4 Layer PCB Stackup

4 layer PCB Manufacturing Service

JHYPCB provides high-quality 4-layer PCB prototype and manufacturing services. We offer competitive pricing and fast turnaround times to meet your needs, whether you require a small batch of prototypes or a large production run. With JHYPCB, you can expect high-quality PCBs that meet your exact specifications on time and within budget.

Trusted 4 Layer PCB Manufacturer

JHYPCB is a professional PCB manufacturer that offers high-quality, high-performance PCB manufacturing services, including 4-layer PCB manufacturing. With years of experience and expertise, we specialize in providing the best PCB solutions for our clients.

Our 4-layer PCB manufacturing services provide high-quality PCB fabrication for both prototypes and batch production. We use the latest PCB manufacturing technology and processes to produce high-quality, highly reliable 4-layer PCBs while ensuring on-time delivery. Our 4-layer PCB manufacturing services can be used for various applications, including consumer electronics, industrial automation, medical devices, aerospace, and more.

As a professional 4-layer PCB manufacturer, our company has modern manufacturing equipment and professional production staff. We have a complete PCB manufacturing process, from PCB manufacturing to assembly and testing and from PCB prototype to production runs. We provide comprehensive services to ensure that our clients’ needs are met.

We aim to become one of our client’s most trusted PCB manufacturing suppliers. We aim to provide the best PCB manufacturing services with integrity, professionalism, innovation, and service. We look forward to working with you to achieve mutual development.

What is 4 Layer PCB?

A 4-layer PCB is a type of multilayer printed circuit board that consists of four layers of conductive material separated by insulating layers. These layers are typically made of fiberglass-reinforced epoxy laminate, a composite material that provides both electrical insulation and mechanical support.

The conductive layers create electrical connections between the components on the PCB. In contrast, the insulating layers isolate the conductive traces and prevent electrical interference. The four layers in a 4-layer PCB are arranged in a specific order, with the outer layers used for signal routing and the inner layers used for power and ground planes.

4-layer PCBs, such as smartphones, computers, and other advanced electronic devices, are commonly used in electronic devices that require complex circuitry and high-performance specifications. They provide more space for routing and allow for more complex circuit designs than a 2-layer or 3-layer PCB. Also, 4-layer PCBs offer better signal integrity, lower electromagnetic interference, and higher reliability than single-layer or double-layer PCBs.

What are the Advantages of 4 Layer PCB?

4 layer PCBs offer several advantages over other types of PCBs:

Increased Functionality: 4 layer PCBs provide more space for routing and components, allowing for increased functionality and more complex circuit designs.

Better Signal Integrity: The additional layers in a 4 layer PCB can be used to create power and ground planes, reducing electromagnetic interference and improving signal integrity.

Improved Thermal Management: The additional layers in a 4 layer PCB can be used to create thermal vias and thermal pads, improving heat dissipation and reducing the risk of overheating.

Cost-Effective: 4 layer PCBs are generally more cost-effective than higher layer count PCBs, while still providing many of the same benefits.

Small Form Factor: 4 layer PCBs are ideal for applications where space is limited, as they provide more routing and component options in a smaller form factor.

Easy to Manufacture: Compared to higher layer count PCBs, 4 layer PCBs are relatively easy to manufacture and assemble, reducing the risk of manufacturing errors and improving overall quality.

Overall, 4 layer PCBs offer several advantages over other types of PCBs, making them an excellent choice for a wide range of applications. Contact us today to learn more about how JHYPCB can help with your 4 layer PCB needs.

4 Layer PCB Manufacturing Service

We specialize in providing customized 4-layer PCB solutions that meet the unique needs of our clients. With our advanced technology and processes, we ensure that every PCB we produce meets the highest quality standards. Whether you need a small batch of prototypes or a large production run, we can deliver high-quality PCBs that meet your exact specifications.

4 Layer PCB Prototype

At JHYPCB, we offer high-quality 4-layer PCB prototype services to help you bring your designs to life. Our advanced technology and experienced team ensure that every prototype we produce meets the highest quality standards.

With our 4-layer PCB prototype service, you can enjoy fast turnaround times, competitive pricing, and exceptional quality. We understand that time-to-market is critical for your success, and we strive to deliver your prototypes as quickly as possible without compromising on quality.

We specialize in providing customized 4-layer PCB solutions that meet the unique needs of our clients. Whether you need a small batch of prototypes for testing or a larger run for product development, we can deliver high-quality PCBs that meet your exact specifications.

Cheap 4 Layer PCB

JHYPCB offers cheap 4 layer PCB manufacturing services without compromising on quality. Our cost-effective solutions are perfect for those looking to save money on their PCB production without sacrificing on reliability or performance.

Our cheap 4 layer PCBs are manufactured using high-quality materials and advanced technology, ensuring that they meet the same high standards as our more expensive PCBs. We offer a range of customization options to meet your specific needs, including board size, copper weight, surface finish, and more.

With JHYPCB, you can expect cheap 4 layer PCBs that meet your exact specifications, on time and on budget. Whether you need a small batch of prototypes or a larger production run, we can deliver cheap 4 layer PCBs that meet your unique needs and requirements.

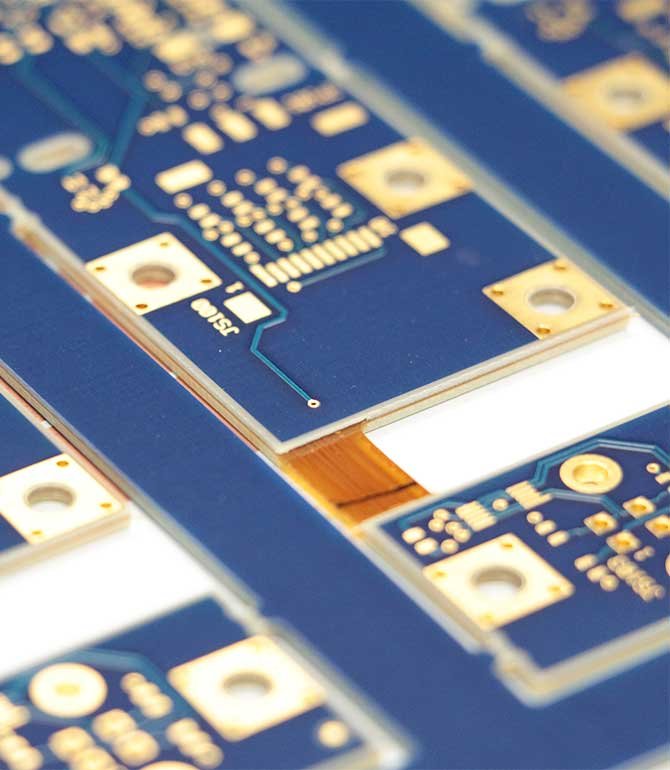

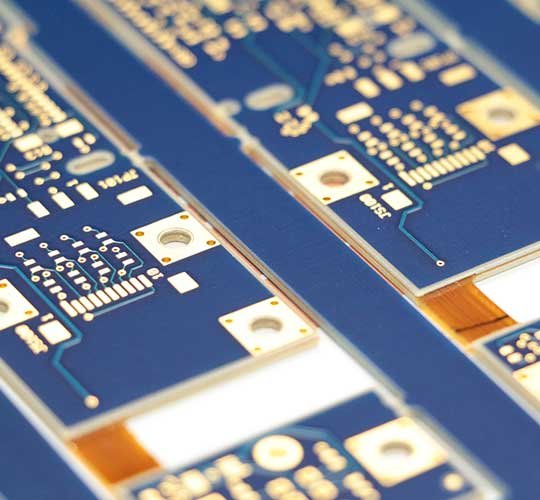

4 Layer Rigid-Flex PCB

At JHYPCB, we offer high-quality 4-layer rigid flex PCB manufacturing services for a wide range of applications. Our advanced technology and experienced team allow us to produce rigid flex PCBs that are durable, reliable, and of exceptional quality.

With JHYPCB, you can expect high-quality 4-layer rigid flex PCBs that meet your exact specifications, on time and on budget. Whether you need a small batch of prototypes or a larger production run, we can deliver rigid flex PCBs that meet your unique needs and requirements.

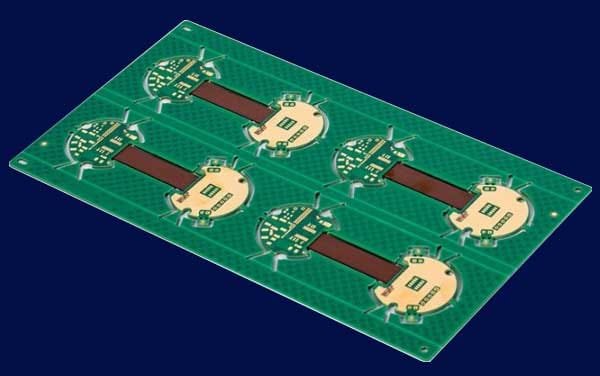

4 Layer Flex PCB Manufacturer

JHYPCB offers high-quality 4-layer flex PCB fabrication services for various applications. Our advanced technology and experienced team allow us to produce flexible PCBs that are durable, reliable, and of exceptional quality.

We specialize in providing customized 4-layer flex PCB solutions that meet the unique needs of our clients. Our flex PCBs are designed to be flexible, making them ideal for applications that require bending or twisting. With our advanced technology and processes, we ensure that every flex PCB we produce meets the highest quality standards.

Our 4-layer flex PCB fabrication service includes various options to meet your needs, including material selection, board size, copper weight, surface finish, and more.

4 Layer PCB Manufacturing Capability

JHYPCB is a leading manufacturer of high-quality 4-layer PCBs. Our state-of-the-art facility and experienced team allow us to offer fast turnaround times, competitive pricing, and exceptional quality.

Our manufacturing capabilities include:

- PCB layer count: 4

- Board size: up to 600mm x 800mm

- Board thickness: 0.4mm – 3.2mm

- Material: FR-4, Rogers, etc.

- Copper weight: 1/2 oz – 6 oz

- Surface finish: HASL, ENIG, OSP, Immersion Silver, etc.

- Minimum trace and spacing: 0.1mm

- Minimum hole size: 0.2mm

- Learn more about our PCB capabilities.

4 Layer PCB Manufacturing Process

Our 4-layer PCB manufacturing process is designed to ensure that every PCB we produce meets the highest quality standards. Our process includes:

- File submission and review

- Pre-production DFM check

- Inner layer imaging and etching

- Drilling and plating

- Outer layer imaging and etching

- Surface finish and solder mask application

- Final electrical testing and inspection

Why Choose Us for 4 Layer PCB Fabrication?

There are several reasons why you should choose JHYPCB for your 4 layer PCB fabrication needs:

High-Quality PCBs: We use only the highest quality materials and advanced technology to manufacture our 4 layer PCBs, ensuring that they meet the highest standards of quality and reliability.

Customization: We offer a range of customization options to meet your specific needs, including board size, copper weight, surface finish, and more.

Competitive Pricing: We offer competitive pricing for our 4 layer PCB fabrication services without sacrificing on quality or reliability.

Experienced Team: Our team of experts has years of experience in the PCB manufacturing industry and is dedicated to providing excellent customer service and support throughout the entire process.

On-Time Delivery: We understand the importance of timely delivery and strive to deliver your 4 layer PCBs on time, every time.

Quality Control: Our quality control processes ensure that every 4 layer PCB we manufacture meets the highest standards of quality and reliability.

Industry Certifications: We hold industry certifications such as ISO 9001:2015 and UL, ensuring that our manufacturing processes meet the highest standards of quality and safety.

At JHYPCB, we are committed to providing high-quality, reliable 4 layer PCB fabrication services that meet your specific needs and requirements. Contact us today to learn more about how we can help with your next project.

FAQs For 4 Layer PCB

What is a 4 layer PCB?

A 4 layer PCB is a printed circuit board that has four conductive layers, with two internal layers that are used for power and ground planes.

What are the benefits of using a 4 layer PCB?

Some benefits of using a 4 layer PCB include increased functionality, better signal integrity, improved thermal management, cost-effectiveness, small form factor, and ease of manufacturing.

What are the common applications of 4 layer PCBs?

4 layer PCBs are commonly used in a variety of applications, including telecommunications, medical devices, industrial equipment, consumer electronics, and more.

What is the typical thickness of a 4 layer PCB?

The typical thickness of a 4 layer PCB is between 0.062 and 0.125 inches, depending on the specific application and design requirements.

What is the maximum number of layers for a PCB?

The maximum number of layers for a PCB can vary depending on the specific application and design requirements. However, modern manufacturing techniques have made it possible to create PCBs with dozens or even hundreds of layers.

As a senior multi-layer PCB manufacturer and supplier, we can produce up to 64 layers of printed circuit boards

What materials are used in 4 layer PCB manufacturing?

The materials used in 4 layer PCB manufacturing can vary depending on the specific application and design requirements. However, common materials include FR-4, polyimide, and high-temperature laminates.

Can you provide both 4 layer PCB prototype and manufacturing services?

Yes, JHYPCB can provide both 4 layer PCB prototype and manufacturing services to meet your specific needs and requirements.

What is the typical lead time for 4 layer PCBs?

The typical lead time for 4 layer PCBs can vary depending on the specific application and design requirements. However, JHYPCB offers fast turnaround times to ensure that your project is completed on time.

Explore Our PCB Fabrication Services

Related Reading

- PCB Gerber Files – Everything You Need to Know

- Building High Quality PCBs – A Comprehensive Guide

- Material selection and performance of multilayer PCBs: how to balance cost and performance

- Multilayer PCB Manufacturer: How to Choose the Right One for Your Project?

- Multilayer PCB Design Guide: A Comprehensive Overview

- What Are The Benefits And Applications of Multilayer PCB?

- A Guide to Multilayer PCB Manufacturing Process

- PCB Layers Explained: Multilayer PCB Stakcup

- A Comprehensive Guide to 8-Layer PCB Stackup Design