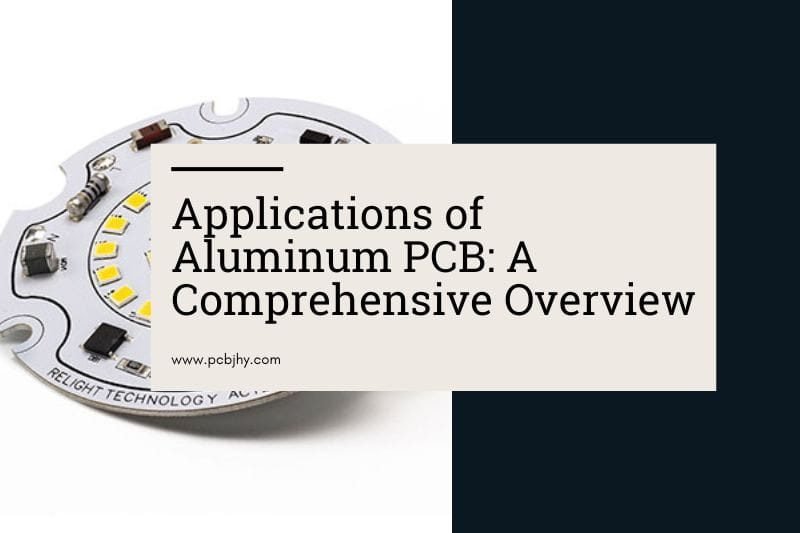

In recent years, aluminum PCBs (Printed Circuit Boards) have gained immense popularity due to their excellent thermal conductivity, heat dissipation capabilities, lightweight, and thin construction. These advantageous properties make aluminum PCBs an ideal choice for high-power electronic applications such as LED lighting systems, power modules, and automotive electronics. This comprehensive article provides an in-depth overview of the diverse applications of aluminum PCBs across the electronics industry. Additionally, it explores the numerous benefits of utilizing aluminum PCBs, critical design considerations, and their environmental impact and sustainability aspects. By the end, you will gain a profound understanding of the pivotal role aluminum PCBs play in advancing sustainable and efficient technology within the electronics sector.

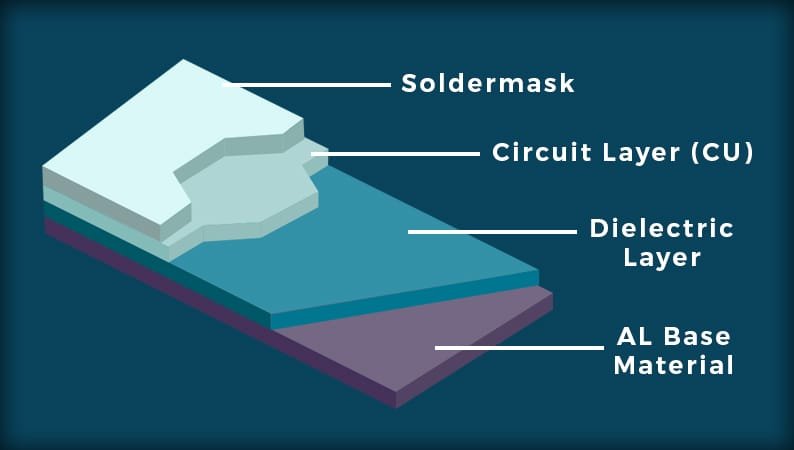

What is an Aluminum PCB?

An aluminum printed circuit board (Al-PCB) is a type of metal-core PCB that consists of a thin layer of thermally conductive dielectric material, such as aluminum oxide or silicon carbide, sandwiched between a copper circuit layer and an aluminum substrate. This unique construction provides exceptional heat dissipation and thermal management capabilities, making aluminum PCBs the preferred choice for high-power electronic applications. They are widely utilized in LED lighting systems, power modules, automotive electronics, and other industries where efficient heat management is crucial. Additionally, aluminum PCBs are known for their lightweight and slim construction, making them suitable for space-constrained applications.

Why are Aluminum PCBs Crucial for Electronics?

The electronics realm has witnessed rapid evolution, driving an ever-increasing demand for powerful and efficient devices. In this landscape, aluminum PCBs have emerged as a pivotal solution, their importance amplified by the industry’s pressing needs. Here’s why these innovative boards have become indispensable:

- Thermal Mastery: Heat dissipation is the Achilles’ heel of high-power electronics. Aluminum PCBs, with their exceptional thermal conductivity, effortlessly tackle this challenge. From LED lighting to power modules and automotive systems, these boards ensure optimal performance by keeping components cool under immense heat.

- High-Power Prowess: The unparalleled thermal management of aluminum PCBs allows them to handle even the most power-hungry applications with ease. This capability unlocks new realms of power density and efficiency for electronic devices.

- Lightweight and Compact: Boasting a slim, lightweight construction, aluminum PCBs are the ideal choice for space-constrained designs. Their sleek profiles facilitate efficient heat transfer while occupying minimal real estate.

- Rugged Durability: These boards are built to withstand thermal stress, ensuring longevity and unwavering reliability – critical qualities for harsh environments and demanding applications.

- Cost-Effectiveness: Compared to other metal-core PCBs, aluminum variants offer a cost-effective solution without compromising performance, appealing to manufacturers focused on optimizing expenses.

As electronics continue to push boundaries, the unique attributes of aluminum PCBs position them as catalysts, driving innovation while upholding sustainability and efficiency standards.

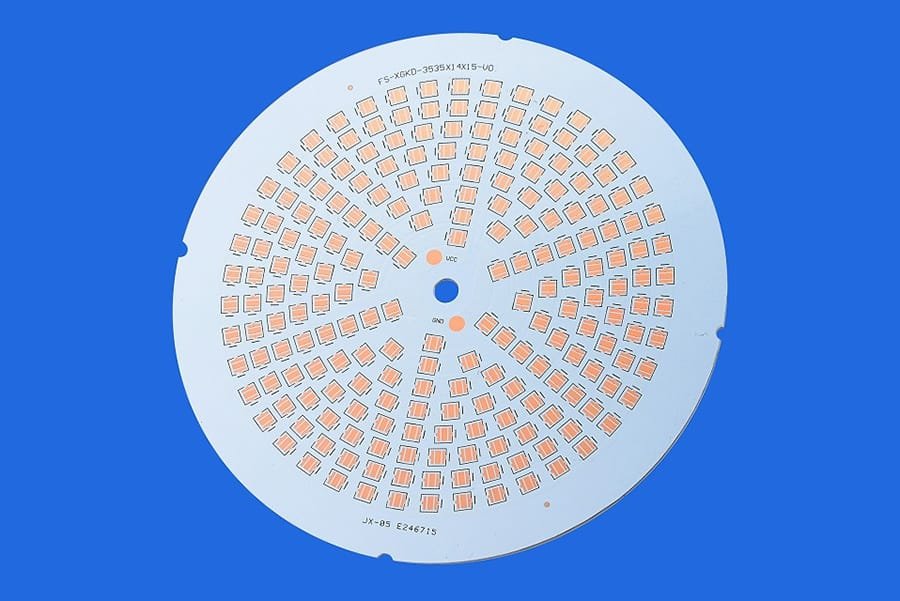

Aluminum PCBs in LED Lighting

LED lighting has ushered in a revolution, offering unparalleled energy efficiency, longevity, and remarkable heat management. At the heart of this transformation lies the aluminum PCB – a critical component that enables LED systems to shine brighter than ever before.

In residential settings, LED bulbs have replaced traditional incandescent lamps, providing homeowners with energy savings and reduced maintenance costs. Their applications extend to accent lighting, under-cabinet illumination, and decorative lighting solutions that elevate any living space.

Outdoor environments have also embraced the LED revolution. Streetlights and floodlights powered by aluminum PCBs deliver brilliant illumination while minimizing energy consumption and maintenance requirements, making our cities more sustainable and cost-effective.

The automotive industry has also harnessed the power of LED lighting, integrating it into headlights, taillights, and interior cabin lighting. Aluminum PCBs ensure precise beam patterns and thermal management, enhancing visibility and safety on the roads.

Industrial facilities and warehouses have found a reliable ally in LED lighting systems. Powered by aluminum PCBs, these energy-efficient luminaires provide superior illumination, reducing operating costs and creating a more productive work environment.

In retail and display applications, LED lighting showcases products in their true colors, captivating customers and creating an immersive shopping experience. Museums and galleries also benefit from LED’s ability to highlight exhibits with precision and vibrancy.

Underpinning all these applications is the aluminum PCB – a unifying force that enables LED lighting to shine brighter, more efficiently, and more sustainably, illuminating the path towards a greener, more energy-conscious future.

Helpful Resouces: PCBS FOR THE LED LIGHTING INDUSTRY

Aluminum PCBs at the Heart of Power Modules

In the ever-evolving world of electronics, power modules stand as the unsung heroes, efficiently converting and controlling electrical energy to fuel our devices. However, managing the intense heat generated by these components is a formidable challenge – one that aluminum PCBs elegantly overcome.

Insulated Gate Bipolar Transistor (IGBT) modules, widely employed in motor drives, power supplies, and renewable energy systems, rely on aluminum PCBs as their robust foundation. These advanced boards dissipate heat with remarkable efficiency, ensuring reliable performance even under the most demanding conditions.

Power supply modules, tasked with converting AC to DC power, benefit immensely from the thermal management prowess of aluminum PCBs. By keeping components cool, these boards enable stable and uninterrupted power delivery to our electronic devices.

LED driver modules, responsible for regulating the current and voltage supplied to LED lighting systems, harness the capabilities of aluminum PCBs. This synergy results in energy-efficient illumination that outshines traditional lighting solutions.

In the realm of DC-DC converters, where voltage levels are precisely regulated, aluminum PCBs provide the thermal stability necessary for consistent and reliable power conversion, ensuring our devices receive the optimal energy they require.

From compact power supplies to industrial-grade motor controllers, aluminum PCBs are the unsung heroes, silently dissipating heat and enabling power modules to operate at peak performance. Their thermal excellence is the driving force behind the seamless integration of power into our daily lives.

Helpful Resouces:

Aluminum PCBs Fuel Automotive Excellence

In the fast-paced world of automotive electronics, where performance, safety, and efficiency are paramount, aluminum PCBs have emerged as the unsung champions, propelling innovation to new heights. These advanced boards are the backbone of cutting-edge systems that elevate the driving experience and keep us safer on the roads.

Engine Control Units (ECUs), the brain of modern automobiles, rely on aluminum PCBs to manage critical functions like fuel injection, ignition timing, and emissions control with unwavering precision. By dissipating heat efficiently, these boards ensure optimal performance even in the harshest conditions.

Advanced Driver Assistance Systems (ADAS), the guardians of our safety, leverage aluminum PCBs to power their suite of sensors and components. From lane departure warnings to automatic emergency braking, these systems are empowered by the thermal excellence of aluminum PCBs, providing an extra layer of protection on every journey.

Infotainment systems, once a luxury, have become an integral part of the driving experience. Aluminum PCBs enable these systems to deliver seamless entertainment, communication, and navigation while withstanding the rigors of the road, ensuring an enjoyable and connected ride.

Lighting systems, too, have undergone a transformation, with LED technology illuminating our paths with unparalleled brightness and efficiency. Aluminum PCBs play a pivotal role in these systems, managing the thermal demands of LED arrays and ensuring optimal visibility for drivers and pedestrians alike.

From the sleekest electric vehicles to the most powerful performance cars, aluminum PCBs are the silent partners, dissipating heat and enabling automotive electronics to operate at their peak. With each mile, they contribute to a safer, more efficient, and more exhilarating driving experience.

Related Reading: Applications of PCBs in Automotive Electronics

Aluminum PCBs Powering Diverse Industries

While LED lighting, power modules, and automotive electronics are undoubtedly the flagbearers of aluminum PCB adoption, these versatile boards have found their way into a myriad of other industries, showcasing their unparalleled capabilities and driving innovation across diverse sectors.

In the realm of industrial control systems, where precision and durability are non-negotiable, aluminum PCBs have emerged as the backbone of manufacturing processes. From intricate machinery to large-scale production lines, these boards handle intense heat and withstand the rigors of industrial environments, ensuring seamless operations and minimizing downtime.

The medical field, a domain where reliability is paramount, has embraced aluminum PCBs as the foundation for cutting-edge devices such as MRI, ultrasound, and X-ray machines. By efficiently dissipating heat, these boards contribute to the accurate and consistent performance of life-saving diagnostic equipment.

Telecommunications, the lifeblood of modern connectivity, relies on aluminum PCBs to power base stations, routers, and switches. These boards ensure uninterrupted data transmission and unwavering network performance, keeping us connected in an increasingly digital world.

In the aerospace and defense sectors, where harsh environments and extreme conditions are the norm, aluminum PCBs have proven their mettle. These rugged boards withstand intense thermal stress, vibrations, and shocks, making them the ideal choice for mission-critical systems that demand unwavering reliability.

Even in the realm of consumer electronics, where sleek designs and high performance converge, aluminum PCBs have left their mark. From smartphones and tablets to laptops and gaming consoles, these boards enable compact yet powerful devices, ensuring optimal thermal management and prolonged battery life.

Across industries, aluminum PCBs have become the unifying force, enabling technological advancements and driving innovation with their exceptional thermal capabilities and enduring resilience. As technology continues to evolve, these versatile boards will undoubtedly continue to power a diverse array of applications, pushing the boundaries of what is possible.

Related Reading:

Advantages of Using Aluminum PCB

In the ever-evolving landscape of electronics, where innovation and performance are paramount, aluminum PCBs have emerged as the game-changers, offering a host of unparalleled advantages that propel technology to new heights. These advanced boards are more than just a substrate; they are the catalysts that unlock a world of possibilities.

- Thermal Mastery: Aluminum PCBs boast unrivaled thermal conductivity, a trait that sets them apart from their conventional counterparts. This unmatched ability to dissipate heat ensures that even the most power-hungry components operate at peak efficiency, minimizing the risk of overheating and prolonging the lifespan of electronic devices.

- Rugged Durability: These boards are built to withstand the rigors of harsh environments, thermal stress, and the relentless demands of mission-critical applications. From scorching deserts to freezing tundras, aluminum PCBs remain steadfast, ensuring reliable performance where others falter.

- Lightweight Champions: Defying the conventions of traditional PCBs, aluminum variants offer a lightweight yet robust construction, making them the ideal choice for applications where weight is a critical factor, such as aerospace, portable electronics, and wearable devices.

- Cost-Effective Pioneers: While delivering unparalleled performance, aluminum PCBs also offer a cost-effective solution, appealing to manufacturers seeking to optimize expenses without compromising on quality or functionality.

- Design Flexibility: With their unique properties, these boards empower engineers to push the boundaries of design, enabling the creation of unique shapes, compact configurations, and innovative form factors that were once thought impossible.

As technology continues to advance, aluminum PCBs stand as the vanguards, enabling the realization of ambitious projects and driving innovation across industries. Their unrivaled advantages have made them the preferred choice for engineers and manufacturers seeking to unlock the true potential of their electronic devices.

The Aluminum PCB Frontier: Blazing the Trail Ahead

Aluminum PCBs stand at the vanguard of innovation, reshaping the electronics industry with their unparalleled thermal capabilities and trailblazing performance. From high-powered LED lighting to cutting-edge automotive systems, these advanced boards have become indispensable, enabling technological breakthroughs while upholding sustainability and efficiency.

As the demand for compact, high-performance electronics continues to soar, aluminum PCBs will undoubtedly play a pivotal role in driving progress. Their unique advantages, including superior heat dissipation, lightweight construction, and design flexibility, position them as the catalysts for realizing ambitious projects across diverse sectors.

At JHYPCB, we are at the forefront of this aluminum PCB revolution. Our state-of-the-art facilities and experienced team provide end-to-end solutions, from rapid aluminum PCB prototype to high-volume PCB manufacturing and assembly. With a deep commitment to quality and innovation, we empower businesses to bring their cutting-edge designs to life, leveraging the full potential of aluminum PCBs.

Whether you’re a startup seeking to prototype your next groundbreaking product or an established brand looking to streamline your manufacturing processes, JHYPCB is your trusted partner. We combine our expertise with the unparalleled capabilities of aluminum PCBs to deliver solutions that push the boundaries of what’s possible in the world of electronics.

Join us on this exciting journey as we blaze the trail ahead, harnessing the power of aluminum PCBs to shape a future where innovation knows no bounds.