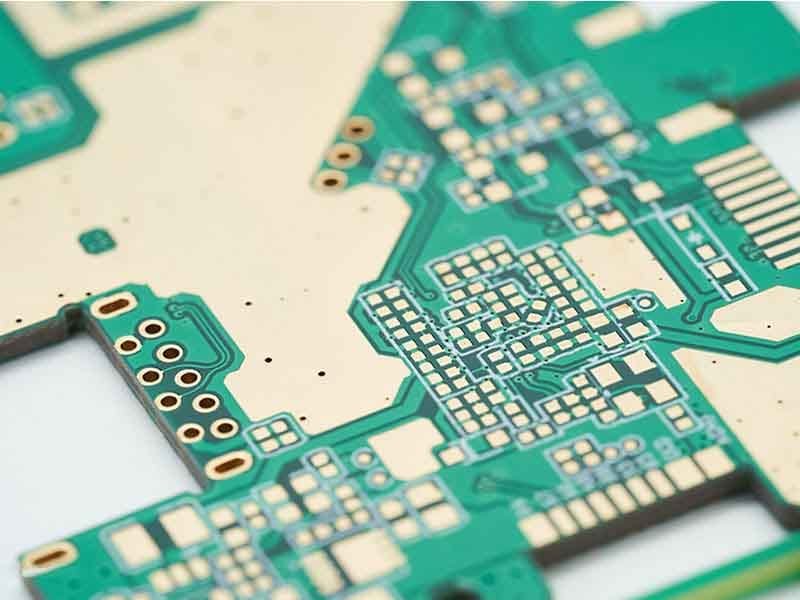

In the ever-evolving world of electronics, high-performance PCBs have become an indispensable component across industries. Among these, high Tg PCBs, or high glass transition temperature PCBs, stand out as a game-changer, offering unparalleled capabilities to withstand extreme conditions and deliver superior performance.

These high-temperature circuit boards are engineered with advanced materials that can withstand temperatures well beyond the limits of traditional PCBs, making them an ideal choice for applications in harsh environments. From aerospace and automotive to telecommunications and industrial sectors, the demand for high Tg PCBs continues to soar as manufacturers strive to create more reliable, durable, and high-performing electronic systems…

What is a High Tg PCB?

A high Tg PCB refers to a printed circuit board made with materials that have a higher glass transition temperature (Tg). The glass transition temperature is the point at which a material transitions from a glassy solid state to a more rubber-like state. High Tg PCBs use base materials and copper foils with a Tg value typically above 170°C, significantly higher than the 120-130°C range of standard FR-4 and other conventional materials.

This high Tg characteristic gives high Tg PCBs superior high-temperature performance. In extreme high-temperature environments, high Tg PCBs can maintain excellent dimensional stability and insulation reliability without experiencing the softening, deformation, and deterioration of dielectric properties that normal PCBs suffer from. Beyond heat resistance, high Tg PCBs also offer improved moisture resistance and chemical resistance.

In essence, high Tg PCBs extend the temperature range that PCBs can withstand while improving reliability and service life, making them the ideal choice for applications with special environmental requirements…

Unparalleled Advantages of High Tg Printed Circuit Boards

When it comes to mission-critical applications that demand exceptional performance and reliability, high Tg PCBs stand out as the ultimate solution. These advanced circuit boards offer a remarkable set of advantages that set them apart from traditional PCBs, making them the go-to choice for harsh environments and demanding applications.

- Higher Glass Transition Temperature for Extreme Heat Resistance

At the core of high Tg PCBs lies their ability to withstand extreme temperatures. With a glass transition temperature typically exceeding 170°C, these heat-resistant PCBs maintain their structural integrity and insulation properties even in the most scorching conditions, outperforming standard FR-4 boards that can degrade at high temperatures. - Improved Mechanical Strength and Rigidity

High Tg PCBs boast superior mechanical strength, thanks to their rigid molecular structure. This increased stiffness and robustness make them highly resistant to stress, impact, and vibration, ensuring reliable performance in demanding industrial, automotive, and aerospace applications. - Better Thermal Stability to Prevent Warping and Delamination

Conventional PCBs are susceptible to warping and delamination when exposed to high temperatures, compromising their performance and longevity. High Tg PCBs, however, offer exceptional thermal stability, preventing these issues and ensuring dimensional accuracy even in extreme thermal environments. - Lower Signal Loss for High-Frequency Applications

The advanced materials used in high Tg PCBs exhibit lower loss tangents and better dielectric properties, resulting in reduced signal attenuation. This makes them an ideal choice for high-frequency and high-speed applications, such as telecommunications, radar systems, and data communication networks. - Improved Moisture and Chemical Resistance

In addition to their thermal resilience, high Tg PCBs also demonstrate remarkable resistance to moisture and chemical exposure. This characteristic is crucial for applications where boards may be subjected to harsh environmental conditions or chemical processes, ensuring long-lasting performance and reliability. - Extended Service Life and Potential Cost Savings

By addressing the challenges of high temperatures, vibration, moisture, and chemical exposure, high Tg PCBs offer a significantly extended service life compared to standard PCBs. This longevity translates into potential cost savings over the product’s lifetime, making high Tg PCBs a cost-effective solution for mission-critical applications.

With their exceptional thermal, mechanical, and electrical properties, high Tg PCBs represent the pinnacle of printed circuit board technology, enabling cutting-edge solutions across various industries. Explore the world of high Tg PCBs and unlock new levels of performance, reliability, and durability for your next project.

Unleash the Full Potential: Key Benefits of High Temperature PCBs

High Tg PCBs have revolutionized the electronics industry, offering a robust solution for harsh environments and mission-critical applications. By harnessing the power of advanced materials, these high temperature circuit boards provide a myriad of benefits that transcend the limitations of conventional PCBs. Explore the key advantages that make high Tg PCBs an indispensable choice:

- Suitability for High-Temperature Applications

Engineered to withstand extreme heat conditions, high Tg PCBs are the ideal choice for applications where electronic components are exposed to elevated temperatures. Industries such as automotive, aerospace, and industrial automation rely on these heat-resistant printed circuit boards to ensure reliable performance and longevity in scorching environments. - Compatibility with Lead-Free Soldering Processes

As environmental concerns drive the industry towards lead-free soldering practices, high Tg PCBs seamlessly integrate with these eco-friendly processes. Their robust construction and thermal stability ensure flawless performance during lead-free soldering, aligning with industry standards and regulations. - Reduced Risk of Failure and Increased Reliability

Traditional PCBs often fall victim to failures caused by heat, moisture, or chemical exposure, compromising the reliability of electronic systems. High Tg PCBs mitigate these risks by offering superior thermal stability, moisture resistance, and chemical resilience, resulting in enhanced reliability and reduced downtime. - Improved Signal Integrity for High-Frequency Applications

The advanced materials used in high temperature PCBs exhibit lower loss tangents and better dielectric properties, minimizing signal attenuation. This characteristic is crucial for high-frequency and high-speed applications, such as telecommunications, radar systems, and data communication networks, ensuring optimal signal integrity and performance. - Increased Design Flexibility and Product Longevity

With their exceptional mechanical strength and resistance to delamination, high Tg PCBs offer increased design flexibility, enabling more compact and intricate layouts. Additionally, their extended service life translates into longer product lifespans, reducing maintenance costs and minimizing environmental impact.

By leveraging the benefits of high Tg PCBs, manufacturers can unlock new realms of performance, reliability, and sustainability for their electronic products. Whether it’s aerospace systems, automotive electronics, or industrial automation equipment, these advanced heat-resistant printed circuit boards pave the way for groundbreaking innovations and uncompromising quality.

Discover the transformative power of high temperature PCBs and elevate your next project to new heights of excellence. Explore our comprehensive range of high Tg PCB solutions and experience the future of electronic excellence today.

Blazing New Trails: Versatile Applications of High Temperature PCBs

The exceptional performance of high Tg PCBs has paved the way for their widespread adoption across diverse industries. These heat-resistant circuit boards stand as the ultimate solution for applications demanding unwavering reliability and durability. Explore the realms where high temperature PCBs are pushing boundaries:

- Aerospace: Uncompromising Performance in Extreme Environments

The aerospace industry imposes stringent requirements on electronic systems, necessitating components capable of withstanding extreme temperatures and harsh conditions. High Tg PCBs not only exhibit superior heat resistance but also boast outstanding moisture and chemical resistance, meeting the rigorous standards for aerospace applications and ensuring the safety and reliability of flight systems. - Telecommunications: Laying the Foundation for High-Frequency, High-Speed Performance

High-speed data transmission and high-frequency communication equipment place stringent demands on the performance of printed circuit boards. With their exceptional dielectric properties and low signal attenuation, high temperature PCBs emerge as the ideal choice for these applications, enabling efficient and seamless communication networks. - Automotive Electronics: Meeting Stringent Vehicular Standards

Automotive electronic systems must operate consistently under challenging conditions, including vibration and high temperatures. High Tg PCBs meet the stringent reliability and durability standards set by the automotive industry, ensuring long-lasting and efficient operation of vehicular electronics. - Industrial Automation: Where Reliability is Paramount

Industrial automation systems require unwavering stability and reliability from their components. High Tg PCBs can withstand the harsh industrial environments, enduring high temperatures, vibrations, and chemical exposure, thereby ensuring continuous and uninterrupted operation of automation systems. - Medical Devices: The Foundation for Precision Performance

Precision is a paramount requirement for medical devices, necessitating the use of circuit boards that deliver exceptional performance. With their structural stability and reliable performance, high Tg PCBs are the ideal choice for diagnostic and monitoring equipment, ensuring accurate and dependable operation.

The applications of high temperature PCBs are continually expanding, empowering manufacturers to create fearless electronic products that can thrive in extreme environments and drive innovation. Explore our diverse range of high Tg PCB solutions and propel your project to new heights of excellence.

Unlock Optimal Performance: Key Factors in Selecting High Temperature PCBs

Choosing the right high Tg PCBs is crucial for ensuring your project’s success, especially in harsh environments or demanding applications. With a wide array of materials and design considerations, it’s essential to carefully evaluate the following key factors to unlock the full potential of these heat-resistant circuit boards:

- Material Selection: The Cornerstone of Thermal Resilience

The material type used in high temperature PCBs plays a pivotal role in determining their thermal properties, dielectric performance, and mechanical strength. Advanced materials like polyimide, ceramics, and specialized laminates offer varying glass transition temperatures, thermal conductivities, and coefficients of thermal expansion, impacting the board’s ability to withstand extreme heat and prevent warping or delamination. - Design Considerations: Optimizing for Performance and Reliability

Designing high Tg PCBs requires adherence to specific guidelines to ensure optimal performance and durability. Critical factors such as trace width, spacing, clearance, pad size, and hole placement must be carefully considered in conjunction with the selected material’s properties. Close collaboration with experienced PCB designers and manufacturers is essential to ensure adherence to industry standards and best practices. - Manufacturing Process: Precision Craftsmanship for Flawless Results

The manufacturing process for high temperature PCBs demands precision and expertise. Different materials may require specialized techniques for lamination, drilling, plating, and soldering. Partnering with a reputable PCB manufacturer well-versed in high Tg PCB fabrication processes is crucial to ensure strict adherence to quality standards and flawless execution. - Budget and Cost Analysis: Balancing Performance and Investment

While high Tg PCBs typically carry a higher upfront cost compared to conventional PCBs, their exceptional performance and extended lifespan can translate into significant long-term cost savings. Conducting a comprehensive cost analysis that factors in material selection, design complexity, and manufacturing requirements is essential to strike the right balance between performance objectives and budget constraints.

By meticulously evaluating these key factors, you can make an informed decision and select the optimal high temperature PCB solution tailored to your project’s specific requirements. Unlock the unparalleled potential of high Tg PCBs and propel your application to new heights of performance, reliability, and longevity.

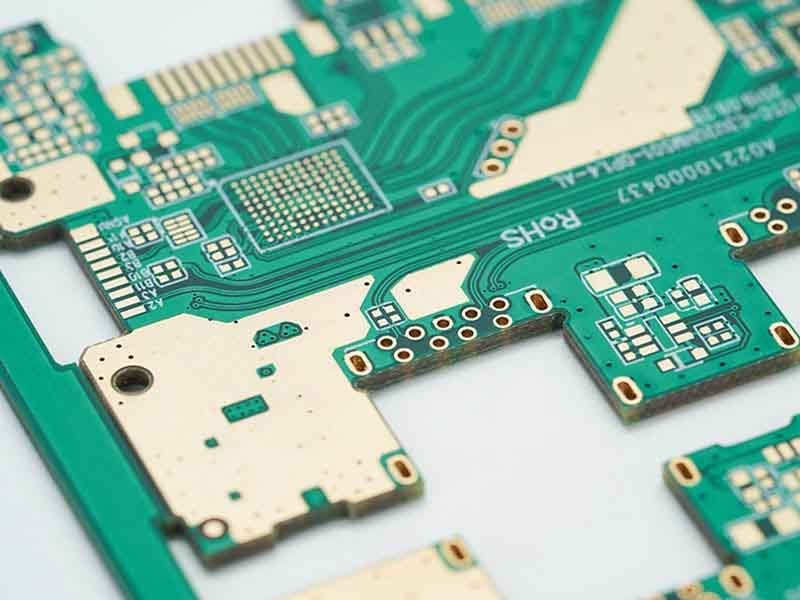

Bring Your High Tg PCB Design to Life with Expert Manufacturing

At JHYPCB, we specialize in transforming your high Tg PCB designs into reality with precision and expertise. As a leading PCB manufacturer, we understand that every project has unique requirements, which is why we offer tailored manufacturing services based on your provided Gerber files and specifications.

Our state-of-the-art facilities and experienced team ensure that your high Tg PCBs are produced with meticulous attention to detail, adhering to the highest quality standards. From material selection to fabrication and assembly, we collaborate closely with you to deliver a customized solution that meets and exceeds your performance expectations.

Don’t compromise on quality or reliability for your mission-critical applications. Partner with JHYPCB, and let us bring your high Tg PCB designs to life with our industry-leading manufacturing capabilities.

“The team at JHY PCB truly understood our complex high Tg PCB requirements and delivered boards that exceeded our expectations.” – Industrial Automation Client Testimonial

Get a Free Quote Today and Experience the JHY PCB Advantage