According to different classification standards, copper-clad laminates can be classified in different ways. Generally, they are divided into two categories: rigid copper-clad laminates (CCL) and flexible copper-clad laminates (FCCL) based on the mechanical rigidity of the copper-clad laminate. FCCL, also known as flexible copper clad laminate or soft copper clad laminate, is a type of material made by bonding a copper foil and a PI film through certain methods, which can be further processed into a flexible printed circuit board (FPC). Compared with rigid copper-clad laminates, FCCL has the advantages of being thin, light, and flexible, and especially when made with polyimide film, it also has excellent electrical and thermal performance, as well as good heat resistance. Its relatively low dielectric constant (Dk) property allows for rapid transmission of electrical signals. Good thermal performance makes components easy to cool. The higher glass transition temperature (Tg) allows components to operate at higher temperatures. Since most FCCL products are supplied to users in the form of continuous rolls, using FCCL to produce printed circuit boards is favorable for achieving automated continuous production of FPC and continuous surface mounting of components on FPC.

PCB Materials

Flexible Copper Clad Laminate (FCCL)

FCCL, short for Flexible Copper Clad Laminate, is a type of flexible printed circuit board (FPCB) material. Our FPCB manufacturing service provides comprehensive support from bare flexible PCB production to final assembly, aiming to deliver high-quality and highly reliable solutions for flexible circuit boards.

What is Flexible Copper Clad Laminate (FCCL)?

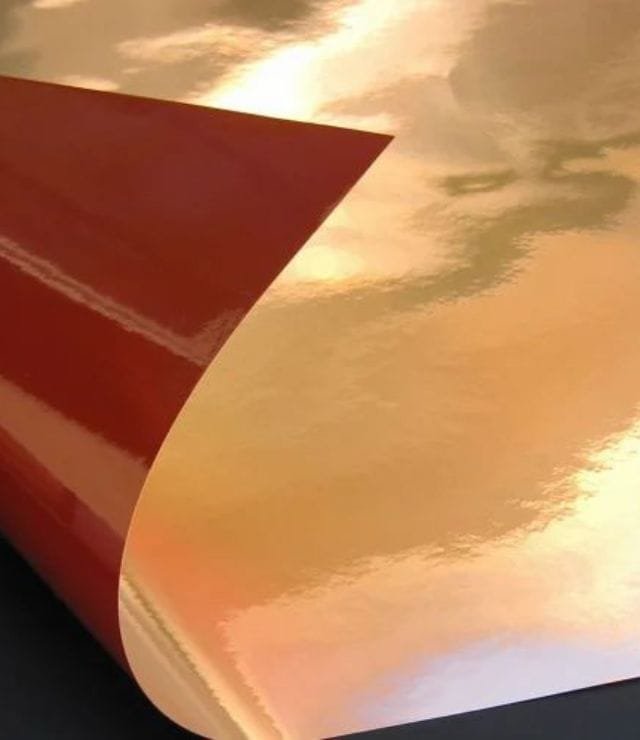

Flexible Copper Clad Laminate (FCCL) is a material that is used to make flexible printed circuit boards. It is a combination of a flexible polymer layer and a copper foil layer. The polymer layer provides flexibility and allows the FCCL to bend, twist or fold, while the copper foil layer provides electrical conductivity.

Flexible Copper Clad Laminate is a critical component in the manufacturing process of flexible PCBs. Without it, flexible PCBs would not be possible. The FCCL allows for the creation of high-density circuits with components mounted on both the top and bottom layers of the board, as well as on the flexible polymer layer.

FCCL is also known as flexible circuit board material, flexible copper laminate, flexible copper clad board, and flexible copper clad material.

Bendable and flexible PCBs are in high demand due to their ability to be molded in different shapes and sizes, making them ideal for use in many modern electronic devices such as wearable technology, mobile phones, and medical devices.

Types of Flexible Copper Clad Laminate

Flexible Copper Clad Laminate can be classified based on its material composition, structure, and other characteristics. Here are some different types of FCCL:

1. Material-based Classification:

- Polyimide (PI) FCCL: This type of FCCL uses a polyimide film as a substrate and exhibits good thermal stability, flexibility, and chemical resistance.

- Polyester (PET) FCCL: PET FCCL is made using a polyester film substrate and has good dimensional stability, flexibility, and cost-effectiveness.

- PEN FCCL: PEN FCCL is made using a polyethylene naphthalate (PEN) substrate and has excellent thermal and dimensional stability, high-temperature resistance, and flexibility.

- PTFE FCCL: This type of FCCL uses a polytetrafluoroethylene (PTFE) film as a substrate and has excellent thermal stability, chemical resistance, and low dielectric constant.

2. Structure-based Classification:

- Single-sided FCCL: This type of FCCL has copper on one side of the substrate, which provides good electrical conductivity and signal transmission capability.

- Double-sided FCCL: Double-sided FCCL has copper on both sides of the substrate, which increases its conductivity and allows for more complex circuit designs.

- Multi-layer FCCL: Multi-layer FCCL consists of multiple layers of copper-clad substrates, providing higher density and complexity for the circuit design.

3. Adhesive-based classification

Adhesive-based classification can be further divided into two categories: Adhesive-less FCCL ((“2L-FCCL” for short)) and Adhesive FCCL (“3L-FCCL” for short).

- Adhesive-less FCCL is a type of FCCL that does not contain any adhesive layer. Instead, the laminating process depends on the combination of pressure and heat to bond the copper layers with the substrate. Adhesive-less FCCLs have a number of advantages, including high reliability, excellent dimensional stability, and better electrical performance due to the absence of an adhesive layer. However, the manufacturing process for Adhesive-less FCCLs is more complex and expensive compared to Adhesive FCCLs. JHYPCB suggests that, for the manufacture of rigid-flex PCBs, multilayer PCBs, HDI PCBs, impedance-controlled PCBs, and high-density SMDs with coverlay openings, it is recommended to use adhesiveless (or adhesive-less) FCCLs due to their high flexibility and low CTE which provide superior dimensional stability.

- Adhesive FCCL, on the other hand, has a layer of adhesive that is used to bond the copper layers with the substrate. This bonding process is achieved through pressure and heat. Adhesive FCCLs are easier to manufacture and are more cost-effective compared to Adhesive-less FCCLs. However, the adhesive layer may affect the electrical performance of the FCCL, thereby limiting its use in certain applications. JHYPCB recommends the use of adhesive-based FCCLs for the production of simple flex circuits, single-sided flex circuits, and double-sided flex circuits due to their cost-effectiveness.

In addition to the classification based on material composition and structure, Flexible Copper Clad Laminate can also be categorized based on other attributes, such as:

- The thickness of copper foil: FCCL can be divided into thin copper foil FCCL and thick copper foil FCCL.

- Coverlay thickness: FCCL can be categorized as thick coverlay FCCL or thin coverlay FCCL.

- Specific application requirements: FCCL can be divided into high-frequency FCCL, FCCL for LED applications, and FCCL for flexible PCB (FPC).

- Processing method: FCCL can be divided into pressure-sensitive FCCL and heat-resistant FCCL.

- Impedance control method: FCCL can be classified into wired control impedance FCCL and in-plate control impedance FCCL.

The Key Role of FCCL in Flexible PCB Manufacturing

FCCL plays a crucial role in the manufacturing of FPCBs due to its flexibility and excellent electrical properties. FCCL is typically composed of three layers: a copper foil layer, an adhesive layer, and a substrate layer. The adhesive layer makes it possible for the copper foil layer to be bonded to the substrate layer, which is usually made of polyimide or polyester.

As a flexible material, FCCL allows for FPCBs to be bent, twisted, and shaped to fit into a variety of spaces and configurations. Additionally, FCCL has excellent electrical properties such as high dielectric strength, low dissipation factor, and excellent thermal stability. This makes it a preferred choice for applications that require high-operating temperatures and good heat resistance. Additionally, it provides options for using both copper and flexible film substrates, which can help reduce the size and weight of the final product.

What are the advantages of using FCCL?

FCCL is a vital material in the manufacturing of flexible printed circuit boards. Below are some of the features and benefits of FCCL:

- Flexibility for increased design options

FCCL is made of a thin, flexible film or polymer material, which can be easily bent, folded, and twisted to conform to various shapes and sizes. This property of FCCL enables designers to create FPCBs for use in a wide range of applications, including medical devices, consumer electronics, and automotive systems. - Increased durability and reliability

FCCL has a high degree of durability, which helps to ensure the longevity and stability of FPCBs. Despite being flexible, FCCL can withstand bending and flexing over extended periods without cracking, breaking, or losing functionality. Furthermore, FCCL protects underlying circuits from dust, moisture, and other environmental factors, thus preventing damage to the FPCB. - Enhanced thermal and electrical conductivity

FCCL contains copper, which makes it an excellent conductor of both electricity and heat. This property of FCCL helps to ensure that FPCBs can function effectively in environments with high heat and humidity. Additionally, FCCL’s electrical conductivity enables the transmission of signals and data across the FPCB without interference or loss of signal quality.

In summary, FCCL’s flexibility, durability, and enhanced thermal and electrical conductivity make it an essential material for the manufacture of FPCBs. FPCBs made with FCCL can deliver reliable performance and functionality in a wide range of applications and environments.

ED and RA Copper on FCCL

ED and RA Copper are two types of copper foils commonly used in the production of Flexible Copper Clad Laminates.

ED Copper, also known as Electro-Deposited Copper, is produced by depositing copper onto a conducting surface using an electric current. This method results in a fine, uniform grain structure and high ductility, making it ideal for use in PCBs that require fine trace widths and tight tolerances.

On the other hand, RA Copper, or Rolled-Annealed Copper, is made by rolling a copper ingot several times to reduce its thickness and then annealing it to improve its ductility. This type of copper foil is less expensive than ED Copper, but its grain structure is less uniform and its ductility is lower.

In the production of FCCL, the choice of copper foil depends on the specific application and performance requirements. For instance, ED Copper may be preferred for high frequency applications that require low signal loss and stable impedance, while RA Copper may be suitable for general purpose circuits that do not require high precision.

What is the manufacturing process of FCCL?

Flexible copper clad laminates are essential components in modern electronics, offering excellent flexibility and durability for a range of applications. The manufacturing process for these products is complex and requires attention to detail at every stage to ensure the final product meets all necessary specifications. In this section, we will explore the steps involved in manufacturing flexible copper clad laminates, including material selection, coating and copper cladding, pressing and curing, and important manufacturing considerations. Understanding these processes is crucial for anyone working in the electronics industry, from designers to manufacturers to end-users.

Step 1. Material Selection:

The first step in manufacturing flexible copper clad laminates is the selection of raw materials. The choice of materials is critical to the overall performance of the finished product. Typically, the materials used include a copper foil for conducting electricity, a polyimide film or other flexible substrate, and a bonding adhesive.

Step 2. Coating and Copper Cladding:

Once the appropriate materials have been selected, the next step is to apply a thin layer of adhesive to the substrate. Then, a layer of copper is bonded to the substrate to form the base for the circuit. Different methods can be used for applying the copper layer, including electroplating, lamination, or hot pressing.

Step 3. Pressing and Curing:

After the copper layer has been applied, the circuit is then pressed to ensure that it is bonded securely to the substrate. During the pressing process, heat is applied to activate the bonding adhesive and cause it to cure. The pressure and temperature must be carefully controlled to ensure that the materials are not damaged during this step.

Step 4. Manufacturing Considerations:

During the manufacturing process, it is important to keep in mind several factors that can affect the performance of the finished product. The thickness, adhesive properties, and thermal stability of each layer must be carefully controlled to ensure that the final product meets all necessary specifications. Any defects or inconsistencies in the layers can significantly impact the electrical performance and durability of the finished product, so quality control measures and testing procedures are critical to ensuring the final product meets the customer’s needs and specifications.

What are the applications of FCCL?

Flexible circuits are becoming increasingly popular due to their unique ability to bend and flex without breaking. Flexible Copper Clad Laminate is the foundation material used in the manufacturing of these flexible PCBs. FCCL is a composite material made up of a flexible substrate and a thin layer of copper foil. This material is essential for the construction of flexible PCBs and has its own distinct benefits and applications.

The primary use of FCCL is in flexible and rigid-flex PCBs. These types of PCBs are used extensively in the medical, automotive, aerospace, and consumer electronics industries. In medical applications, flexible PCBs are often used in wearable devices that monitor vital signs such as heart rate or blood pressure. They are also used in diagnostic equipment where space is at a premium and flexibility is essential.

In the automotive industry, flexible PCBs are used in electronic control units, sensors, and lighting systems. These PCBs can withstand high temperatures and vibrations, making them an ideal choice for rugged environments. They are used in aerospace applications for their lightweight and flexible properties. Flexible PCBs are also increasingly being used in consumer electronics devices such as smartphones, fitness wearables, and laptops due to their thin and flexible nature.

FCCL also has a number of other applications beyond flexible PCBs. For example, it can be used in antennas and electromagnetic shielding due to its conductive properties. It is also used in touchscreen panels, backlight units, and LED lighting, making it a versatile material with applications across a range of industries.

In conclusion, FCCL is an essential material for the manufacture of flexible and rigid-flex PCBs. It has a broad range of applications across a number of industries due to its flexible and conductive properties, making it a versatile and increasingly popular material choice.

Flexible Copper Clad Laminate Manufacturers

Common FCCL manufacturers in the market include Dupont, Panasonic, Nitto Denko, Taiflex, Shengyi Technology, and others. These manufacturers have a strong influence in the FCCL industry and have a wide customer base.

- Dupont: A long history, fast product line upgrades, and has technological advantages.

- Panasonic: An advantage in thin substrate (economic type).

- Nitto Denko: Complete product line, reasonable price.

- Taiflex: Complete infrastructure, low price, and one of the market leaders.

- Shengyi Technology: Complete product line and competitive advantages in performance and price.

| Flexible Copper Clad Laminate Offered by Shengyi Technology | ||||

|---|---|---|---|---|

| Product Name | Product Description | Dk/10GHz | Df/10GHz | Application |

| SF280 | Used for sub-6G flexible copper clad laminate | 2.92 | 0.0032 | 5G Antenna Module |

| DL | Casting PI Adhesiveless DS flexible copper clad laminate | 3.36 | 0.0057 |

|

| SL | Single side adhesiveless flexible copper clad laminate | 3.22 | 0.004 |

|

| SF201 | Single side adhesiveless flexible copper clad laminate | 3.4 | 0.007 |

|

| SF202 | Double side adhesiveless flexible copper clad laminate | 3.2 | 0.009 |

|

| SF230 | Use for high speed circuit FCCL | 3.2 | 0.005 | 5G |

| SF305 | Halogen-free flame-resistant type PI film based flexible copper clad laminate | 3.6 | 0.028 |

|

| SF701 | Liquid crystal polymer film based flexible copper clad laminate | 2.9 | 0.002 | 5G |

FCCLs in Stock

When it comes to designing flexible printed circuit boards, choosing the right FCCL is crucial for ensuring long-term stability of high-performance electronic devices. We currently offer four types of FCCLs, including single-sided adhesive-less FCCL, single-sided adhesive FCCL, double-sided adhesive-less FCCL, and double-sided adhesive FCCL. We can also assist in combining FCCLs of different thicknesses to meet your specific requirements.

| Adhesive-less FCCL (Single-Sided) | |

|---|---|

| Copper Thickness μm (mil) | Polyimide Thickness μm (mil) |

| 1/2oz – 18 (0.7) | 13 (0.5) |

| 1/3oz – 12 (0.46) | 25 (1) |

| 1/2oz – 13 (0.7) | 25 (1) |

| 1oz – 35 (1.4) | 25 (1) |

| 1/2oz – 18 (0.7) | 25 (1) |

| 1/2oz – 18 (0.7) | 50 (2) |

| 1oz – 35 (1.4) | 50 (2) |

| 1/2oz – 18 (0.7) | 75 (3) |

| 1oz – 35 (1.4) | 75 (3) |

| Adhesive FCCL (Single-Sided) | ||

|---|---|---|

| Copper Thickness μm (mil) | Adhesive Thickness μm (mil) | Polyimide Thickness μm (mil) |

| 1oz – 35 (1.4) | 13 (0.5) | 13 (0.5) |

| 1oz – 35 (1.4) | 25 (1) | 13 (0.5) |

| 1/2oz – 18 (0.7) | 25 (1) | 25 (1) |

| 1oz – 35 (1.4) | 25 (1) | 25 (1) |

| 1/2oz – 18 (0.7) | 25 (1) | 50 (2) |

| 1oz – 35 (1.4) | 25 (1) | 50 (2) |

| Adhesive-less FCCL (Double-Sided) | ||

|---|---|---|

| Copper Thickness μm (mil) | Polyimide Thickness μm (mil) | Copper Thickness μm (mil) |

| 1/2oz – 18 (0.7) | 13 (0.5) | 1/2oz – 18 (0.7) |

| 1/3oz – 12 (0.46) | 25 (1) | 1/3oz – 12 (0.46) |

| 1/2oz – 13 (0.7) | 25 (1) | 1/2oz – 13 (0.7) |

| 1oz – 35 (1.4) | 25 (1) | 1oz – 35 (1.4) |

| 1/2oz – 18 (0.7) | 25 (1) | 1/2oz – 18 (0.7) |

| 1/2oz – 18 (0.7) | 50 (2) | 1/2oz – 18 (0.7) |

| 1oz – 35 (1.4) | 50 (2) | 1oz – 35 (1.4) |

| 1/2oz – 18 (0.7) | 75 (3) | 1/2oz – 18 (0.7) |

| 1oz – 35 (1.4) | 75 (3) | 1oz – 35 (1.4) |

| Adhesive FCCL (Double-Sided) | ||||

|---|---|---|---|---|

| Copper Thickness μm (mil) | Adhesive Thickness μm (mil) | Polyimide Thickness μm (mil) | Adhesive Thickness μm (mil) | Copper Thickness μm (mil) |

| 1oz – 35 (1.4) | 13 (0.5) | 13 (0.5) | 13 (0.5) | 1oz – 35 (1.4) |

| 1oz – 35 (1.4) | 25 (1) | 13 (0.5) | 25 (1) | 1oz – 35 (1.4) |

| 1/2oz – 18 (0.7) | 25 (1) | 25 (1) | 25 (1) | 1/2oz – 18 (0.7) |

| 1oz – 35 (1.4) | 25 (1) | 25 (1) | 25 (1) | 1oz – 35 (1.4) |

| 1/2oz – 18 (0.7) | 25 (1) | 50 (2) | 25 (1) | 1/2oz – 18 (0.7) |

| 1oz – 35 (1.4) | 25 (1) | 50 (2) | 25 (1) | 1oz – 35 (1.4) |

Choosing the Right FCCL for Flexible PCB Manufacturing

When choosing a FCCL for manufacturing flexible PCBs, there are several important factors to consider:

Mechanical Strength: FCCLs need to withstand bending, folding and other mechanical deformations. Therefore, the material should have high tensile strength, tear strength, and resistance to cracking.

Environmental Stability: FCCLs should maintain their electrical properties even in harsh environments with high humidity, temperature changes, or exposure to chemicals. Environmental stability also includes resistance to thermal cycling and UV exposure.

Thermal Stability: Flexible PCBs may need to operate at elevated temperatures. Therefore, FCCLs should have high glass transition temperature (Tg) and low coefficient of thermal expansion (CTE) to withstand temperature cycling.

Electrical Performance: FCCLs need to provide reliable electrical connections between the components on the board. Therefore, low dielectric loss and low dissipation factor are critical for FCCLs, as they help to maintain signal integrity and prevent signal degradation.

Other Important Factors: The overall thickness, copper thickness, peel strength, and flexibility of the FCCL also play important roles when selecting an FCCL. Additionally, considering the availability of the FCCL, quality consistency, and price can also be factors to consider.

What are the difference between FCCL and Rigid CCL?

Flexible Copper Clad Laminate differs from rigid copper-clad laminates in several ways.

Firstly, the base material of FCCL utilizes a flexible substrate, typically made of polyimide or polyester film, while rigid copper clad laminates use a rigid substrate, such as fiberglass.

Secondly, the copper layers in FCCL are typically thinner than those in rigid copper clad laminates, due to the requirements of flexibility.

Thirdly, FCCL can bend and flex without cracking, while rigid copper clad laminates are not flexible and may crack or even break under stress.

These differences give FCCL a unique advantage over rigid copper clad laminates in applications where flexibility is needed, such as in wearable electronics or curved displays.

What is the future of FCCL?

Flexible Copper Clad Laminate is an important material for the manufacturing of flex PCBs which have become increasingly popular in many industries. Looking ahead, FCCL is expected to continue to evolve in several directions.

Firstly, FCCL materials are likely to become thinner and more flexible, with improved electrical and thermal properties. This will allow for greater design flexibility in applications that require thinner and more compact flex PCBs.

Secondly, more environmentally friendly FCCL materials are likely to be developed, since sustainability and environmental protection is becoming a significant concern in many industries. FCCL materials that are recyclable and made from renewable resources are expected to gain popularity in the future.

Thirdly, there is a great potential for FCCL materials to become more compatible with the manufacturing processes of other electronics materials, such as semiconductor devices. This could lead to the development of more seamless integration of flex PCBs into electronic devices.

Lastly, FCCL materials are also expected to become more durable and resistant to external factors, such as mechanical stress, moisture, and chemicals. This will increase the reliability and longevity of flex PCBs, making them suitable for use in various demanding applications.

Overall, the future development of FCCL materials is likely to focus on improving their flexibility, sustainability, compatibility, durability, and performance.

High-Quality and Reliable PCB Manufacturing Services by JHYPCB

As a professional PCB manufacturer in China, JHYPCB provides high-quality PCB manufacturing services, including Rigid PCB manufacturing of up to 64 layers and flexible PCB services that cover single-sided, double-sided, and multilayer flexible circuits.

As one of the leading PCB manufacturers globally, we offer complete PCB solutions to meet diverse customer requirements on product quality, delivery time, and cost control. Our team has years of experience and expertise in the industry, streamlining the PCB manufacturing process through lean production, rigorous management, and quality control. This ensures that every PCB product we deliver meets the highest standards and customer expectations.

If you need high-quality, reliable, and cost-effective PCB products and services that meet various requirements, do not hesitate to contact our sales team. We will provide you with quality service to our fullest extent!

Explore Our PCB Fabrication Services

Related Reading

- What Is A Printed Circuit Board (PCB)?

- PCB Layers Explained: Multilayer PCB Stakcup

- How PCBs Are Made Step By Step?

- PCB Substrate: A Comprehensive Guide To PCB Base Materials

- PCB Prepreg: Definition, Types, Applications, Thickness, And Related Questions Answered.

- What Is Resin Coated Copper?

- Flexible PCB Pricing: Factors, Trends, and Cost-Saving Strategies

- PET vs. PI: the Differences Between these Materials for Flex PCBs

- The Ultimate Guide to Flex PCB Stiffener

- What are the Different Types of Flexible Circuits?

- What are the Materials for Flex Circuits?