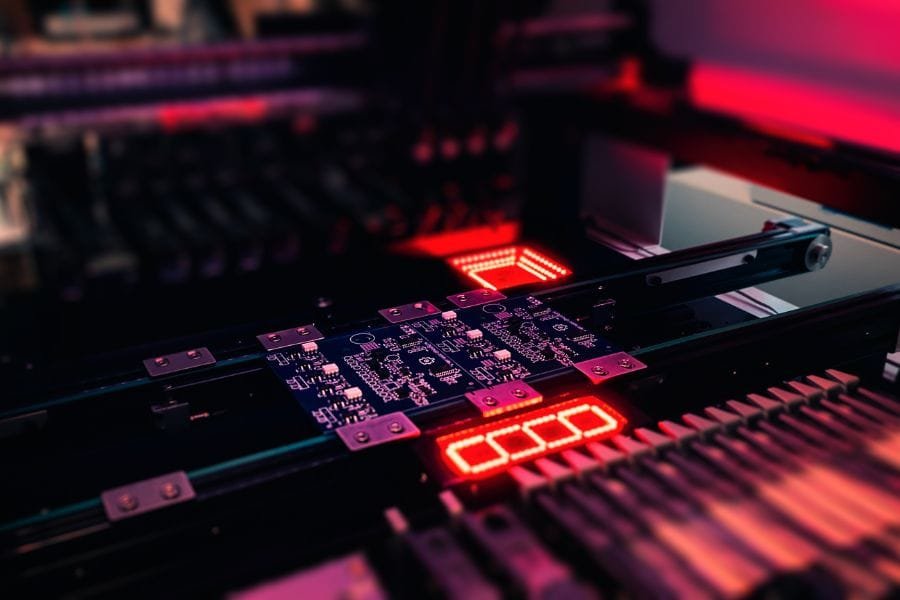

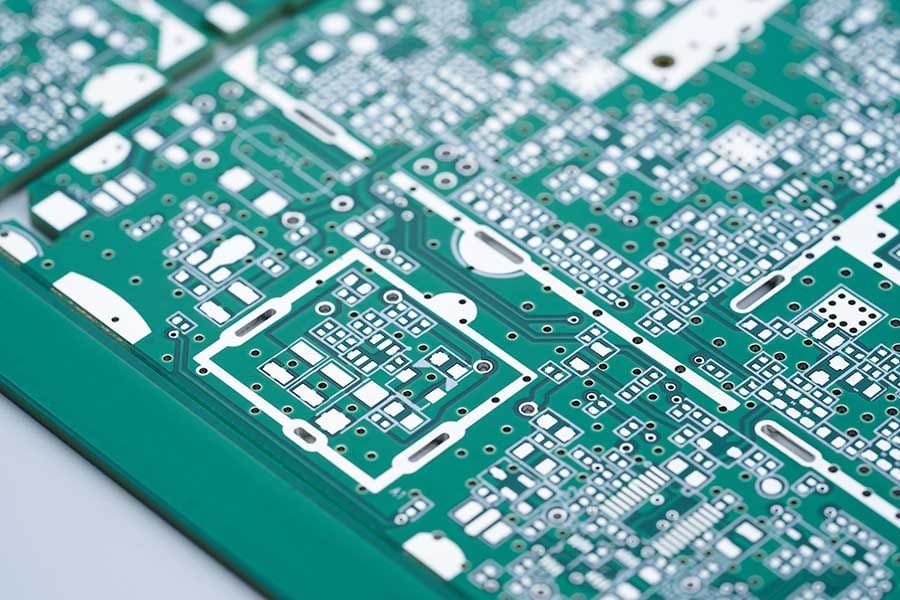

High Tg PCBs, or printed circuit boards with high glass transition temperatures, are becoming increasingly important in modern electronics. These advanced PCBs offer improved thermal stability, mechanical strength, and durability, making them ideal for applications in aerospace, defense, automotive, and industrial electronics. In this article, we will explore real-world examples and success stories of High Tg PCB applications, highlighting the benefits and advantages of this technology. From miniaturized medical devices to high-temperature industrial applications, High Tg PCBs are enabling new levels of performance, reliability, and functionality. As electronic systems continue to evolve and demand higher levels of performance, High Tg PCBs will play a critical role in meeting these challenges. Whether you are an engineer, designer, or manufacturer, understanding the benefits and applications of high-Tg PCBs is essential for staying ahead of the curve in today’s fast-paced electronics industry.

What is High Tg PCB?

High Tg PCB stands for high glass transition temperature printed circuit board. Glass transition temperature (Tg) is the temperature at which the epoxy resin material is used to make the PCB transition from a glassy state to a rubbery state. High Tg PCBs are made with specialized resin materials that have a higher Tg than standard PCB materials. The higher Tg provides improved thermal stability, mechanical strength, and durability, making High Tg PCBs ideal for applications where the PCBs may be subjected to high temperatures or high mechanical stress. High Tg PCBs are commonly used in aerospace, defense, automotive, and industrial electronics, where reliability and performance are critical. By using High Tg PCBs, designers and manufacturers can achieve higher levels of performance and reliability, while also reducing the risk of failure or degradation over time.

Benefits of High Tg PCBs

High Tg PCBs offer significant advantages over standard PCB materials, allowing designers and manufacturers to achieve higher levels of performance and reliability in their electronic systems. Here are some of the benefits of High Tg PCBs:

- High thermal stability and resistance to high temperatures: High Tg PCBs have a higher glass transition temperature than standard PCB materials, which means they can withstand higher temperatures without degrading. This makes them ideal for applications where the PCB may be exposed to high temperatures, such as in automotive, aerospace, and industrial electronics.

- High mechanical strength and durability: High Tg PCBs have improved mechanical properties, including higher strength, stiffness, and resistance to deformation. This makes them less prone to cracking or warping under high mechanical stress or vibration, which is important in applications where the PCB may be subjected to harsh environmental conditions.

- Improved signal integrity and reduced noise: High Tg PCBs have lower dielectric loss and better signal propagation characteristics than standard PCB materials. This leads to improved signal integrity and reduced noise in high-speed and high-frequency applications, such as telecommunications and data communication systems.

- Enhanced reliability and longer lifespan: High Tg PCBs have a lower risk of failure or degradation over time, due to their improved thermal stability, mechanical strength, and signal integrity. This leads to enhanced reliability and longer lifespan of the electronic systems in which they are used.

Real-world examples of High Tg PCB applications

High Tg PCBs offer numerous advantages in a wide range of real-world applications, enabling higher levels of performance, reliability, and durability in electronic systems. Here are some real-world examples of High Tg PCB applications:

- Aerospace and Defense Industry:

High Tg PCBs are widely used in the aerospace and defense industry, where reliability, durability, and thermal stability are crucial. For example, High Tg PCBs are used in satellites and spacecraft, where they must withstand extreme temperatures and harsh environmental conditions. High Tg PCBs are also used in military communication and radar systems, where they must perform reliably under high mechanical stress and vibration. - Automotive Industry:

High Tg PCBs are increasingly used in the automotive industry, particularly in advanced driver assistance systems (ADAS) and electric vehicles (EVs). ADAS systems require PCBs with high thermal stability and durability to withstand the harsh conditions of automotive environments. EVs require PCBs with high mechanical strength and resistance to deformation, due to the high torque and vibration of the electric drivetrain. - Industrial Electronics:

High Tg PCBs are used in a variety of industrial electronics applications, such as power electronics and industrial automation and control systems. Power electronics require PCBs with high thermal stability and low dielectric loss to ensure reliable and efficient operation. Industrial automation and control systems require PCBs with high mechanical strength and durability to withstand harsh industrial environments and ensure long-term reliability.

Success stories of High Tg PCB Applications

High Tg PCBs have been proven to provide a range of benefits in various electronic applications, including medical devices, telecommunications systems, and industrial power electronics. This section presented three real-world case studies demonstrating the success of High Tg PCBs in enabling miniaturization and increased functionality in a medical device, improving reliability and durability in a high-temperature industrial application, and increasing signal integrity and reducing noise in a telecommunications system. These success stories showcase the advantages of High Tg PCBs in improving the performance, reliability, and durability of electronic systems, and highlight their potential to enable innovation and competitiveness in various industries.

- Case study 1: High Tg PCBs enable miniaturization and increased functionality in a medical device.

A medical device manufacturer in the United States was looking to develop a new implantable device that would be smaller, more reliable, and have increased functionality. However, the existing PCB materials they were using were unable to meet the requirements of the new design. They needed a material with high thermal stability and mechanical strength, as well as the ability to withstand the harsh conditions of the human body.

After researching various PCB materials, the manufacturer decided to switch to High Tg PCBs. The higher glass transition temperature and improved mechanical properties of the High Tg PCBs allowed for miniaturization of the device, while also increasing its reliability and durability. The High Tg PCBs also enabled the addition of new features, such as wireless connectivity and real-time monitoring of the device’s performance.

The use of High Tg PCBs enabled the manufacturer to develop a smaller, more reliable, and more functional medical device that has since been successfully deployed in the market.

- Case study 2: High Tg PCBs improve reliability and durability in a high-temperature industrial application.

An industrial equipment manufacturer in Japan was experiencing reliability issues with their motor drives, which were operating at high temperatures and under high mechanical stress. The existing PCB materials were unable to withstand the harsh conditions, leading to failures and downtime.

After researching various PCB materials, the manufacturer decided to switch to High Tg PCBs with improved thermal stability and mechanical strength. The High Tg PCBs were able to withstand the high temperatures and mechanical stress, resulting in improved reliability and durability of the motor drives. The use of High Tg PCBs also enabled the manufacturer to increase the power density of the motor drives, leading to improved efficiency and reduced size and weight of the equipment.

The use of High Tg PCBs enabled the manufacturer to improve the reliability and durability of their industrial equipment, resulting in reduced downtime and increased customer satisfaction.

- Case study 3: High Tg PCBs increase signal integrity and reduce noise in a telecommunications system

A telecommunications equipment manufacturer in South Korea was experiencing issues with signal integrity and noise in their routers, which were operating at high speeds and frequencies. The existing PCB materials were unable to provide the required dielectric properties, leading to degraded signal quality and increased noise.

After researching various PCB materials, the manufacturer decided to switch to High Tg PCBs with improved dielectric properties. The High Tg PCBs were able to reduce the dielectric loss and improve the signal propagation characteristics, resulting in improved signal integrity and reduced noise. The use of High Tg PCBs also enabled the manufacturer to increase the data transfer rates of their routers, leading to improved performance and customer satisfaction.

The use of High Tg PCBs enabled the manufacturer to improve the signal quality and reduce the noise in their telecommunications equipment, resulting in improved performance and customer satisfaction.

Conclusion

High Tg PCBs play a critical role in enabling the development of innovative and reliable electronic systems. The higher glass transition temperature and improved mechanical properties of High Tg PCBs offer numerous benefits, including better thermal stability, increased functionality, improved reliability, and reduced failure rates. High Tg PCBs are particularly beneficial for high-temperature applications and harsh environments where traditional PCB materials may not be sufficient.

As the demand for more advanced and reliable electronic systems continues to increase, High Tg PCB technology is also evolving to meet these demands. Future developments in High Tg PCBs are expected to focus on improving their performance, reliability, and durability under even more extreme conditions. Additionally, advances in manufacturing techniques and materials are expected to enable the development of even smaller and more complex High Tg PCBs.

If you’re interested in using High Tg PCBs for your electronic applications, we’re here to help. At JHYPCB, we offer high-Tg PCB manufacturing services to help you achieve your goals. You can contact us at sales@pcbjhy.com, or upload your Gerber files on our online quotation page to get a quote. Don’t hesitate to reach out to us with any questions or inquiries. We look forward to working with you.