Your Premier LED PCB Manufacturer in China

JHYPCB is a leading LED PCB manufacturer and assembler in China. With over 15 years of experience in the PCB industry, we have the expertise and capability to deliver high-quality LED PCB solutions.

Headquartered in Shenzhen, the heart of electronics manufacturing in China, JHYPCB leverages the supply chain and engineering infrastructure to provide cost-effective and reliable LED PCB fabrication and assembly services.

As one of the top LED PCB companies in China, JHYPCB has a huge production facility with SMT lines from renowned manufacturers like Fuji, Yamaha, and Juki. This allows us to manufacture LED PCBs in high volume.

We fully comply with quality standards such as ISO 9001, ISO 14001, QC 080000, and TS 16949. This highlights our commitment to meeting the highest quality benchmarks.

JHYPCB has a strong R&D team that keeps us ahead of the technology curve. We invest heavily in developing solutions tailored specifically for LED applications.

With abundant experience in servicing global customers from Europe, America, and Asia, we can meet the strict demands and standards of the electronics industry worldwide.

If you are looking for a reliable Chinese company to partner with for your LED PCB needs, look no further than JHYPCB. Get in touch with us today to learn more.

Advanced Manufacturing Technologies of a Leading LED PCB Manufacturer

At JHYPCB, we utilize cutting-edge technologies and processes to manufacture high-quality LED PCBs. Our extensive capabilities ensure efficiency, precision, and reliability throughout the fabrication and assembly process.

Our SMT production lines are equipped with Yamaha YSM10 high-speed mounters capable of placing 01005 components. These are supplemented by Fuji NXT IIIPlacement Machines for flexible mixed-line production. We also utilize Juki high-accuracy wire bonders and die bonders for excellent precision.

For inspection, we have Koh Young Zenith 3D AOI systems that perform multi-angle checks on assembled PCBs. Our testing capabilities include flying probe testing for bare boards and ICT for assembled PCBs.

All our manufacturing equipment is linked to a central ERP system. This enables excellent traceability and quality control across the entire production floor.

We continuously invest in upgrading our manufacturing technologies. Our R&D team focuses on implementing solutions tailored for LED PCBs, such as thermal management capabilities.

With our heavy investments in advanced equipment and processes, JHYPCB can deliver exceptional quality standards for LED PCB fabrication and assembly, providing great value to customers worldwide.

Complete LED PCB Assembly Services Offered by JHYPCB Manufacturer

At JHYPCB, we offer full assembly services for LED PCBs, complementing our fabrication capabilities. Our assembly technicians are highly trained and experienced in SMT and thru-hole assembly of LED boards.

We assemble boards using components sourced from trusted suppliers like Cree, Nichia, Lumileds, and Samsung. Our enterprise resource planning (ERP) system ensures all component inventory is managed efficiently.

JHYPCB provides value-added services, including design for manufacturing (DFM), component sourcing, supplier quality control, and component engineering. This enables us to optimize the assembly process.

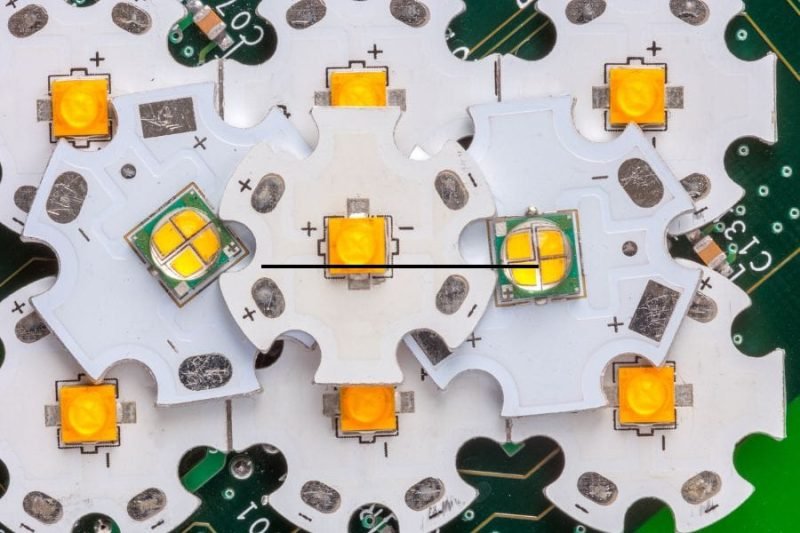

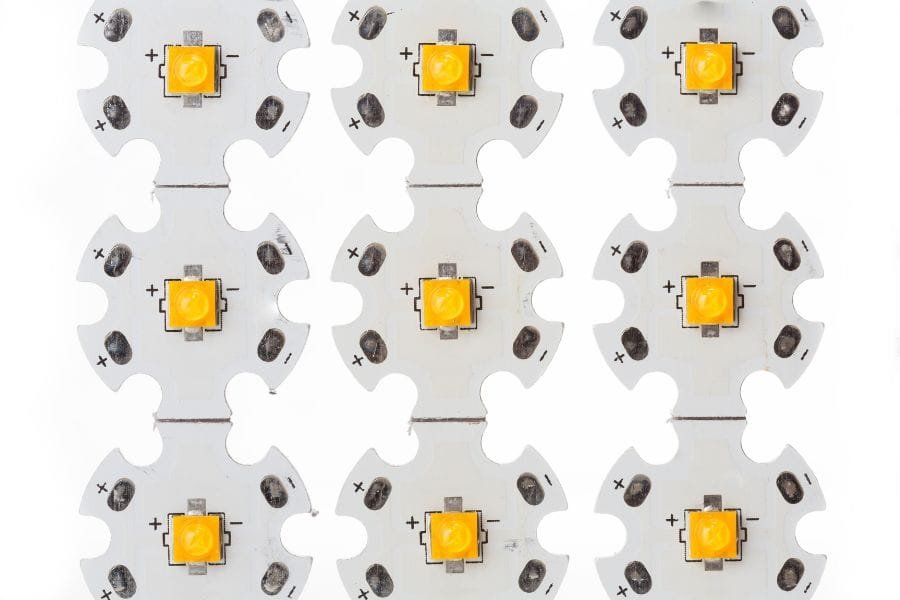

Our assembly lines can handle large board sizes of up to 610mm x 460mm and fine component sizes down to 01005 chips. We can work with various LED packaging types, such as COB, SMD, and modules.

Our automated optical inspection (AOI) and testing capabilities ensure that all assembled PCBs meet quality and functionality requirements before shipment.

For quick-turn prototyping needs, we offer 3-5 day assembly timelines on low-volume orders. High-mix production with rapid changeovers is also possible with our flexible lines.

By leveraging JHYPCB’s expertise in LED PCB fabrication and our assembly services, customers can benefit from a high-quality, one-stop solution for their LED board needs.

Stringent Quality Control as an LED PCB Manufacturer

At JHYPCB, quality is our top priority. We have stringent quality control systems in place to ensure our LED PCBs meet the highest standards.

Our quality management system is ISO 9001 and ISO 14001 certified. This demonstrates our commitment to maintaining excellent quality benchmarks.

We perform 100% automated optical inspection on all PCBs fabricated and assembled. This allows us to catch any defects after major production stages.

Our defect rates are consistently maintained below 100 PPM, reflecting our rigorous quality process controls. All our equipment undergoes scheduled calibration to ensure precision.

We obtain materials and components only from qualified suppliers who pass our strict evaluation criteria. This provides quality upstream in our supply chain.

Our quality engineers collaborate closely with customers during product development. We conduct design and process reviews to optimize manufacturability before production.

Our quality documentation is transparent and accessible to customers through our customer portal. Real-time production monitoring is available.

Through investments in quality personnel, stringent process controls, and customer collaboration, JHYPCB can deliver zero-defect LED PCB solutions that exceed customer expectations.

Custom LED PCB Manufacturing Capabilities

JHYPCB provides exceptional support for customers requiring custom and low-volume LED PCB production. Our flexible manufacturing capabilities allow us to produce PCBs optimized for your application needs.

For custom designs, our engineers provide value-added services, including DFM analysis, component engineering, and technical consultation. This ensures your PCBs can be produced right the first time.

We can manufacture LED PCBs in low volumes, making us ideal for prototyping and small batch requirements. Our production lines have fast changeover times, allowing high-mix production.

Our fabrication lines can handle board sizes up to 610mm x 460mm and thin materials down to 0.4mm thickness. Various stack-up configurations are possible. This gives you design flexibility.

For assembly, we can support LED packaging types like COB, SMD, and modules in small quantities. Quickturns in 3-5 days are possible.

Whether you need short prototype runs, pilot builds, or fluctuating production quantities, JHYPCB can deliver.

R&D and Innovation as an LED PCB Manufacturer

At JHYPCB, we maintain a strong culture of R&D and technology innovation in order to improve our LED PCB solutions continuously.

Our experienced engineering team closely tracks emerging LED technology and market trends. We use these insights to guide targeted improvements in our fabrication and assembly processes.

We collaborate closely with partners in the LED supply chain. This allows us to develop PCB solutions optimized for new LED packaging types and applications as they are released.

Our investments in advanced equipment for inspection, testing, and automation are aimed at boosting quality, precision, and capabilities for LED PCB production.

We have an extensive knowledge base on LED thermal management. Our R&D team focuses on enhancing PCB thermal dissipation capabilities through design innovations.

We develop proprietary process techniques tailored specifically to manufacture high-density and high-power LED PCBs. This provides process reliability and product longevity.

Through sustained R&D and close partnerships within the LED ecosystem, JHYPCB can deliver cutting-edge and high-performance solutions to enable the latest LED applications.

Cost and Delivery Advantages of a China LED PCB Manufacturer

As a leading Chinese PCB manufacturer, JHYPCB is able to provide very cost-competitive solutions without compromising on quality.

By leveraging China’s electronics supply chain and engineering infrastructure, we can procure materials and components at lower costs compared to Western suppliers.

Our large-scale production capabilities and optimized facilities further drive down operating costs. These savings directly benefit customers through lower PCB pricing.

Our location allows us to offer logistical advantages and fast delivery to Asia-based customers. Air/sea shipping enables global delivery within days.

We have real-time visibility of production loading across our multiple SMT lines. This allows us to commit to reliable and aggressive delivery timelines.

Whether you need short-run prototypes or high-volume production, JHYPCB has the capacity and capabilities to deliver quality solutions on time and on budget.

Contact us with your price and lead time requirements. We are confident we can meet your expectations.

Excellent Customer Service as an LED PCB Manufacturer

At JHYPCB, we strive to provide exceptional customer service and technical support throughout your PCB fabrication and assembly process.

Our engineering team offers DFM analysis on new designs to optimize them for production. We also provide PCB design services if required.

We assign dedicated account managers to each customer. They closely monitor your projects and provide timely responses and updates.

Our customer service team can support you across multiple time zones in English, Chinese, and other languages. Technical support engineers can answer queries on production quality or assembly processes.

With JHYPCB as your LED PCB partner, you get start-to-finish support combining technical expertise with responsive customer service. Contact us today to experience the difference.

Why Choose JHYPCB as Your LED PCB Manufacturer

In conclusion, JHYPCB is the premier LED PCB manufacturing partner for customers seeking a high-quality, one-stop solution provider.

With over 15 years of experience, we offer unmatched expertise in the fabrication and assembly of LED circuit boards. Our advanced manufacturing technologies and stringent quality systems enable us to deliver zero-defect products consistently.

Leveraging our location in China, we can produce customizable LED PCB solutions at competitive costs without compromising on quality or lead times.

Our strong R&D culture and close collaboration within the LED supply chain ensure we stay ahead of the latest technologies and market demands.

With excellent customer service through our technical and sales teams, JHYPCB aims to provide a seamless production experience right from design to delivery.

For your next LED PCB project, partner with the leading experts at JHYPCB. Get in touch with us today to learn more about our capabilities. We look forward to delivering excellence for your needs.