As the demand for flexible and lightweight electronic devices continues to rise, the popularity of flexible printed circuit boards has grown significantly in recent years. Flexible PCBs are widely used in various industries, including medical, automotive, aerospace, and consumer electronics, due to their ability to bend and twist without breaking. However, the cost of producing these boards can vary greatly depending on several factors. In this blog post, we’ll explore the pricing of flexible PCBs, factors contributing to the cost, market trends, and cost-saving strategies.

Table of Contents

What is Flexible PCB?

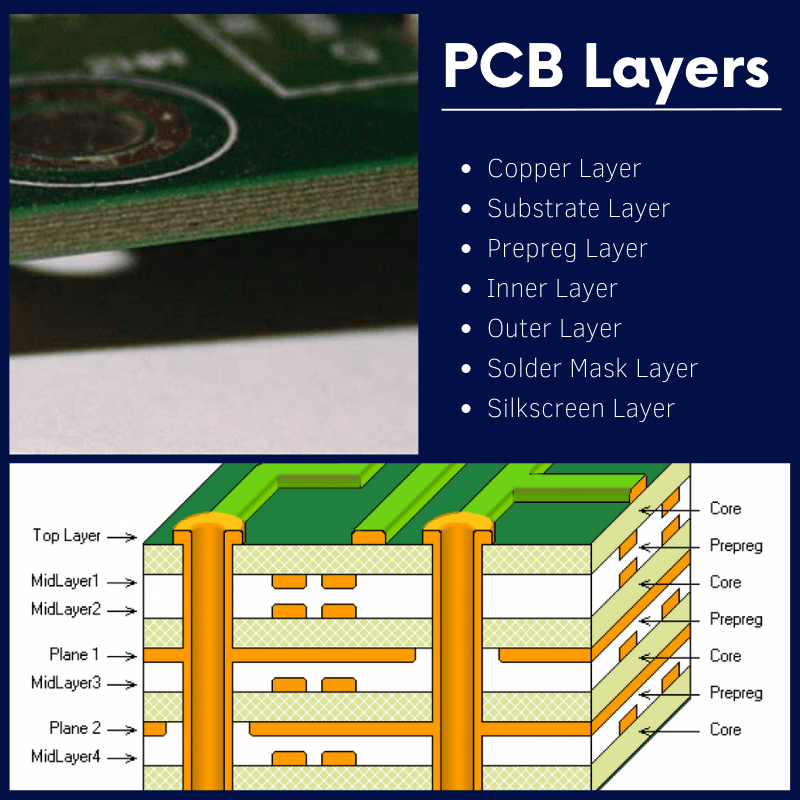

Flexible printed circuit boards are a type of PCB that can be bent, folded, and twisted without losing functionality. These boards are made of flexible materials such as polyimide, polyester, or thin-film polymers that are more pliable than traditional rigid PCBs. The components on a flexible PCB are mounted on a flexible substrate, allowing the board to bend and conform to the shape of the product it’s used in. Flexible PCBs are commonly used in electronic devices such as wearables, smartphones, laptops, and medical devices. The unique properties of flexible PCBs make them ideal for applications where space is limited or flexibility and durability are essential.

Factors Affecting the Pricing of Flexible PCBs

The cost of producing flexible PCBs can vary depending on several factors. The three main factors contributing to the cost are material costs, production costs, and management costs.

Material costs: The cost of the materials used to make flexible PCBs can significantly impact the overall cost of the boards. The primary material used in flexible PCBs is the substrate, typically made of flexible materials such as polyimide or polyester. The substrate material cost depends on the material’s thickness, size, and quality. Other materials used in flexible PCBs, such as copper foil, coverlay, and adhesive, also contribute to the material cost.

Production costs: The complexity of the board design directly affects production costs. For example, a single-layer flexible PCB typically costs less to produce than a double-layer FPC board of the same size. Additionally, the number of components and their placement can influence costs – densely packed boards with fine-pitch components require more sophisticated manufacturing techniques, increasing production time and costs.

Management costs: The management cost includes the expenses associated with managing the production process, such as quality control, logistics, and customer support. The manufacturer incurs these costs to ensure that the boards meet the required specifications and are delivered to the customer on time.

Overall, the price of flexible PCBs is determined by a combination of these factors, and the final cost may vary depending on the manufacturer’s pricing strategy, volume discounts, and the customer’s specific requirements.

Catching the Wave: An Analysis of Current and Future Pricing Trends for Flexible PCBs

Now, let’s dive into the pricing trends for flexible PCBs:

The market for flexible PCBs has seen significant growth in recent years due to the increasing demand for flexible and wearable electronic devices. This growth has also led to increased competition among manufacturers, resulting in fluctuating prices for flexible PCBs.

One pricing trend in the flexible PCB market is the downward price trend over the past few years. This trend can be attributed to the advancements in manufacturing technology, which have increased production efficiency, reduced material costs, and lowered labor costs. As a result, some manufacturers have been able to offer more competitive prices to their customers.

However, the pricing trend for flexible PCBs is not uniform across all product segments. The pricing of flexible PCBs for high-end applications, such as aerospace and medical devices, is relatively stable due to the stringent quality requirements and low production volume. In contrast, the pricing of flexible PCBs for consumer electronics is more volatile due to the high production volume and intense competition.

Looking toward the future, the pricing trend for flexible PCBs will continue to be influenced by market demand and technological advancements. As the market for flexible electronics continues to grow, the demand for flexible PCBs will likely increase, leading to more competition and potentially lower prices. Additionally, as manufacturing technology advances, manufacturers may be able to produce flexible PCBs more efficiently and cost-effectively, leading to further price reductions.

The flexible printed circuit board market size has grown rapidly in recent years. It will grow from $23.63 billion in 2023 to $26.2 billion in 2024 at a compound annual growth rate (CAGR) of 10.9%. The expansion observed in the historical period can be credited to the trend of electronic device miniaturization, which has spurred the need for compact circuitry. Additionally, the surge in consumer electronics has heightened the demand for flexible PCBs, while advancements in medical devices have driven innovation in space-efficient circuitry. Furthermore, the military and aerospace sectors have sought lightweight and durable PCBs for their applications, and there has been growing demand from industrial automation for flexible PCB solutions.

The flexible printed circuit board market size is expected to see rapid growth in the next few years. It will grow to $38.81 billion in 2028 at a compound annual growth rate (CAGR) of 10.3%.Flexible Printed Circuit Board Global Market Report 2024 - RESEARCH AND MARKETS

Maximizing Value: Strategies to Reduce the Cost of Flexible PCBs

While the pricing of flexible PCBs can vary depending on several factors, there are several strategies that manufacturers can employ to reduce the cost and increase their value proposition:

Design optimization: Design optimization involves designing a flexible PCB using materials and production methods most efficiently. This strategy can help reduce the amount of material waste, minimize production time, and lower overall production costs.

Material selection: Choosing the right materials for the flexible PCB can significantly impact the cost. Manufacturers can select materials that offer the required performance while minimizing costs. For example, choosing a thinner substrate or a lower-cost coverlay material can help reduce material costs without compromising performance.

Volume discounts: Manufacturers can offer discounts to customers who order large quantities of flexible PCBs. This strategy incentivizes customers to order more units, which can help manufacturers achieve economies of scale and reduce production costs.

Supply chain optimization: Optimizing the supply chain can help manufacturers reduce logistics, transportation, and raw material procurement costs. Manufacturers can work with suppliers to negotiate better pricing, consolidate shipments, and optimize inventory management.

Continuous improvement involves ongoing efforts to improve production efficiency, reduce waste, and optimize processes. Manufacturers can implement lean manufacturing techniques, invest in new equipment and technology, and streamline production workflows to reduce costs and improve quality.

By employing these cost-saving strategies, manufacturers can reduce the cost of flexible PCBs without compromising quality or performance, making their products more competitive in the market.

The Customer Comes First: Tips for Reducing the Cost of Your Flexible PCBs

While manufacturers can employ several strategies to reduce the cost of flexible PCBs, customers can also take steps to minimize their costs. Here are some tips for customers to consider when ordering flexible PCBs:

Plan: Planning and ordering in advance can help customers avoid rush fees and expedited shipping costs. Customers can also take advantage of volume discounts by ordering larger flexible PCBs.

Simplify the design: Simplifying the design of the flexible PCB can help reduce material costs, production time, and overall production costs. Customers can work with the manufacturer to identify opportunities to simplify the design without compromising performance.

Choose standard sizes: Choosing standard sizes for the flexible PCB can help reduce tooling costs and minimize waste. Manufacturers may have standard sizes available, which can help reduce production lead times and overall costs.

Be open to alternative materials: Being open to alternative materials can help customers find more cost-effective solutions without sacrificing performance. Customers can work with the manufacturer to identify alternative materials that offer the required performance at a lower cost.

Optimize panelization: Optimizing panelization can help customers maximize the number of flexible PCBs produced in a single manufacturing run, which can help reduce production costs.

Following these tips, customers can work with the manufacturer to minimize costs while receiving high-quality, reliable, flexible PCBs.

Choosing the Right Manufacturer: How to Find a Reliable Flexible PCB Maker

When it comes to choosing a flexible PCB manufacturer, there are several factors that customers should consider to ensure they select a reliable and trustworthy supplier. Here are some tips for choosing the right flexible PCB maker:

- Look for certifications: Certifications like ISO 9001 and UL indicate that the manufacturer has established quality management systems and meets industry standards. These certifications can help customers ensure that the manufacturer is committed to producing high-quality, reliable products.

- Check the manufacturing capabilities: Customers should evaluate the manufacturer’s manufacturing capabilities, including the types of flexible PCBs they produce, their production capacity, and their ability to customize designs. It is also important to consider the manufacturer’s equipment, technology, and production processes to ensure they can deliver consistent, high-quality products.

- Assess the experience and expertise: Customers should consider the manufacturer’s experience and expertise in producing flexible PCBs. They can review the manufacturer’s portfolio, case studies, and customer reviews to evaluate their ability to meet specific requirements and deliver quality products.

- Evaluate customer service: Customer service is essential to any manufacturing relationship. Customers should evaluate the manufacturer’s communication, responsiveness, and willingness to provide support and guidance throughout the process.

- Review the pricing and lead times: Pricing and lead times are critical factors in choosing a flexible PCB manufacturer. Customers should evaluate the manufacturer’s pricing structure, lead times, and any additional fees or charges to ensure they get a fair price for their order.

By considering these factors, customers can find a reliable and trustworthy flexible PCB manufacturer to meet their specific requirements and deliver high-quality, reliable products.

Balancing Price and Quality: Finding the Sweet Spot for Flexible PCBs

When it comes to flexible PCBs, finding the right balance between price and quality is crucial. While customers may be tempted to go for the cheapest option available, low prices may come at the cost of quality and reliability. On the other hand, paying a premium price does not always guarantee the best quality. Here are some tips for finding the sweet spot between price and quality when ordering flexible PCBs:

Define your requirements: Before ordering flexible PCBs, customers should define their requirements regarding performance, functionality, and budget. This will help them identify the right balance between price and quality based on their needs.

Evaluate multiple suppliers: Customers should evaluate flexible PCB suppliers to compare pricing, lead times, and quality. It is important to consider the total cost of ownership, including any additional fees or charges, and the supplier’s experience and reputation.

Consider the long-term benefits: Choosing a supplier based solely on the lowest price may result in hidden costs in the long term, such as product failures, delays, or additional testing and certification expenses. Customers should consider the long-term benefits of working with a reliable supplier that consistently delivers high-quality, reliable products.

Optimize the design: Optimizing the design of the flexible PCB can help reduce costs without compromising quality or performance. Customers can work with the supplier to identify opportunities to simplify the design, minimize waste, and reduce production time and costs.

Negotiate pricing: Customers should negotiate pricing with the supplier based on their requirements, order volume, and delivery schedule. Establishing clear expectations and timelines is important to avoid misunderstandings or disputes.

By finding the sweet spot between price and quality, customers can ensure they get the best value for their money and receive high-quality, reliable, flexible PCBs that meet their specific needs.

JHYPCB's Expertise in Flexible PCB Manufacturing

At JHYPCB, we have over 15 years of experience in manufacturing high-quality flexible PCBs. Our state-of-the-art facilities and skilled team allow us to offer:

- Customized solutions for various industries, including automotive, medical, and consumer electronics

- Quick turnaround times without compromising on quality

- Competitive pricing thanks to our optimized manufacturing processes

- Strict quality control measures, ensuring each PCB meets international standards

Ready to Optimize Your Flexible PCB Costs?

At JHYPCB, we’re committed to providing high-quality flexible PCBs at competitive prices. Our team of experts is ready to help you navigate the complexities of flexible PCB pricing and find the best solution for your project.

Contact us today for a personalized quote or to discuss your flexible PCB needs. Let’s work together to bring your innovative designs to life while optimizing your costs.