With the increasing demand for high-performance and miniaturized electronic devices in today’s market, rigid-flex PCBs have become increasingly popular. In this article, we will explore the benefits and advantages of rigid-flex PCBs.

What are Rigid-Flex PCBs?

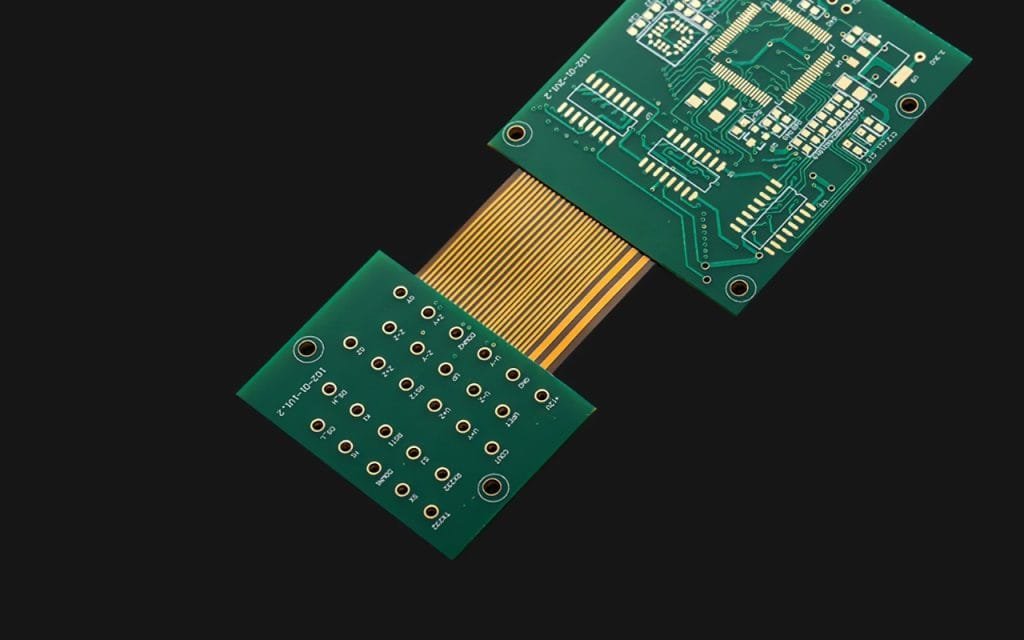

Rigid-flex PCBs are a type of circuit board that combines rigid and flexible board technologies in a single design. These boards are made up of multiple layers of flexible PCB material and rigid PCB material, which are laminated together to create a single board that can bend and flex to some extent.

Rigid-flex PCBs offer a number of advantages over traditional rigid PCBs, including increased flexibility, reduced space requirements, improved reliability, and reduced assembly time. In the following sections, we will explore each of these benefits in more detail.

Benefits of Rigid-Flex PCBs

- Flexibility

One of the main benefits of rigid-flex PCBs is their flexibility. Because they are made up of flexible and rigid materials, they can be designed to fit a wide range of shapes and sizes, making them ideal for various applications.

For example, rigid-flex PCBs are often used in medical devices, where they can be designed to fit into small spaces and conform to complex shapes. They are also used in automotive and aerospace applications, where they can be designed to fit into tight spaces and withstand harsh environmental conditions.

- Space Savings

Another advantage of rigid-flex PCBs is that they can save space in electronic devices. Because they can be designed to fit into tight spaces, they can reduce the overall size of a device, making it more compact and portable.

In addition, rigid-flex PCBs can provide more three-dimensional space for components, improving the device’s overall functionality.

- Reliability

Rigid-flex PCBs offer improved reliability over traditional rigid PCBs. They are less likely to fail or break because they have fewer connection points and joints. In addition, the flexible portion of the board can absorb shocks and vibrations, reducing the risk of damage to the board and its components.

- Reduced Assembly Time

Finally, rigid-flex PCBs can reduce assembly time and simplify the manufacturing process. Because they can be designed to fit into a single board, they eliminate the need for multiple rigid PCBs and connectors. This can reduce the time and labor required to assemble a device and reduce the risk of errors.

Applications

Rigid-flex PCBs are used in a wide range of applications, including:

Medical Devices: Rigid-flex PCBs are often used in medical devices because of their flexibility and reliability. They can be designed to fit into small spaces and withstand harsh environments.

Automotive and Aerospace: Rigid-flex PCBs are also used in automotive and aerospace applications, where they can withstand the extreme temperatures, vibrations, and shocks of these environments.

Consumer Electronics: Rigid-flex PCBs are increasingly being used in consumer electronics, such as smartphones and wearables, where they can save space and improve functionality.

Learn More: The Versatility and Applications of Rigid-Flex PCBs

Manufacturing Process

The manufacturing process for rigid-flex PCBs is more complex than that for traditional rigid PCBs. There are several methods for manufacturing rigid-flex PCBs, including:

Pre-curing Lamination: In this method, the flexible PCB layers are laminated together and then cured before the rigid layers are added. This ensures that the flexible layers retain their shape and do not deform during the lamination process.

Post-curing Lamination: In this method, the flexible and rigid layers are laminated together and then cured as a single unit. This can reduce the overall manufacturing time and cost.

Conclusion

In conclusion, rigid-flex PCBs offer a number of benefits and advantages over traditional rigid PCB boards. They offer increased flexibility, reduced space requirements, improved reliability, and reduced assembly time. They are used in a wide range of applications, including medical devices, automotive and aerospace, and consumer electronics. The manufacturing process for rigid-flex PCBs is more complex than that for traditional rigid PCBs, but it offers a number of advantages for the design and production of electronic devices.

As the demand for high-performance and miniaturized electronic devices continues to grow, rigid-flex PCBs will become increasingly important in the design and production of these devices. With their unique combination of flexibility and reliability, they offer a range of benefits that traditional rigid PCBs cannot match.