Revolutionizing Electronics: The Power of Copper Based PCBs

In the ever-evolving world of electronics, one innovation stands out for its remarkable impact on performance and reliability: copper based PCBs. At JHYPCB, we’re passionate about pushing the boundaries of what’s possible in PCB technology. Today, we’re excited to take you on a journey into the world of copper based PCBs and show you why they’re becoming the backbone of modern electronics.

Imagine a world where your devices run cooler, perform better, and last longer. That’s the promise of copper based PCB technology. Whether you’re developing cutting-edge smartphones, high-powered electric vehicles, or advanced aerospace systems, copper based PCBs are changing the game.

But what exactly are copper based PCBs? How do they differ from traditional PCBs? And why should you care? These are the questions we’ll answer as we explore the fascinating world of copper based PCB manufacturing.

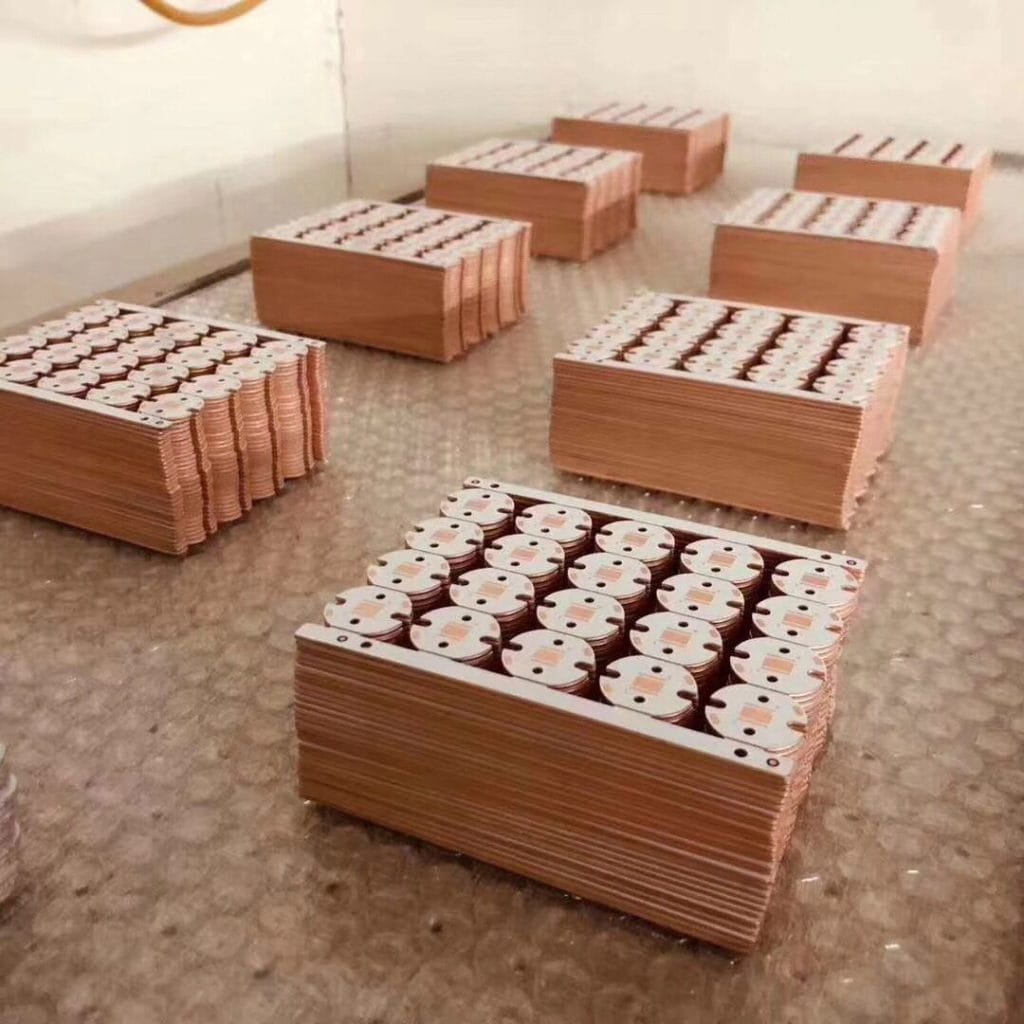

As a leading copper based PCB manufacturer, we at JHYPCB have seen firsthand the transformative power of this technology. From enhancing thermal management in LED lighting to enabling more compact and efficient power electronics, copper based PCBs are at the heart of many technological advancements.

In this article, we’ll demystify copper based PCBs, exploring their unique advantages, diverse applications, and the intricate process behind their manufacture. We’ll also look at why choosing the right copper based PCB manufacturer is crucial for your project’s success.

So, whether you’re an electronics engineer looking for solutions to thermal challenges, a product designer aiming to push the boundaries of what’s possible, or simply a tech enthusiast curious about the latest innovations, this guide is for you.

Ready to discover how copper based PCBs can revolutionize your electronics? Let’s dive in!

The Copper Advantage: Understanding Copper Based PCBs

When you hold a smartphone or use a high-performance computer, you’re experiencing the silent revolution of copper based PCBs. But what sets these PCBs apart from their traditional counterparts? Let’s peel back the layers and explore the unique world of copper based PCB technology.

At its core, a copper based PCB is more than just a circuit board – it’s a marvel of engineering that leverages copper’s exceptional properties to enhance electronic performance. Unlike standard PCBs, copper based variants incorporate a substantial copper layer, either as a core or base, revolutionizing how we manage heat and electrical current in electronic devices.

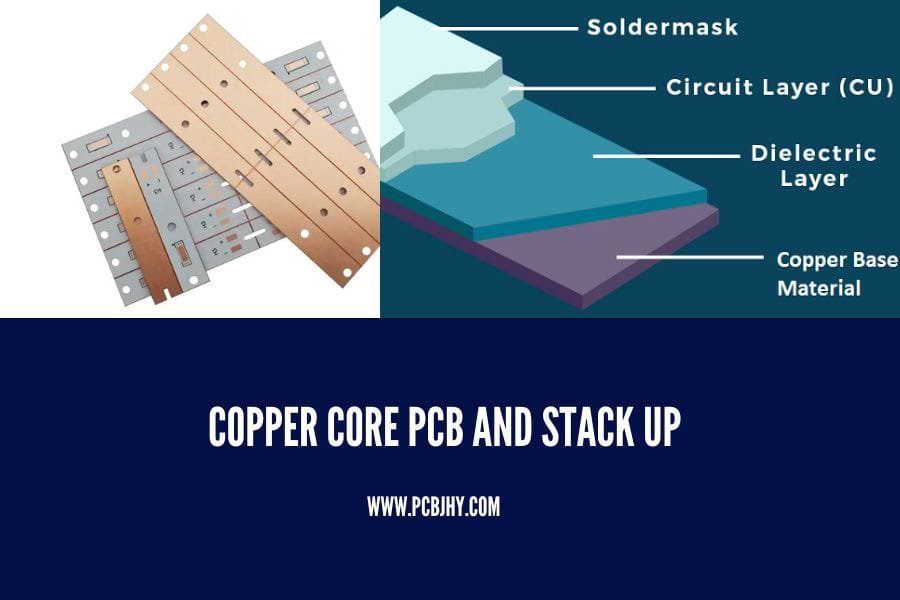

Copper Core vs Copper Base: Two Sides of the Same Coin

In the realm of copper based PCBs, we encounter two main types: copper core and copper base. Think of copper core PCBs as a copper-rich sandwich, with a thick copper layer nestled between traditional PCB layers. This design excels at spreading heat across the entire board, making it ideal for applications where uniform heat distribution is crucial.

On the other hand, copper base PCBs feature a thick copper layer as their foundation. This structure is particularly effective at whisking heat away from specific components, making it a go-to choice for high-power LED modules and other heat-intensive applications.

At JHYPCB, our expertise in metal core PCB manufacturing allows us to produce both types with precision and quality, ensuring we can meet diverse customer needs.

The Copper Difference: Why It Matters

You might wonder, “Why all this fuss about copper?” The answer lies in copper’s unique properties. Its exceptional thermal conductivity allows copper based PCBs to manage heat more effectively than traditional boards. This means your devices can run cooler, potentially extending their lifespan and allowing for more compact designs.

But the benefits don’t stop at heat management. Copper’s superior electrical conductivity enables these PCBs to handle higher currents with less resistance. For power-hungry applications or high-frequency circuits, this can translate to improved efficiency and performance.

Moreover, the robust nature of copper adds a mechanical strength bonus. In applications subject to vibration or frequent temperature changes, copper based PCBs stand strong, offering enhanced durability and reliability.

As we continue to push the boundaries of electronic design, demanding more power in smaller packages, the advantages of copper based PCBs become increasingly apparent. From powering electric vehicles to enabling faster data centers, these advanced PCBs are at the heart of many technological breakthroughs.

In the following sections, we’ll delve deeper into the specific advantages of copper based PCBs and explore the diverse applications where they truly shine. Whether you’re a seasoned engineer or a curious tech enthusiast, understanding copper based PCBs is key to grasping the future of electronics.

Ready to explore how copper based PCBs can elevate your next project? Let’s continue our journey into this fascinating technology!

Advantages of Copper Based PCBs

At JHYPCB, we’re not just manufacturers; we’re innovators who understand the unique benefits that copper based PCBs bring to the table. Let’s explore why these advanced PCBs are becoming the go-to choice for many high-performance applications.

Superior Thermal Management

One of the standout features of copper based PCBs is their exceptional thermal management capabilities. As a leading copper based PCB manufacturer, we’ve seen firsthand how this advantage plays out in real-world applications.

Copper, with its excellent thermal conductivity, allows these PCBs to dissipate heat much more efficiently than traditional boards. This is crucial in today’s world of compact, high-power electronics where thermal management is often a significant challenge. By using copper based PCBs, you can potentially reduce the need for additional cooling systems, leading to more compact and cost-effective designs.

Enhanced Electrical Conductivity

Copper’s superb electrical properties make copper based PCBs a natural choice for applications requiring high current capacity or low impedance. The thick copper layer provides a low-resistance path for electric current, reducing power loss and improving overall efficiency.

This enhanced conductivity is particularly beneficial in power electronics, where copper based PCBs can handle higher currents without overheating. It’s one of the reasons why our customers in the automotive and renewable energy sectors often opt for copper based PCB solutions.

Improved Mechanical Strength

Don’t let the term “printed circuit board” fool you – copper based PCBs are robust pieces of engineering. The copper core or base adds significant structural integrity to the board, making it more resistant to bending and warping.

This improved mechanical strength is especially valuable in applications subject to vibration or thermal cycling. Whether it’s in automotive electronics or industrial machinery, copper based PCBs stand up to the challenge, providing reliability where it matters most.

Longer Lifespan and Reliability

At JHYPCB, we believe in creating products that stand the test of time. Copper based PCBs, with their superior heat dissipation and structural integrity, often boast a longer lifespan than traditional PCBs.

The improved thermal management reduces thermal stress on components, while the mechanical strength helps prevent failure due to physical stress. This combination results in a more reliable product overall, reducing the need for replacements and maintenance.

Moreover, copper’s natural resistance to corrosion adds another layer of durability to these PCBs. In environments where moisture or corrosive substances might be present, copper based PCBs can offer enhanced protection for your circuitry.

It’s worth noting that the benefits of copper based PCBs align well with the industry trends towards miniaturization and increased power density. As highlighted by the IPC’s industry trends report, these factors are becoming increasingly important in electronics manufacturing.

At JHYPCB, we’re committed to staying at the forefront of PCB technology. Our expertise in copper based PCB manufacturing allows us to harness these advantages, providing our customers with cutting-edge solutions that meet the demands of modern electronics.

In the next section, we’ll explore the diverse applications where copper based PCBs truly shine. From high-power electronics to aerospace, you’ll see why more and more industries are turning to this innovative PCB technology. Stay tuned to discover how copper based PCBs might be the perfect solution for your next project!

Applications of Copper Based PCBs

At JHYPCB, we’ve seen copper based PCBs revolutionize various industries. As a leading copper based PCB manufacturer, we’re excited to share how these advanced boards are making a difference across multiple sectors. Let’s explore some key applications where copper based PCBs truly shine.

High-Power Electronics

In the realm of high-power electronics, copper based PCBs are nothing short of a game-changer. Their superior thermal management and high current-carrying capacity make them ideal for applications such as:

- Power supplies

- Motor controllers

- Inverters for solar panels

Our customers in the power electronics sector often praise the reliability and efficiency gains they’ve achieved by switching to copper based PCBs.

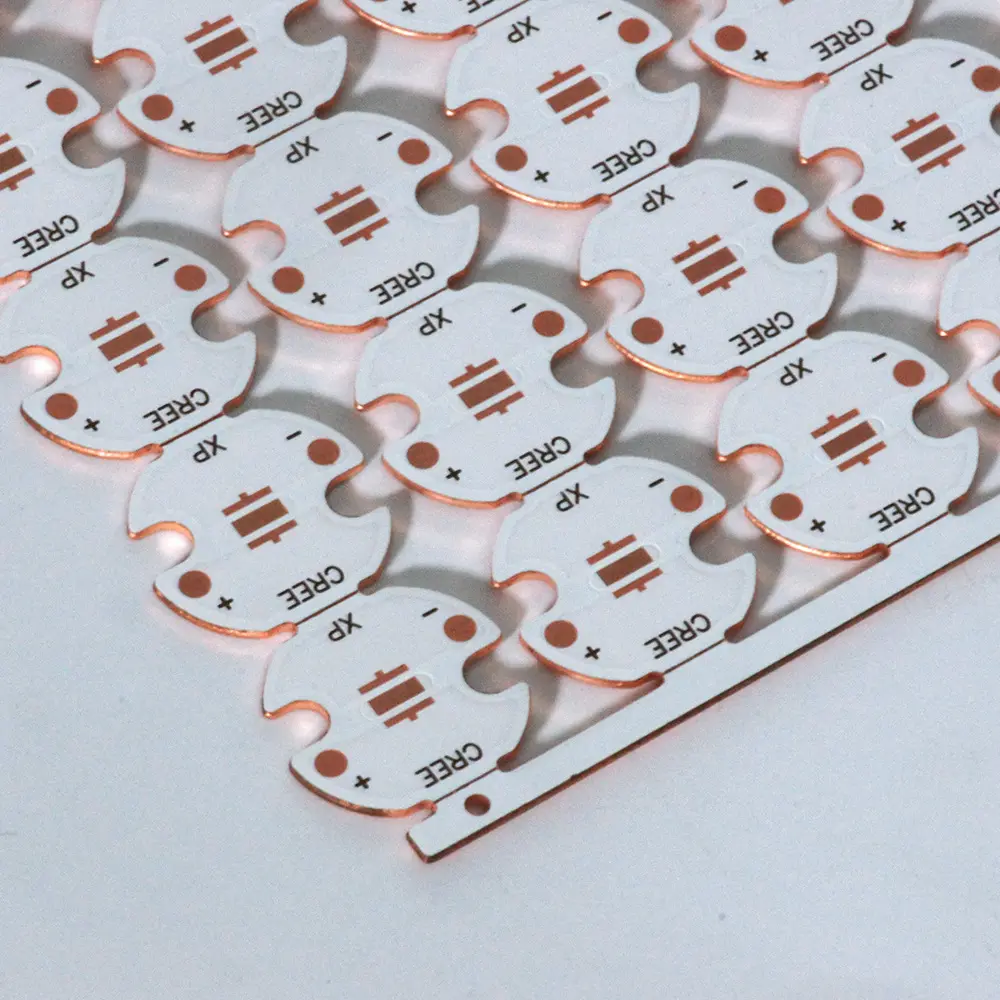

The LED industry has embraced copper based PCBs wholeheartedly, and for good reason. High-brightness LEDs generate significant heat, which can affect their lifespan and performance. Copper based PCBs, particularly copper base PCBs, excel at dissipating this heat, allowing for:

- Brighter and more efficient LED systems

- Longer-lasting LED products

- More compact lighting designs

Our expertise in LED PCB manufacturing has helped numerous lighting companies push the boundaries of what’s possible with LED technology.

The automotive sector is another area where copper based PCBs are making waves. With the increasing electrification of vehicles, the demand for PCBs that can handle high power and withstand harsh environments is soaring. Copper based PCBs find applications in:

- Electric vehicle power systems

- Advanced driver-assistance systems (ADAS)

- Engine control units

The robustness and reliability of copper based PCBs make them a perfect fit for the demanding automotive environment.

Aerospace and Military Applications

When failure is not an option, copper based PCBs step up to the plate. In aerospace and military applications, where performance and reliability are paramount, these PCBs prove their worth. They’re used in:

- Avionics systems

- Radar equipment

- Satellite communications

The ability of copper based PCBs to withstand extreme conditions while delivering top-notch performance makes them a go-to choice for these critical applications.

Renewable Energy Systems

As the world shifts towards sustainable energy, copper based PCBs are playing a crucial role. In solar inverters and wind turbine control systems, these PCBs help maximize energy efficiency and system reliability. Their ability to handle high currents and dissipate heat effectively makes them ideal for:

- Solar power inverters

- Wind turbine pitch control systems

- Energy storage management systems

At JHYPCB, we’re proud to contribute to the green energy revolution through our copper based PCB solutions.

The versatility of copper based PCBs is truly remarkable. From powering your LED lights to controlling spacecraft, these advanced PCBs are pushing the boundaries of what’s possible in electronics design.

As noted by the IPC’s automotive standards, the demands on PCBs in modern applications are higher than ever. Copper based PCBs are rising to meet these challenges, offering a robust solution for a wide range of high-performance applications.

In the next section, we’ll take you behind the scenes and explore the intricate process of manufacturing copper based PCBs. Stay tuned to discover how JHYPCB turns raw materials into high-performance circuit boards that power the technology of tomorrow!

Copper Based PCB Manufacturing Process

At JHYPCB, we take pride in our state-of-the-art manufacturing process for copper based PCBs. As a leading copper based PCB manufacturer, we’ve honed our techniques to ensure the highest quality and performance. Let’s take a behind-the-scenes look at how we bring these advanced PCBs to life.

Step 1. Design Considerations and DFM Check

While JHYPCB doesn’t offer PCB design services, we play a crucial role in ensuring your copper based PCB designs are optimized for manufacturing. Our expertise comes into play through our comprehensive Design for Manufacturing (DFM) check service.

When you submit your PCB design files to us, our team of experienced engineers meticulously reviews them, focusing on several key aspects:

- Thermal management optimization: We assess whether the design effectively utilizes the thermal properties of copper based PCBs.

- Current carrying capacity: Our team verifies if the copper thickness and trace widths are suitable for the intended current loads.

- Manufacturability: We check for any design elements that might pose challenges during the fabrication process.

- Compliance with industry standards: Our DFM check ensures your design aligns with relevant IPC standards for copper based PCBs.

Through this DFM check service, we help identify potential issues early in the process, saving time and resources. If we spot any areas for improvement, we provide detailed feedback and suggestions, allowing you to refine your design for optimal performance and manufacturability.

This collaborative approach ensures that your copper based PCB design is not just theoretically sound, but also practical to manufacture at the highest quality standards. It’s our way of combining your innovative designs with our manufacturing expertise to create superior copper based PCBs.

By offering this valuable DFM check service, we at JHYPCB aim to bridge the gap between design and manufacturing, helping you bring your copper based PCB projects to life efficiently and effectively.

Step 2. Material Selection

Choosing the right materials is paramount in copper based PCB manufacturing. The copper layer, of course, is the star of the show, but other materials play crucial supporting roles:

- High-quality copper foil or plate for the core or base

- Thermally conductive dielectric materials

- Appropriate laminate materials for outer layers

We source our materials from trusted suppliers to ensure consistency and quality in every copper based PCB we produce.

Step 3. Fabrication Techniques

The fabrication of copper based PCBs requires specialized techniques and equipment. Our process typically includes:

- Copper layer preparation: For copper core PCBs, we start by preparing the thick copper layer that will form the core. For copper base PCBs, we begin with a solid copper plate.

- Lamination: We use high-pressure, high-temperature lamination processes to bond the copper layer with the outer PCB layers.

- Drilling and plating: Precision drilling is followed by plating to create the necessary connections between layers.

- Etching and patterning: We use advanced etching techniques to create the circuit patterns on the outer layers.

- Surface finishing: Depending on the specific requirements, we apply appropriate surface finishes to protect the copper and enhance solderability.

Our PCB fabrication process is continually refined to keep up with the latest industry standards and technological advancements.

Step 4. Quality Control Measures

At JHYPCB, quality is not just a buzzword – it’s a commitment. Our copper based PCB manufacturing process includes rigorous quality control measures at every stage:

- Incoming material inspection

- In-process checks during fabrication

- Electrical testing of finished boards

- Thermal and mechanical stress testing for high-reliability applications

We adhere to strict IPC standards and employ advanced inspection technologies, including Automated Optical Inspection (AOI) and X-ray inspection for multi-layer boards.

Our commitment to quality extends beyond the production floor. We maintain a clean, controlled environment in our manufacturing facilities to prevent contamination and ensure consistent results.

Manufacturing copper based PCBs is a complex process that requires expertise, precision, and attention to detail. At JHYPCB, we’ve invested heavily in technology and training to ensure we can meet the most demanding requirements for copper based PCBs.

Whether you need a copper core PCB for a high-power application or a copper base PCB for an advanced LED lighting system, our manufacturing process is designed to deliver PCBs that meet and exceed your expectations.

In the next section, we’ll highlight why JHYPCB stands out as your trusted partner for copper based PCB manufacturing. Stay tuned to learn about our unique capabilities and how we can support your next project!

JHYPCB: Your Trusted Copper Based PCB Manufacturer

When it comes to copper based PCBs, experience and expertise matter. At JHYPCB, we’ve established ourselves as a leading copper based PCB manufacturer, combining cutting-edge technology with years of industry knowledge. Let’s explore why we’re the partner of choice for your copper based PCB needs.

Our Expertise and Experience

With over a decade in the PCB industry, JHYPCB has honed its skills in copper based PCB manufacturing. Our team of engineers and technicians bring a wealth of experience to every project:

- Specialized knowledge in copper core PCB and copper base PCB design

- Proven track record in high-reliability PCB manufacturing

- Continuous training and development to stay ahead of industry trends

Our expertise extends beyond just manufacturing. We offer comprehensive PCB assembly services, ensuring a seamless transition from bare board to finished product.

Advanced Manufacturing Capabilities

At JHYPCB, we invest heavily in state-of-the-art equipment and processes to deliver the highest quality copper based PCBs:

- Advanced lamination presses for optimal copper bonding

- Precision drilling and routing equipment for complex designs

- High-resolution imaging systems for fine line and space capabilities

- Automated testing equipment for thorough quality assurance

Our manufacturing capabilities allow us to handle a wide range of copper based PCB projects, from prototype runs to high-volume production.

Quality Assurance and Certifications

Quality is at the heart of everything we do at JHYPCB. Our commitment to excellence is reflected in our rigorous quality control processes and industry certifications:

- ISO 9001:2015 certified quality management system

- UL certification for safety-critical applications

- RoHS and REACH compliance for environmental responsibility

- IPC-A-600 Class 2 and Class 3 capabilities for high-reliability PCBs

We also maintain partnerships with leading industry organizations, keeping us at the forefront of PCB manufacturing standards and best practices.

Custom Solutions and Support Services

At JHYPCB, we understand that every copper based PCB project is unique. That’s why we offer customized solutions tailored to your specific needs:

- Collaborative design support to optimize your copper based PCB layout

- Material selection guidance for optimal performance and cost-efficiency

- Prototyping services for rapid design validation

- Flexible production scheduling to meet your time-to-market requirements

Our customer support doesn’t end with delivery. We provide comprehensive after-sales support, ensuring your copper based PCBs perform as expected in your application.

As a trusted copper based PCB manufacturer, we’re committed to your success. Whether you’re developing cutting-edge power electronics, advanced LED lighting systems, or next-generation automotive components, JHYPCB has the expertise and capabilities to bring your ideas to life.

Don’t just take our word for it. Our customer testimonials speak volumes about our commitment to quality and customer satisfaction. We’ve helped numerous companies across various industries leverage the power of copper based PCBs to innovate and excel in their respective fields.

In an industry where precision and reliability are paramount, JHYPCB stands out as a copper based PCB manufacturer you can trust. Our combination of technical expertise, advanced manufacturing capabilities, and unwavering commitment to quality makes us the ideal partner for your copper based PCB projects.

Ready to take your electronic designs to the next level with copper based PCBs? In the next section, we’ll guide you through the process of choosing the right copper based PCB for your project and how to get started with JHYPCB. Stay tuned to learn how we can help turn your innovative ideas into reality!

Choosing the Right Copper Based PCB for Your Project

As a leading copper based PCB manufacturer, JHYPCB understands that selecting the right PCB is crucial for your project’s success. Let’s explore the key factors to consider when choosing a copper based PCB and how working with an experienced manufacturer can make all the difference.

Factors to Consider

When deciding on a copper based PCB for your application, several factors come into play:

- Thermal Requirements: Consider the heat dissipation needs of your application. High-power electronics or LED lighting systems might benefit more from a copper base PCB, while applications requiring uniform heat spreading might be better served by a copper core PCB.

- Current Carrying Capacity: Evaluate the current requirements of your circuit. Copper based PCBs excel in high-current applications, but the specific design will depend on your exact needs.

- Mechanical Stress: If your application involves vibration or frequent thermal cycling, the enhanced mechanical strength of copper based PCBs can be a significant advantage.

- Size and Weight Constraints: Copper based PCBs can often allow for more compact designs due to their superior thermal management, but they may be heavier than traditional PCBs.

- Environmental Conditions: Consider factors like humidity, temperature extremes, or exposure to corrosive substances in your operating environment.

Our PCB capabilities page provides more detailed information on these considerations and how they relate to different types of copper based PCBs.

Working with a Manufacturer

Partnering with an experienced copper based PCB manufacturer like JHYPCB can significantly streamline your design and production process:

- Design Consultation: Our engineers can review your design and suggest optimizations specific to copper based PCB technology.

- Material Selection: We can help you choose the most appropriate materials based on your performance requirements and budget constraints.

- Prototyping: Our rapid prototyping services allow you to test and refine your design before committing to full production.

- Quality Assurance: Our rigorous testing procedures ensure that your copper based PCBs meet the highest quality standards.

- Production Flexibility: Whether you need a small batch for a specialized application or high-volume production, we can accommodate your needs.

Cost Considerations and ROI

While copper based PCBs may have a higher initial cost compared to traditional PCBs, it’s important to consider the long-term return on investment:

- Improved Performance: The superior thermal and electrical properties of copper based PCBs can lead to better overall system performance.

- Increased Reliability: The enhanced durability of copper based PCBs can reduce failure rates and extend the lifespan of your products.

- Simplified Thermal Management: In many cases, copper based PCBs can reduce or eliminate the need for additional cooling systems, potentially lowering overall system costs.

- Space Savings: The ability to design more compact systems with copper based PCBs can lead to material savings in other areas of your product.

At JHYPCB, we’re committed to helping you find the most cost-effective solution that meets your performance requirements. Our team can provide detailed cost analysis and ROI projections to help you make an informed decision.

Choosing the right copper based PCB is a critical step in your product development process. As your trusted copper based PCB manufacturer, JHYPCB is here to guide you through every step of the journey. From initial design consultation to final production, we’re committed to delivering copper based PCBs that exceed your expectations.

Ready to take the next step? Visit our contact page to discuss your copper based PCB needs with our experts. Let’s work together to bring your innovative designs to life with the power of copper based PCB technology!

In the final section, we’ll explore the future trends in copper based PCB technology and how JHYPCB is staying ahead of the curve. Stay tuned to discover what’s on the horizon for this exciting field!

Future Trends in Copper Based PCB Technology

As a forward-thinking copper based PCB manufacturer, JHYPCB is always keeping an eye on the horizon. The world of electronics is evolving rapidly, and with it, the technology behind copper based PCBs. Let’s explore some exciting trends and developments that are shaping the future of this innovative field.

Emerging Applications

Copper based PCBs are finding their way into increasingly diverse and cutting-edge applications:

- 5G Infrastructure: The high-frequency, high-power demands of 5G technology make copper based PCBs an ideal choice for base stations and other network equipment.

- Electric Vehicles: As the automotive industry continues its electric revolution, copper based PCBs are becoming crucial for power management and battery systems.

- Artificial Intelligence and Machine Learning: The intensive computing power required for AI and ML applications often generates significant heat, making copper based PCBs an attractive solution for thermal management.

- Internet of Things (IoT) Devices: As IoT devices become more powerful and compact, copper based PCBs offer a way to manage increased power density in smaller form factors.

At JHYPCB, we’re excited to be at the forefront of these emerging applications, constantly refining our PCB manufacturing processes to meet new challenges.

Technological Advancements

The field of copper based PCB technology is not standing still. Several advancements are pushing the boundaries of what’s possible:

- Ultra-Thin Copper Cores: Manufacturers are developing techniques to produce ever-thinner copper cores, allowing for more layers in multi-layer designs without increasing overall board thickness.

- Advanced Copper Plating Techniques: New plating methods are being explored to enhance the electrical and thermal properties of copper based PCBs even further.

- Hybrid Materials: Research is ongoing into combining copper with other materials like graphene or carbon nanotubes to create PCBs with even better thermal and electrical properties.

- 3D Printing: While still in its early stages, 3D printing technology holds promise for creating complex copper based PCB structures that are difficult to achieve with traditional manufacturing methods.

As a leading copper based PCB manufacturer, JHYPCB is actively investing in research and development to stay ahead of these technological trends.

Sustainability and Environmental Considerations

The electronics industry is increasingly focusing on sustainability, and copper based PCB technology is no exception:

- Recycling Initiatives: New methods are being developed to more efficiently recycle copper from PCBs, reducing waste and conserving resources.

- Energy Efficiency: The superior thermal management of copper based PCBs can contribute to overall system energy efficiency, aligning with global efforts to reduce energy consumption.

- Eco-Friendly Manufacturing: The PCB industry is exploring more environmentally friendly manufacturing processes, including the use of less harmful chemicals and reduced water consumption.

At JHYPCB, we’re committed to sustainable practices in our copper based PCB manufacturing processes. Our quality control measures not only ensure top-notch products but also minimize waste and environmental impact.

The future of copper based PCB technology is bright and full of possibilities. As these trends continue to evolve, they will open up new opportunities for innovation across various industries. At JHYPCB, we’re excited to be part of this journey, continuously adapting our copper based PCB manufacturing capabilities to meet the changing needs of our clients and the electronics industry as a whole.

Staying ahead in this dynamic field requires a partner who is not just reactive, but proactive. As your trusted copper based PCB manufacturer, JHYPCB is committed to being that partner. We’re constantly investing in new technologies, refining our processes, and expanding our expertise to ensure we can meet your copper based PCB needs both now and in the future.

Ready to embrace the future of PCB technology? Contact JHYPCB today to discuss how our advanced copper based PCB solutions can power your next-generation electronic designs. Let’s innovate together!

Conclusion

Throughout this article, we’ve delved deep into the world of copper based PCBs, exploring their unique advantages and wide-ranging applications. As a leading copper based PCB manufacturer, JHYPCB is at the forefront of this innovative technology.

Copper based PCBs have emerged as a game-changer in the electronics industry. Their superior thermal management and excellent electrical conductivity make them the go-to choice for high-power and high-frequency applications. From automotive to aerospace, these advanced PCBs are revolutionizing various sectors with their enhanced performance and reliability.

The manufacturing process for copper based PCBs is no simple feat. It requires specialized expertise and advanced equipment – areas where JHYPCB excels. Our commitment to quality and innovation ensures that we deliver copper based PCBs that meet and exceed the most demanding requirements.

As we look to the future, the importance of copper based PCBs in electronics cannot be overstated. As devices become more powerful and compact, the thermal management and high current handling capabilities of copper based PCBs will become increasingly crucial. At JHYPCB, we’re ready to meet these future challenges head-on.

Are you ready to harness the power of copper based PCBs for your next project? As your trusted partner in copper based PCB manufacturing, JHYPCB offers expert design consultation, state-of-the-art manufacturing capabilities, rigorous quality control, and flexible production options.

Don’t let thermal management or high-current challenges hold back your innovative designs. Contact JHYPCB today to discuss how our copper based PCB solutions can elevate your electronics to the next level. Visit our contact page or call us to begin your copper based PCB journey. The future of electronics is here – let’s build it together!

Related Posts

- What is IMS PCB? A Guide to Insulated Metal Substrate PCBs

- The Best Materials for LED PCB Boards

- Aluminum PCBs: The Optimal Thermal Solution for High-Power Electronics

- Applications of Aluminum PCB: A Comprehensive Overview

- The Ultimate Guide to Aluminum PCB Manufacturing Process

- The Importance of Choosing the Right Aluminum PCB Manufacturer

- An Introduction to Aluminum Substrate PCB Types

- A Comparison of Aluminum Core PCBs and Copper Core PCBs

- Comparative Analysis of Aluminum PCB and FR-4 PCB

- The Specialized Manufacturing Process for Heavy Copper PCBs

- Why is copper used in PCB?

- How to Design a Heavy Copper PCB?

- Heavy Copper PCBs: Unlocking Higher Currents and Better Thermal Management

- Advantages and Applications of Heavy Copper PCBs over Conventional PCBs

- Complete Guide for PCB Material