PCB Production Capabilities

PCB Fabrication & Assembly Capabilities of China Manufacturer

PCB Fabrication & Assembly Manufacturer China

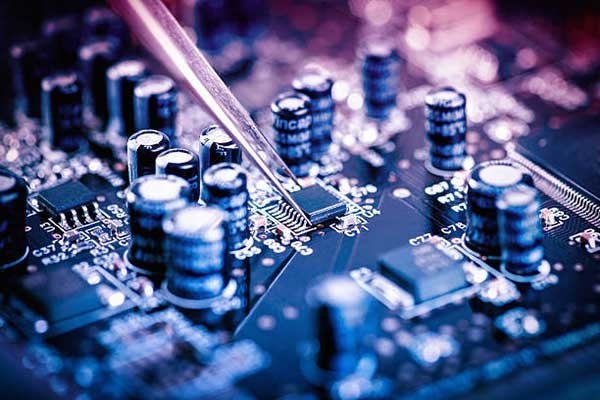

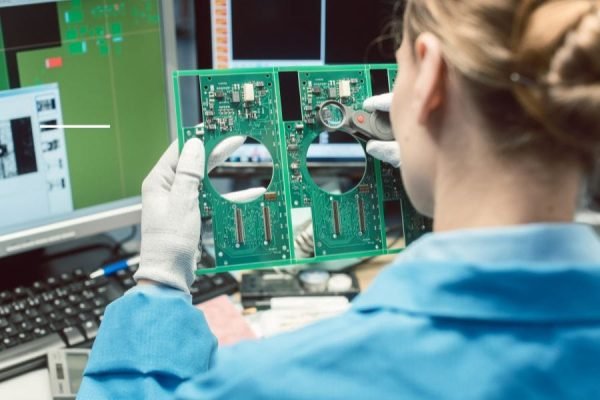

Our advanced PCB manufacturing and assembly capabilities at JHYPCB are the cornerstone of our reputation as a top PCB prototype fabricator since 2011. From producing advanced bare circuit boards to offering complete turnkey prototype PCB assemblies, we take pride in being an industry leader in both quality and performance.

Custom PCB Fabrication Capabilities

JHYPCB, located in Shenzhen, China, is a leading manufacturer of printed circuit boards. With over 10 years of experience, we use the latest technology and equipment to provide advanced PCB manufacturing services while strictly adhering to high-quality standards. Our quality management system is certified by RoHS, ISO 9001:2015, IATF 16949:2016, SGS, and UL.

We specialize in manufacturing PCBs for various industries, including Aerospace, Defense and Military, Telecommunication, Medical, Renewable Energy, and more. Our reliable process and quick turnaround time ensure that we can meet the demand for new types of electronics while providing the best possible cost to our clients.

At JHYPCB, our core competency is providing a hassle-free process from the initial inquiry to the final delivery of the finished circuit boards. Our team of experts anticipates problems before they occur, ensuring that the entire process is smooth and stress-free for our clients. We also offer offshore PCB manufacturing services based on client requirements.

We Delivery the Following PCB Manufacturing Capabilities & Core Competences

- New Production Introduction (NPI)

- Prototype PCB Fabrication

- Rapid PCB Prototyping

- Quick Turn PCB Fabrication

- Small Quantity PCB Production

- High-Volume PCB Manufacturing

- Single Layer, Double Sided, and up to 64 Layers Multilayer PCB

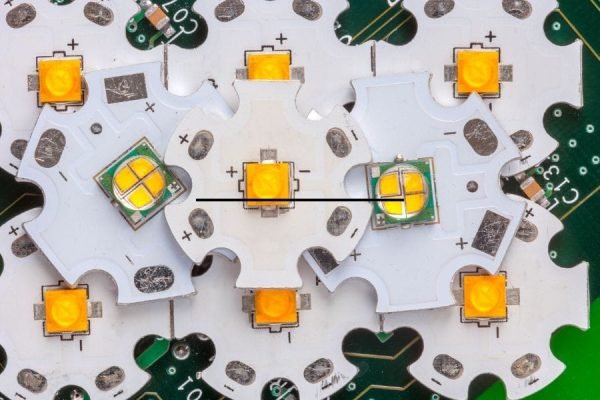

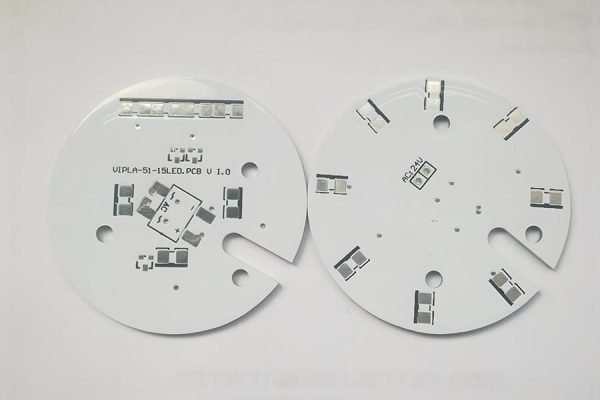

- LED Circuit Board

- Aluminum PCB

- Metal Core PCB

- Copper Core PCB

- Rigid PCB

- Flexible Circuit

- Rigid-Flex PCB

- High-Frequency PCB

- Rogers PCB

- HDI PCB

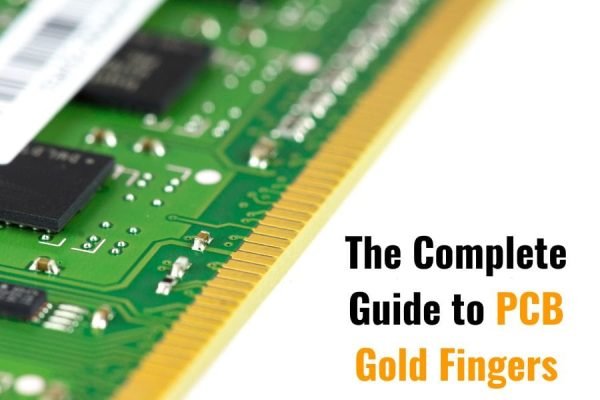

- Golden Fingers PCB

- High-Temperature PCB

- RoHS Printed Circuit Board

- Impedance Controlled PCB

- Heavy Copper PCB

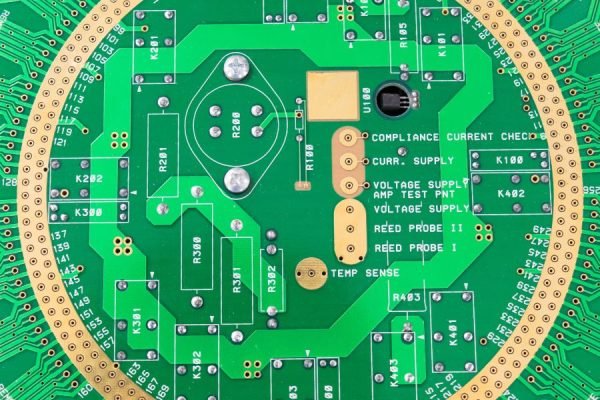

Capabilities

- Quick Turnaround Time

- Prototype Quantities

- Production Runs

- 1-64 Layers

- Rigid, Flex, and Rigid-Flex Boards

- High-density interconnect (HDI)

- 35:1 Drill Aspect Ratio

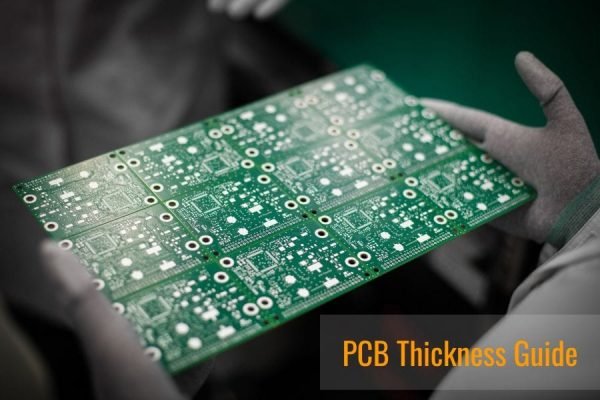

- Board thickness 0.25 ~ 3.20mm

- Maximum Panel Size – 24″ x 31″

- Blind / Buried Vias & Micro Vias

- Via In Pad with Fill Options (non-conductive, conductive)

- High Copper Thickness up to 15oz

- -/+ 5% Impedance Tolerance

- Min. trace width/space 3/3mils

- Edge plating (half-hole)

- IPC Class 2/ Class 3

- Advanced and Exotic Materials

- FR-4

- High-Tg FR-4

- RoHS Compliant Options

- Nelco

- Rogers

- PI

- Shengyi

- IT180

- High-Speed Digital Options

- High-Frequency RF Options

- Aluminum Clad Options

- Copper Core Options

- Immersion Gold (ENIG)

- Immersion Silver

- Immersion Tin

- Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG)

- Hot Air Solder Leveling (HASL)

- Pb-Free HAL

- Organic solderability preservative (OSP)

- Hard Gold

- Soft Gold

- Selective Finishes

- Green

- Black

- Purple

- Orange

- Red

- Blue

- Yellow

- White

- Clear

- In-circuit Testing (ICT)

- Flying Probe Testing (FPT)

- Automated Optical Inspection (AOI)

- X-ray Inspection

- Continuity Testing

- Isolation Testing

- Netlist Testing

- Impedance Testing

- Environmental Testing

Value-Added Services

- Rapid Quote Response

- version management

- DFM Review & Analysis

- Panelization

- Cost Consulting

- Stackup Design

- Surface Finish Consultation

- Laminate and Raw Material Consultation

PCB Assembly Capabilities

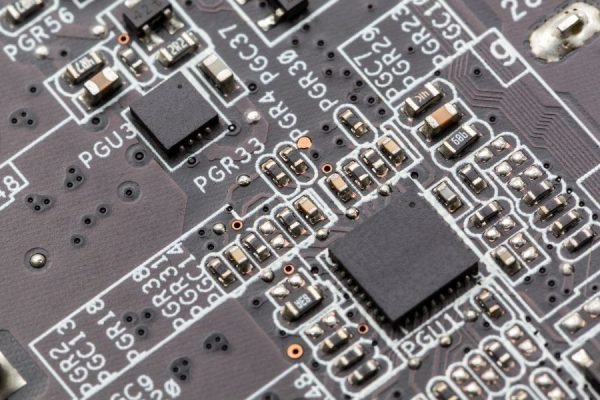

At JHYPCB, we go beyond being just a manufacturer of prototype printed circuit board assemblies. Our assembly services are versatile and include Turnkey Consigned (/Kitted) and Partial Turnkey (/Combo) options that cater to your needs from prototyping to low to high-volume PCB assembly. Our capabilities range from through-hole technology (THT) to single-sided and double-sided surface mounting technology (SMT) assembly.

Our comprehensive in-house PCB Assembly Capabilities are designed to meet all your soldering requirements for rigid, metal core (IMS PCB), flex, and rigid-flex PCBs. Learn all about PCB Assembly Capabilities, JHYPCB is a reliable source for you to learn more about PCB Assembly Capabilities.

One-stop PCB Assembly Services

At our company, we procure components from chip manufacturers worldwide, including Mouser, Digi-Key, Arrow Electronics, and other reputable suppliers. We also maintain a substantial inventory of commonly used parts in our warehouse. If we encounter difficulties in sourcing a specific component, our team of engineers can suggest alternative options that offer fair pricing.

Full Turnkey Assembly Services

JHYPCB offers comprehensive full turnkey PCB assembly services, including PCB fabrication, component sourcing, assembly, testing, and packaging, providing customers with a one-stop solution for their PCB assembly needs.

Partially Consigned Assembly

Partially consigned assembly means the customer provides some or all of the required components. While JHYPCB takes care of the PCB fabrication, assembly, testing to ensure a high-quality end product.

Consigned Assembly Service

The PCB designer provides all components. JHYPCB will fully assemble your printed circuit boards and ship them to you. Quick turnaround times are available, with fully transparent pricing.

Our Full PCB Assembly Services are as the Follows:

- SMT Assembly

- LED PCB Assembly

- BGA Assembly

- Through-hole PCB Assembly

- Turnkey PCB Assembly

- Consigned PCB Assembly

- Cable Harness / Assembly

- Lead-Free PCB Assembly

- SMT Stencil

- Prototype PCB Assembly Service

- Quick Turn PCB Assembly

- Flexible PCB Assembly

- Rigid-Flex PCB Assembly

- Small Quantity PCB Assembly

- High-Volume PCB Assembly

- Component Sourcing

- PCB Assembly Rework

Assembly Services

- NPI: New Product Introduction (NPI)

- SMT: Surface Mount Assembly, Single & Double-sided

- Plated Through-hole: Selective Soldering

- Mixed Technologies: SMT, Through-hole

- Flying Probe Test (FPT)

- Functional Test

- Burn-in Test

- First Article Inspection (FAI)

- Solder Paste Inspection (SPI)

- Automated Optical Inspection (AOI)

- X-Ray Inspection

- Visual Inspection

JHY PCB Assembly Capacity List

PCB Assembly Technology:

- Surface Mount Technology (SMT)

- Through Hole Technology (THT)

- Mixed PCB Assembly Technology

- Single or double-sided Placement

PCB Types:

- Rigid PCB Boards

- Flexible Circuit Boards

- Rigid-Flex PCBs

- Metal Core PCBs

Soldering Types:

- Reflow Soldering

- Wave Soldering

- selective wave soldering

- Manual Soldering

Components Sourcing:

- Full Turnkey

- Partial Turnkey

- Consigned/kitted

Component Size:

- Smallest Components

- Micro BGA

- Fine Pitch Components

- 0201 chip packages

- 0.4 mm pitch BGA

- 0.4 mm fine pitch

Component Package:

- Reels

- Tube and tray

- Cut tape

- loose parts and bulk

SMT Stencils:

- Nano-coating Stencils

- Laser-cut Stainless Steel Stencils

Assembly Process:

- Lead-free (RoHS)

- Leaded

Testing & Inspection:

- Automated Optical Inspection (AOI)

- Manual Visual

- X-Ray

- Flying Probe testing

- ICT Testing

- Functional Testing

- Burn-in Testing

Turn Time:

- Scheduled delivery

- Assembly without components sourcing – 1-5 days

- Turnkey assembly (sourcing+assembly) – 1-2 weeks

- The final lead time for a circuit board assembly order is sourcing lead time +assembly time.

Volume:

- No minimum order quantity

- Engineering prototypes PCB assembly

- Low-volume PCB assembly

- High-volume PCB assembly

Testing & Inspection:

- Automated Optical Inspection (AOI)

- Manual Visual

- X-Ray

- Flying Probe testing

- ICT Testing

- Functional Testing

- Burn-in Testing

If you require PCB assembly services, it’s important to choose a provider with a track record of delivering high-quality products, quick turnarounds, and a willingness to adopt new technologies. Understanding the capabilities of modern-day circuit board assemblers is key to narrowing down your options and finding the best electronic circuit board assembly service for your needs.

JHYPCB offers comprehensive PCB fabrication and assembly services, including advanced capabilities for printed circuit board assembly. As a trusted assembler, we offer competitive pricing for your entire project, including PCB assembly, manufacturing, component sourcing, IC programming, and functional testing.