Advantages

What are the benefits of use multilayer aluminum PCB?

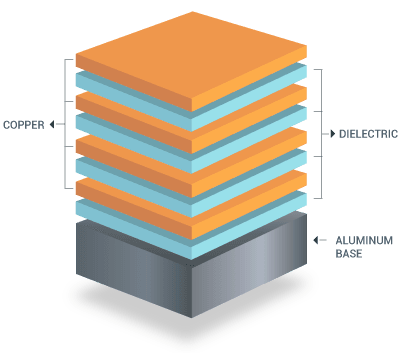

There are several benefits of using Multilayer Aluminum PCBs:

High thermal conductivity

Aluminum has high thermal conductivity, which means it can quickly dissipate heat generated by components on the board, improving the overall reliability and lifespan of the system.

Excellent heat dissipation

The metal core of the Multilayer Aluminum PCB acts as a heatsink, which can effectively dissipate heat from the components to the surrounding environment.